cnc machine dimensions In this comprehensive guide, we have explored the key dimensions of CNC machines and their significance in the manufacturing process. Understanding these dimensions is crucial for . My home already had a 3-way switch installed and one of the switches was in the wall with only the 3-wire in place. Generally with 3-way switches, one switch will have the power.

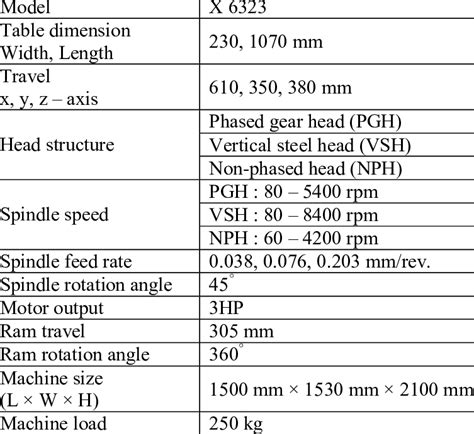

0 · specifications of cnc milling machine

1 · specification of cnc machine

2 · large scale cnc machine

3 · large cnc machine for wood

4 · large cnc cutting machine

5 · cnc machining size consideration

6 · cnc lathe machine specification

7 · best medium size cnc machine

Install the ground wire into a metal junction box. Connecting all the wires leaves you with one loose wire. This wire should be either green or copper-colored. Locate the ground screw inside the junction box, which must be machine threaded and green in color.

In this comprehensive guide, we have explored the key dimensions of CNC machines and their significance in the manufacturing process. Understanding these dimensions is crucial for .In this section, we will provide an overview of CNC machine specifications, explaining their significance in determining the machine's capabilities. We will discuss the primary . This article reviews the CNC machining size limitations, covering major constraints such as the work envelope of CNC (Computer Numerical Control) mills and the diameter limitations of CNC-turned parts.In this comprehensive guide, we will dive into the various CNC machine specifications, what they mean, and how they impact the overall performance of the CNC machine. 1. Size and Weight:\ .

An effective working area of 15.7"x15.7"x3.31" is large enough for most daily CNC projects. It provides a better experience for larger woodworking projects, whether you're a CNC beginner, a hobbyist, or a small business owner looking for .

You will find all the technical specifications for the Tormach PCNC 1100 CNC mill here, including dimensions, weight, control, power, spindle and maintenance capacities.Maximum part size. CNC milling: 400 x 250 x 150 mm (typically) CNC turning: Ø 500 mm x 1000 mm (typically) Very large CNC machines can produce parts with dimensions up to 2000 x 800 x 1000 mm ( 78’’ x 32’’ x 40’’). 5-axis CNC machining systems typically have a smaller build volume.In this comprehensive guide, we have explored the key dimensions of CNC machines and their significance in the manufacturing process. Understanding these dimensions is crucial for selecting the right CNC machine for specific applications, optimizing productivity, and .

In this section, we will provide an overview of CNC machine specifications, explaining their significance in determining the machine's capabilities. We will discuss the primary specifications to consider and their impact on performance. Section 2: .

This article reviews the CNC machining size limitations, covering major constraints such as the work envelope of CNC (Computer Numerical Control) mills and the diameter limitations of CNC-turned parts. In this guide, I recommend best large-format CNC routers, mills, and lathes. I’ll review machines in a variety of different sizes, all the way from 4040 to 4×8 CNCs, and across every price range. 1. Best 4040 CNC: Sainsmart Genmitsu 4040 CNC Router.In this comprehensive guide, we will dive into the various CNC machine specifications, what they mean, and how they impact the overall performance of the CNC machine. 1. Size and Weight:\ Size and weight are important considerations when selecting a CNC machine.An effective working area of 15.7"x15.7"x3.31" is large enough for most daily CNC projects. It provides a better experience for larger woodworking projects, whether you're a CNC beginner, a hobbyist, or a small business owner looking for enterprise quality for commercial purposes, this is an excellent choice.

You will find all the technical specifications for the Tormach PCNC 1100 CNC mill here, including dimensions, weight, control, power, spindle and maintenance capacities.Linear Way VMCs come with large working capacity options of up to 39.4” x 19.7” x 20.5” travels and 43” x 20” table area. The heavy cutting spindle and rigid machine structure enable higher vertical machining efficiency with better finish and longer tool life – resulting in greater productivity and profitability all around. CNC machines like vertical & horizontal milling and lathes can operate on various axes. To create relatively simple parts, traditional 3-axis machines can manipulate parts along three linear axes (X, Y, and Z). The 5-axis machining can work along the three linear axes and around two rotational axes to create more complex components.Maximum part size. CNC milling: 400 x 250 x 150 mm (typically) CNC turning: Ø 500 mm x 1000 mm (typically) Very large CNC machines can produce parts with dimensions up to 2000 x 800 x 1000 mm ( 78’’ x 32’’ x 40’’). 5-axis CNC machining systems typically have a smaller build volume.

In this comprehensive guide, we have explored the key dimensions of CNC machines and their significance in the manufacturing process. Understanding these dimensions is crucial for selecting the right CNC machine for specific applications, optimizing productivity, and .

specifications of cnc milling machine

specification of cnc machine

In this section, we will provide an overview of CNC machine specifications, explaining their significance in determining the machine's capabilities. We will discuss the primary specifications to consider and their impact on performance. Section 2: .

This article reviews the CNC machining size limitations, covering major constraints such as the work envelope of CNC (Computer Numerical Control) mills and the diameter limitations of CNC-turned parts.

In this guide, I recommend best large-format CNC routers, mills, and lathes. I’ll review machines in a variety of different sizes, all the way from 4040 to 4×8 CNCs, and across every price range. 1. Best 4040 CNC: Sainsmart Genmitsu 4040 CNC Router.

In this comprehensive guide, we will dive into the various CNC machine specifications, what they mean, and how they impact the overall performance of the CNC machine. 1. Size and Weight:\ Size and weight are important considerations when selecting a CNC machine.

An effective working area of 15.7"x15.7"x3.31" is large enough for most daily CNC projects. It provides a better experience for larger woodworking projects, whether you're a CNC beginner, a hobbyist, or a small business owner looking for enterprise quality for commercial purposes, this is an excellent choice.You will find all the technical specifications for the Tormach PCNC 1100 CNC mill here, including dimensions, weight, control, power, spindle and maintenance capacities.Linear Way VMCs come with large working capacity options of up to 39.4” x 19.7” x 20.5” travels and 43” x 20” table area. The heavy cutting spindle and rigid machine structure enable higher vertical machining efficiency with better finish and longer tool life – resulting in greater productivity and profitability all around.

large scale cnc machine

large cnc machine for wood

Wiremold 500 Series raceway is ideal for surface mounting small amounts of electrical wiring or communication cables. This rugged raceway offers a low profile appearance which blend with any decor. Available in our exclusive ScuffCoat finish.

cnc machine dimensions|specification of cnc machine