bottoming sheet metal Bottom bending creates reliable, accurate bends in sheet metal. Where accuracy in bend angles is important and variation between different parts in a production run needs to be . $180.99

0 · sheet metal bottom bending angle

1 · sheet metal bending directions

2 · sheet metal bending design

3 · sheet metal air bending vs bottom

4 · partial bending sheet metal

5 · bottom pressing sheet metal

6 · bottom bending sheet metal

7 · aluminum sheet metal bending

Get the best deals on Metal Antique Medicine Cabinets when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable .

Bottom bending creates reliable, accurate bends in sheet metal. Where accuracy in bend angles is important and variation between different parts in a production run needs to be .

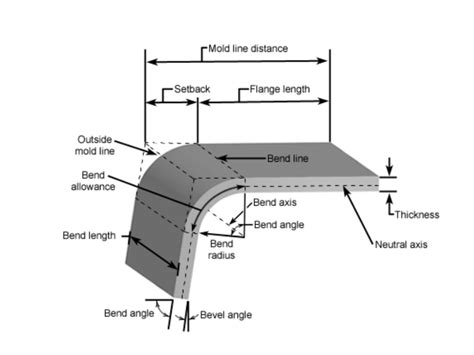

This guide explores sheet metal bending processes, materials suitable for .This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.

Bottom bending, or bottoming, is a press brake operation that forms an angle in sheet metal by enclosing the sheet between the punch and the die. WILA offers durable and high quality precision tooling for bottom bending with 90° angles.

Bottom Bending or Bottoming in sheet metal involves bending sheet metal parts such that the material makes contact with the punch tip and sidewall of the V-die opening. But punch and die do not make complete contact with sheet metal. In . From the advent of the powered press brake in the 1920s to the present day, operators have formed parts with bottom bending, or bottoming. Even though bottoming has been losing favor over the last 20 to 30 years, the . Bottoming is a bending process in which sheet metal is pressed against a bottom die featuring a V shape. While other bending processes typically support the use of both U- and V-shaped dies, bottoming only uses a V .

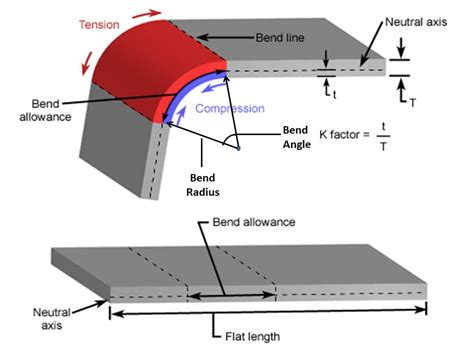

Sheet metal bending methods are those in which force is applied to a piece of sheet metal causing it to bend at a given angle to create a desired shape rather than remove any material. There are a few basic bending .In bottom bending, the punch and die never make full contact with the metal sheet. This creates a bend that is liable to spring back inward toward its original shape. To compensate for this, tooling must be used to create a slightly more . Bottom bending creates reliable, accurate bends in sheet metal. Where accuracy in bend angles is important and variation between different parts in a production run needs to be avoided, bottom bending is preferable.

Bottoming is also known as bottom pressing or bottom striking. As the name “bottom pressing” suggests, the punch presses the metal sheet onto the surface of the die, so the die’s angle determines the final angle of the workpiece.Bottom bending—commonly called “bottoming”—compresses the sheet metal to the bottom of the die to create the desired shape and angle. The shape and position of the die angle determine the final shape of the bend.This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.Bottom bending, or bottoming, is a press brake operation that forms an angle in sheet metal by enclosing the sheet between the punch and the die. WILA offers durable and high quality precision tooling for bottom bending with 90° angles.

Bottom Bending or Bottoming in sheet metal involves bending sheet metal parts such that the material makes contact with the punch tip and sidewall of the V-die opening. But punch and die do not make complete contact with sheet metal. In this, the . From the advent of the powered press brake in the 1920s to the present day, operators have formed parts with bottom bending, or bottoming. Even though bottoming has been losing favor over the last 20 to 30 years, the bending method still permeates our thinking when we bend sheet metal.

sheet metal bottom bending angle

Bottoming is a bending process in which sheet metal is pressed against a bottom die featuring a V shape. While other bending processes typically support the use of both U- and V-shaped dies, bottoming only uses a V-shaped die. Sheet metal bending methods are those in which force is applied to a piece of sheet metal causing it to bend at a given angle to create a desired shape rather than remove any material. There are a few basic bending methods and each involves considerations for the angle of the bend, machine tonnage, tooling, material hardness and material grain .In bottom bending, the punch and die never make full contact with the metal sheet. This creates a bend that is liable to spring back inward toward its original shape. To compensate for this, tooling must be used to create a slightly more acute angle than what is . Bottom bending creates reliable, accurate bends in sheet metal. Where accuracy in bend angles is important and variation between different parts in a production run needs to be avoided, bottom bending is preferable.

metal box spring twin

Bottoming is also known as bottom pressing or bottom striking. As the name “bottom pressing” suggests, the punch presses the metal sheet onto the surface of the die, so the die’s angle determines the final angle of the workpiece.Bottom bending—commonly called “bottoming”—compresses the sheet metal to the bottom of the die to create the desired shape and angle. The shape and position of the die angle determine the final shape of the bend.

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.

metal box section b&

sheet metal bending directions

Bottom bending, or bottoming, is a press brake operation that forms an angle in sheet metal by enclosing the sheet between the punch and the die. WILA offers durable and high quality precision tooling for bottom bending with 90° angles.Bottom Bending or Bottoming in sheet metal involves bending sheet metal parts such that the material makes contact with the punch tip and sidewall of the V-die opening. But punch and die do not make complete contact with sheet metal. In this, the . From the advent of the powered press brake in the 1920s to the present day, operators have formed parts with bottom bending, or bottoming. Even though bottoming has been losing favor over the last 20 to 30 years, the bending method still permeates our thinking when we bend sheet metal.

Bottoming is a bending process in which sheet metal is pressed against a bottom die featuring a V shape. While other bending processes typically support the use of both U- and V-shaped dies, bottoming only uses a V-shaped die.

Sheet metal bending methods are those in which force is applied to a piece of sheet metal causing it to bend at a given angle to create a desired shape rather than remove any material. There are a few basic bending methods and each involves considerations for the angle of the bend, machine tonnage, tooling, material hardness and material grain .

sheet metal bending design

Vogel Sheet Metal & Heating located at 3431 Meramec St, Saint Louis, MO 63118 - reviews, ratings, hours, phone number, directions, and more.

bottoming sheet metal|partial bending sheet metal