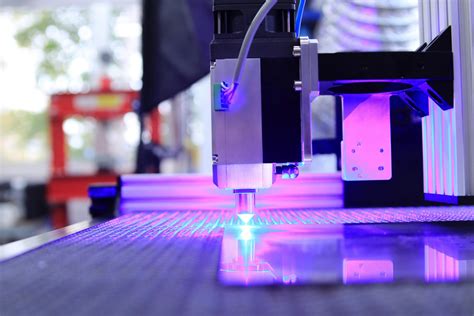

adjust cnc machine motor Calibration involves adjusting the CNC machine to enhance its operational accuracy. It includes documenting the location, updating the software, inputting material measurements, calibrating . Zimtown Large Digital Electronic Safe Box Keypad Lock Security Home Office Hotel Gun Secure By James Joseph Keeping everything important safe

0 · mastering cnc calibration

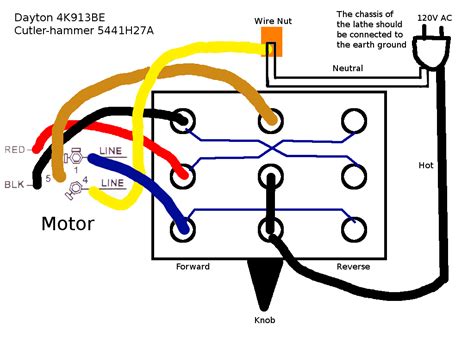

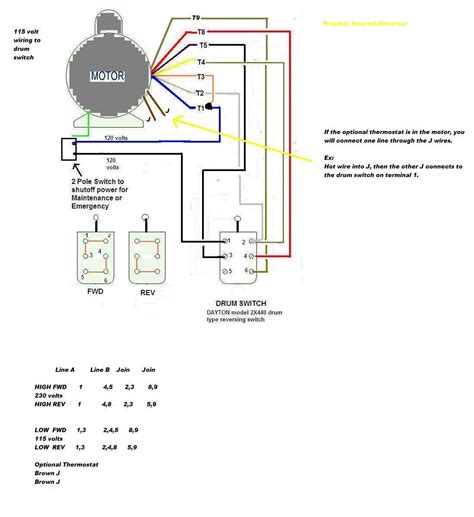

1 · mach4 motor acceleration adjustment

2 · how to reverse machmotion motor

3 · how to reverse mach motor

4 · calibration for cnc machine

Unlike a traditional box spring, this cleverly crafted foundation is made with a thick and sturdy steel frame for ultimate strength and longevity. Build It, Stress-Free. All tools, parts and instructions are conveniently packed into one box for set-up that takes less than an hour with a friend's help. Now that's what we call smart!

How backlash can be corrected with software and hardware. How temperatures, speed and vibration contribute to backlash. A step by step guide on how to change your MachMotion backlash settings. ACCURACY VS. PRECISION? Backlash with a CNC is the same as taking . In this video I go over the pros and cons of changing the motor acceleration settings in Mach4 to reduce vibrations that degrade spindle cut quality and laser line quality. I also cover Constant.Calibration involves adjusting the CNC machine to enhance its operational accuracy. It includes documenting the location, updating the software, inputting material measurements, calibrating . Cincinnati Milacron explains in their manuals how to adjust gibs on a CNC machine by saying that you should tighten the gib until it increases observed backlash, then back off .

Calibrating a CNC (Computer Numerical Control) machine is crucial for achieving accurate and precise results in manufacturing processes. In this blog post, we will guide you through the . Here, we will discuss 5 of the most important faults that will jeopardize your CNC machine accuracy. We will also disclose how to check and improve them to get better precision from your CNC or 3D printer. CNC .

Gib adjustment requires a much tighter table for CNC and rightfully so..this gives superior dimensional control, and rigidity. Motors must be sized not only for cutting loads, but .Fortunately Mach has an automated motor tuning feature that will make this easy. Go to the "SETTINGS" tab and you'll find "Axis Calibration" right over the "RESET" button. Note: You will need either a digital movement gauge or a . Fortunately, Mach has an automated motor tuning feature that will make this easy. Go to the “Settings” tab and you’ll find “Calibrate Motors”. Note: You will need either a digital movement gauge or a tape measure before going .How backlash can be corrected with software and hardware. How temperatures, speed and vibration contribute to backlash. A step by step guide on how to change your MachMotion backlash settings. ACCURACY VS. PRECISION? Backlash with a CNC is the same as taking a screw and threading a nut on to it.

