adaptive control in cnc machine ppt The adaptive control is basically a feedback system that treats the CNC as an . Explore this list of CNC project ideas and learn how you can make money selling your CNC products. With the rise of social media, small businesses can access huge markets. Plus, digital marketing tools make tasks like finding a target audience and building a website easier than ever.

0 · adaptive control system

1 · adaptive control ppt

Steel to Reel is a subscription box aimed at providing its customers with crucial .

The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual .The document discusses computer numerical control (CNC), direct .

sensor distribution box

The adaptive control is basically a feedback system that treats the CNC as an . The document discusses computer numerical control (CNC), direct numerical control (DNC), and adaptive control systems. It describes how CNC replaced conventional NC by using a computer to store machining programs . The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process.

This document discusses adaptive control systems for machining. Adaptive control systems automatically select process control variables based on measurements to overcome limitations of CNC systems. An adaptive .

semi shelf weldment metal housing

Adaptive control systems aim to improve production rates and part quality in machine tools by optimizing machining variables in real-time. Sensors continuously monitor process parameters like tool temperature, cutting forces, .Adaptive control systems originated from research in the 1960s to optimize machining processes. They measure process variables like force, temperature, and vibration and adjust speed or feed rates in real-time. The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process. The proper .• “Adaptive Control” techniques provide a systematic approach for automatic on-line tuning of controller parameters • “Adaptive Control” techniques can be viewed as approximations of .

secure electric meter box

Adaptive Control, a thirty-year old eld, is an advanced control method that is becoming increasingly popular in various engineering applications. The ability to self-correct a controller .

The paper discussed basic classes of adaptive control: adaptive control with optimization (ACO), adaptive control with constraints (ACC), and geometric adaptive control (GAC), as well as. The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process. This document . The document discusses computer numerical control (CNC), direct numerical control (DNC), and adaptive control systems. It describes how CNC replaced conventional NC by using a computer to store machining programs instead of punched tapes. The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process.

This document discusses adaptive control systems for machining. Adaptive control systems automatically select process control variables based on measurements to overcome limitations of CNC systems. An adaptive controller makes feed rate and speed corrections based on measured variables from sensors.

Adaptive control systems aim to improve production rates and part quality in machine tools by optimizing machining variables in real-time. Sensors continuously monitor process parameters like tool temperature, cutting forces, spindle torque, and vibration.

Adaptive control systems originated from research in the 1960s to optimize machining processes. They measure process variables like force, temperature, and vibration and adjust speed or feed rates in real-time. The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process. The proper implementation and role of flexible manufacturing system in current scenario.

adaptive control system

adaptive control ppt

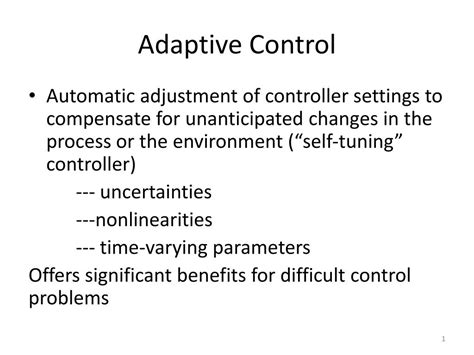

• “Adaptive Control” techniques provide a systematic approach for automatic on-line tuning of controller parameters • “Adaptive Control” techniques can be viewed as approximations of some nonlinear stochastic control problems (not solvable in practice) • Objective of “Adaptive Control” : to achieve and to maintainAdaptive Control, a thirty-year old eld, is an advanced control method that is becoming increasingly popular in various engineering applications. The ability to self-correct a controller in the presence of uncertainties using online information is its main and most compelling feature.

The paper discussed basic classes of adaptive control: adaptive control with optimization (ACO), adaptive control with constraints (ACC), and geometric adaptive control (GAC), as well as.

The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process. This document . The document discusses computer numerical control (CNC), direct numerical control (DNC), and adaptive control systems. It describes how CNC replaced conventional NC by using a computer to store machining programs instead of punched tapes. The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process.

This document discusses adaptive control systems for machining. Adaptive control systems automatically select process control variables based on measurements to overcome limitations of CNC systems. An adaptive controller makes feed rate and speed corrections based on measured variables from sensors.

Adaptive control systems aim to improve production rates and part quality in machine tools by optimizing machining variables in real-time. Sensors continuously monitor process parameters like tool temperature, cutting forces, spindle torque, and vibration.Adaptive control systems originated from research in the 1960s to optimize machining processes. They measure process variables like force, temperature, and vibration and adjust speed or feed rates in real-time.

The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process. The proper implementation and role of flexible manufacturing system in current scenario.• “Adaptive Control” techniques provide a systematic approach for automatic on-line tuning of controller parameters • “Adaptive Control” techniques can be viewed as approximations of some nonlinear stochastic control problems (not solvable in practice) • Objective of “Adaptive Control” : to achieve and to maintainAdaptive Control, a thirty-year old eld, is an advanced control method that is becoming increasingly popular in various engineering applications. The ability to self-correct a controller in the presence of uncertainties using online information is its main and most compelling feature.

seeme cnc replacement parts

security cameras junction box ebay

the metal stars you see on the outside of houses and barns — most commonly found in the more rural parts of the U.S. — actually have a deeper meaning. For one thing, .

adaptive control in cnc machine ppt|adaptive control system