sheet metal sections Basic Principles. Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and . Socialism for the rich and capitalism for the poor" is a classical political-economic argument asserting that, in advanced capitalist societies, state policies assure that more resources flow to the rich than to the poor, for example in the form of transfer payments.Using data from the Survey of Consumer Finances from 1989 through 2019, we show that aggregate comparisons between parents and non-parents mask substantial wealth variation .

0 · types of rolled metal sections

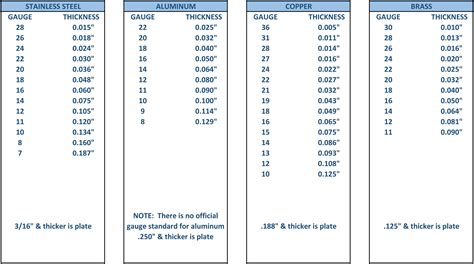

1 · sheet metal thickness chart

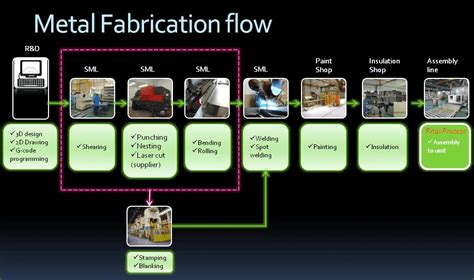

2 · sheet metal manufacturing process

3 · sheet metal fabrication process

4 · sheet metal fabrication pdf

5 · sheet metal fabrication

6 · sheet metal design guide

7 · sheet metal design dimensions

Oldcastle Infrastructure’s underground pull boxes and handholes are the industry’s .

types of rolled metal sections

Rolled steel sections are available in various forms for use in Steel Construction. Shapes, sizes and properties of these rolled steel sections are discussed. .Basic Principles. Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and .There are numerous types of edges, joints, seams, and notches used to join sheet-metal work. We will discuss those that are most often used. Edges are formed to enhance the appearance .Metal Sections (97 products) Add. R 189.00. Stewarts and Lloyds Square Tubing Steel 3000 x 25 x 25 mm. 0.0 out of 5 stars. Delivery. Pickup. Add. R 329.00. Stewarts and Lloyds Square Tubing 3000 x 50 x 50 mm. 0.0 out of 5 stars. Delivery. Pickup. Add. R 499.00. Stewarts and Lloyds Square Steel Tubing 3000 x 76 x 1.6 mm.

Question: Consider the sheet metal cross section shown in ( Figure 1). Suppose that r=1.6 in., a=2.6 in., and b=7.2 in. Part A Determine the location (xˉ,yˉ) of the centroid of the sheet metal cross section. Neglect the thickness of the material .The Sheet metal material selection during product design impact the sheet metal part design, manufacturing process, cost, and part performance. In this article, we will discuss sheet metal materials, their advantages, and their limitations. We can divide the Sheet metal material selection into the following two sections. Selection of sheet thicknessLeading UK manufacturers of roll formed metal profiles Superior Sections has over 25 years-experience manufacturing and supplying roll formed metal profiles for an ever-increasing variety of market sectors and product applications. Products and Applications

SECTION 07620 . SHEET METAL FLASHING AND TRIM . PART 1 - GENERAL 1.1 SUMMARY . A. Section includes the following: 1. Metal flashing. 2. Self-adhering flashing. 3. Formed roof-drainage sheet metal fabrications. 1.2 PERFORMANCE REQUIREMENTS A. General: Install sheet metal flashing and trim to withstand wind loads, structural movement,SHEET METAL SECTION. Introduction Manufacturing processes are the steps through which raw materials or semi-finished products are transformed into a finished or final utility product through different technique process can be classified in. following group likes. Forming process - (Powder Metallurgy, Casting, Plastic Technology) Deforming Process - (Forging, Sheet metal, Rolling, . Sheet metal forming offers malleability, precision (both in the forming processes and parts created), and can be formed with lots of different metals, such as the ones we've outlined in the section above. The created parts are strong, durable, weather-resistant, high load-bearing, and long-lasting. .A section of a round sheet metal elbow, which is basically a straight section cut at an angle at one or both ends. Center Lines. Lines used to show the centers, or axes, of parts or circles shown on a layout. A center line is also used to show the axis of a path of motion. Allowance.

Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. . Notching is a shearing operation that removes a section from the outer edge of the metal strip or part. In case, distance between the notches to bend is very small then distortion of sheet metal may take place. To avoid . In edge bending, the punch forces a cantilevered sheet-metal section over a die edge to obtain the desired bend angle. and more. Study with Quizlet and memorize flashcards containing terms like The three basic types of sheet metalworking operations are (1) cutting, (2) bending, and (3) drawing., The die diameter equals the blank diameter, and .Request PDF | On May 12, 2022, Christian Denkert and others published Fatigue resistance of sheet metal sections generated by press-bolts joints due to cold forming | Find, read and cite all the .

