20 ga galvanized sheet metal thickness These are American (Brown & Sharpe) Gauges.

Understand the duties and responsibilities of a CNC machine operator. Acquire the necessary skills, training, and certifications for success in the field. Explore the various career opportunities available for CNC machine operators. Prioritize safety in CNC machine operation to ensure a secure work environment.

0 · steel plate gauge thickness chart

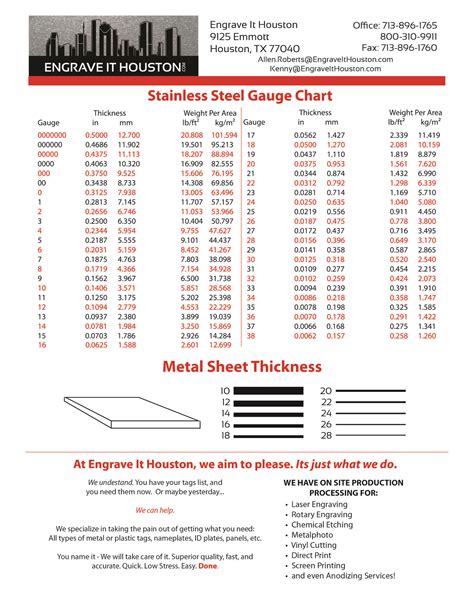

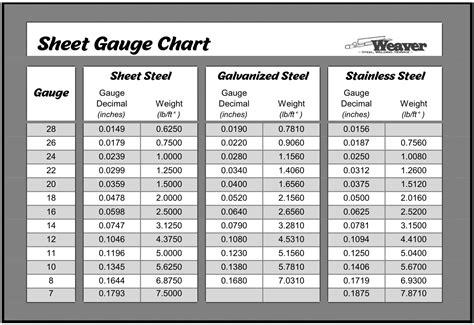

1 · sheet metal gauge chart weight

2 · galvanized steel size chart

3 · galvanized sheet metal gauge chart

4 · galvanized gauge thickness chart

5 · galv sheet metal gauge chart

6 · 22 ga galvanized steel thickness

7 · 16 ga galvanized steel thickness

G90 Galvanized Steel is hot dipped in zinc - coated with a minimum 0.90 oz. of zinc per square foot. This gives the steel excellent corrosion resistance. Suitable for exterior applications.

Ga. is different from inches, there is no conversion formula. Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below.Galvanized Steel Coil & Sheet; Galvalume Steel Coil & Sheet; Corrugated Steel . The chart below can be used to determine the equivalent sheet thickness, in inches .Cold and hot rolled steel: 16 gauge, 14 gauge, 1/8" and 1/4". Copper: 48 oz, 24 oz, 20 oz and 16 oz. Galvanized steel: 24 gauge, 20 gauge, 18 gauge and 16 gauge.

GAUGE TO THICKNESS CHART Gauge Stainless Galvanized Sheet Steel Aluminum Fraction inches (mm) inches (mm) inches (mm) inches (mm) 30 0.0125 (0.33) 0.0157 (0.40) 0.0120 . These are American (Brown & Sharpe) Gauges.Find the proper measurement for your gauge size. This chart compares gage numbers to their steel and aluminum sizing standards.,829.00

,029.009.00† Gauge (also “gage”) thickness in inches (millimeters) is approximate.

Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for .Sheet metal thickness gauges for steel are based on a weight of 41.82 pounds per square foot per inch of thickness. This is known as the Manufacturers’ Standard Gauge for Sheet Steel. For galvanized material, the decimal by .Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect .

Ga. is different from inches, there is no conversion formula. Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below.The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.Cold and hot rolled steel: 16 gauge, 14 gauge, 1/8" and 1/4". Copper: 48 oz, 24 oz, 20 oz and 16 oz. Galvanized steel: 24 gauge, 20 gauge, 18 gauge and 16 gauge.GAUGE TO THICKNESS CHART Gauge Stainless Galvanized Sheet Steel Aluminum Fraction inches (mm) inches (mm) inches (mm) inches (mm) 30 0.0125 (0.33) 0.0157 (0.40) 0.0120 (0.30) 0.0100 (0.25) . 20 0.0375 (0.95) 0.0396 (1.01) 0.0359 (0.91) 0.0320 (0.81)

steel plate gauge thickness chart

These are American (Brown & Sharpe) Gauges.Find the proper measurement for your gauge size. This chart compares gage numbers to their steel and aluminum sizing standards.† Gauge (also “gage”) thickness in inches (millimeters) is approximate.Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for width over 32" to 60" inclusive.

Sheet metal thickness gauges for steel are based on a weight of 41.82 pounds per square foot per inch of thickness. This is known as the Manufacturers’ Standard Gauge for Sheet Steel. For galvanized material, the decimal by gauge and weight per pound is .

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.

Ga. is different from inches, there is no conversion formula. Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below.The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.

Cold and hot rolled steel: 16 gauge, 14 gauge, 1/8" and 1/4". Copper: 48 oz, 24 oz, 20 oz and 16 oz. Galvanized steel: 24 gauge, 20 gauge, 18 gauge and 16 gauge.GAUGE TO THICKNESS CHART Gauge Stainless Galvanized Sheet Steel Aluminum Fraction inches (mm) inches (mm) inches (mm) inches (mm) 30 0.0125 (0.33) 0.0157 (0.40) 0.0120 (0.30) 0.0100 (0.25) . 20 0.0375 (0.95) 0.0396 (1.01) 0.0359 (0.91) 0.0320 (0.81)

These are American (Brown & Sharpe) Gauges.

Find the proper measurement for your gauge size. This chart compares gage numbers to their steel and aluminum sizing standards.

† Gauge (also “gage”) thickness in inches (millimeters) is approximate.Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for width over 32" to 60" inclusive.Sheet metal thickness gauges for steel are based on a weight of 41.82 pounds per square foot per inch of thickness. This is known as the Manufacturers’ Standard Gauge for Sheet Steel. For galvanized material, the decimal by gauge and weight per pound is .

cnc fabrication machines

sheet metal gauge chart weight

The key difference is that the main panel is the breaker box where the electrical power from the electrical company flows through and controls the power supply to the entire building, while a sub-panel installation is a secondary breaker box that distributes power to specific areas or circuits within the building, and has its own breakers.

20 ga galvanized sheet metal thickness|sheet metal gauge chart weight