Axis backlash checking and adjustment procedure for CNC. Machine parameter compensation, problems and causes related to excessive mechanical slop in ballscrews and gibs.In this video I go over the pros and cons of changing the motor acceleration settings in Mach4 to reduce vibrations that degrade spindle cut quality and laser line quality. I also cover Constant.Calibration involves adjusting the CNC machine to enhance its operational accuracy. It includes documenting the location, updating the software, inputting material measurements, calibrating the axis, and more. Cincinnati Milacron explains in their manuals how to adjust gibs on a CNC machine by saying that you should tighten the gib until it increases observed backlash, then back off until the increased backlash goes away. I'm experimenting with that right now for the first time on a machine with box ways.

Calibrating a CNC (Computer Numerical Control) machine is crucial for achieving accurate and precise results in manufacturing processes. In this blog post, we will guide you through the process of calibrating a CNC machine to ensure optimal performance.

mastering cnc calibration

mach4 motor acceleration adjustment

Here, we will discuss 5 of the most important faults that will jeopardize your CNC machine accuracy. We will also disclose how to check and improve them to get better precision from your CNC or 3D printer. CNC Accuracy Requires Rigidity Against Bending Forces Gib adjustment requires a much tighter table for CNC and rightfully so..this gives superior dimensional control, and rigidity. Motors must be sized not only for cutting loads, but to handle this "stiff" challange

Fortunately Mach has an automated motor tuning feature that will make this easy. Go to the "SETTINGS" tab and you'll find "Axis Calibration" right over the "RESET" button. Note: You will need either a digital movement gauge or a tape measure before going further.

Fortunately, Mach has an automated motor tuning feature that will make this easy. Go to the “Settings” tab and you’ll find “Calibrate Motors”. Note: You will need either a digital movement gauge or a tape measure before going further. Make sure your Units are set to MM.How backlash can be corrected with software and hardware. How temperatures, speed and vibration contribute to backlash. A step by step guide on how to change your MachMotion backlash settings. ACCURACY VS. PRECISION? Backlash with a CNC is the same as taking a screw and threading a nut on to it.Axis backlash checking and adjustment procedure for CNC. Machine parameter compensation, problems and causes related to excessive mechanical slop in ballscrews and gibs.

In this video I go over the pros and cons of changing the motor acceleration settings in Mach4 to reduce vibrations that degrade spindle cut quality and laser line quality. I also cover Constant.Calibration involves adjusting the CNC machine to enhance its operational accuracy. It includes documenting the location, updating the software, inputting material measurements, calibrating the axis, and more. Cincinnati Milacron explains in their manuals how to adjust gibs on a CNC machine by saying that you should tighten the gib until it increases observed backlash, then back off until the increased backlash goes away. I'm experimenting with that right now for the first time on a machine with box ways.

Calibrating a CNC (Computer Numerical Control) machine is crucial for achieving accurate and precise results in manufacturing processes. In this blog post, we will guide you through the process of calibrating a CNC machine to ensure optimal performance. Here, we will discuss 5 of the most important faults that will jeopardize your CNC machine accuracy. We will also disclose how to check and improve them to get better precision from your CNC or 3D printer. CNC Accuracy Requires Rigidity Against Bending Forces Gib adjustment requires a much tighter table for CNC and rightfully so..this gives superior dimensional control, and rigidity. Motors must be sized not only for cutting loads, but to handle this "stiff" challange

Fortunately Mach has an automated motor tuning feature that will make this easy. Go to the "SETTINGS" tab and you'll find "Axis Calibration" right over the "RESET" button. Note: You will need either a digital movement gauge or a tape measure before going further.

how to reverse machmotion motor

mains junction box splitter

The versatility of zinc sheet makes it ideal for exterior and interior architectural applications. Rotometals' zinc strips for roofs meet all ENG 988 Standards. Zinc's natural self-healing properties provide years of virtually maintenance-free protection for your zinc roofing.

adjust cnc machine motor|how to reverse mach motor