Sheet metal works. Sheet metal work is a deforming process. In this process metal sheets are designed to different shape by applying pressure with different tools, equipment and Machine. A sheet is generally known less thickness and large size .Our guides include: Product Guide – Provides an inspiring overview of the different color solutions that Steelscape offers.; Color Design Guide – A comprehensive overview of modern color trends and finish options for metal roofs and walls.; Metal Wall Design Guide – Designed to enlighten building designers as to the shape and color possibilities available with single skin metal wall .

The best-rated product in Metal Fence Panels is the Quick Screen 7.83 ft x 5.91 ft. x 0.20 ft. Gray Aluminum Side Frame Slate for Fence Panels. What are the shipping options for Metal Fence Panels? All Metal Fence Panels can be shipped to you at home.

In sheet metal design, bend relief refers to a small cut or notch made at the intersection of two bend lines. Its purpose is to prevent material deformation, tearing, and other issues during the bending process. . Self .

created by overlapping two sheet metal sections or by folding them together. hem. created by folding the metal over onto itself to strengthen the edge of a sheet metal object. box and pan. brake that is used to bend all four sides of a sheet metal box. beading.

Sheet Metal Shearing Step #6 – Sheet Metal Seams. Seams are created along the longitudinal length of the duct or fitting to fasten one section to another, as opposed to joints that connect one length of duct section to .AE Project Number: Sheet Metal Flashing and Trim 076200 – 1 Revision Date: 1/29/2014 SECTION 076200 SHEET METAL FLASHING AND TRIM PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this A sheet lifter is a “must-have” piece of equipment for many service centers. They are used to lift and move single or multiple bundles of cut-to- length sheets of steel or aluminum. Every facility is different and therefore there is no “one size fits all” sheet lifter.Sheet metal sections: Our Company is offering quality sheet metals to our customers. We will provide good quality metal sheet with help of our experienced professional team and well-laid infrastructure. We will do sheet metal shearing services, Rolling services, Folding services, Fabrication with reasonable prices. .

Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations., In conventional sheet metalworking operations, (a) what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet-metal part, is the clearance applied to the punch diameter or the .

sheet metal thickness chart

Sheet Metal Sections 70-78 Datsun Z Cars - (Snohomish) . New rust replacement pieces are in the same order as the pics: LH fender bottom section, LH lower door section, LH rocker panel, LH rocker panel back end, LH rear wheel arch, LH quarter panel bottom after the wheel. The same pieces are also available for the RH side.When developing sheet-metal patterns, ensure you add sufficient material to the base dimensions to make the seams. Several types of seams used to join sheet-metal sections are discussed in this section. There are three types of lap seams: the PLAIN LAP seam, the OFFSET LAP seam, and the CORNER LAP seam (fig. 2-66).

SECTION 07620 . SHEET METAL FLASHING AND TRIM . PART 1 - GENERAL 1.1 SUMMARY . A. Section includes the following: 1. Metal flashing. 2. Self-adhering flashing. 3. Formed roof-drainage sheet metal fabrications. 1.2 PERFORMANCE REQUIREMENTS A. General: Install sheet metal flashing and trim to withstand wind loads, structural movement,Learn about our metal roofing panel products. Learn about our metal roofing panel products. Access Billtrust Portal; eCommerce; Employment . This mechanization enabled a quicker and more efficient production and installation process as roll-formed sheets routinely covered a 3' wide section of the roof with one panel running from eave to ridge.The volume of the steel bar is the product of the area of the cross-section and the length: π x r 2 x l = 3.1416 x 10 2 x 1000 = 314,160 mm 3 = 314.16 cm 3 (r = 1/2 x diameter, . A metal sheet is no different than a rectangular bar, it is in the steel weight calculator for your convenience mostly. The formula used to compute the weight is .Rear Quarter Section Left (Driver) Side 21x15x5 VW Beetle & VW Super Beetle 1952-79. VW Beetle. .00. Add to Cart 33 Part #: 95 10 57 1 Rear Quarter Section . Gas Filler Sheet Metal Fuel Filler Body Section. VW Beetle and VW Super Beetle 1968-79. VW Beetle. .00. Add to Cart Part #: 818-115-0300. Accessories .

passive headphone distribution box

Sigma's weatherproof one-gang boxes provide a junction for conduits and can house a single wired device such as a receptacle or switch. They can also be used to mount lampholders and lighting systems in outdoor applications.

sheet metal sections|sheet metal manufacturing process