cnc flipping a part OP #1 - set your origin on the part not the rough stock. This requires touching off the stock and then insetting to account for the amount of material you want to remove from x,y and . 2x4 Door Barricade Brackets, Black Iron Metal U Bracket, Heavy Duty Open Bar Security Holder Bracket for Home, Garage, Gate, Barn, Shed(4PCS)

0 · offset in cnc parts

1 · offset for flipping parts

2 · cnc router flip machining

3 · cnc machining practice

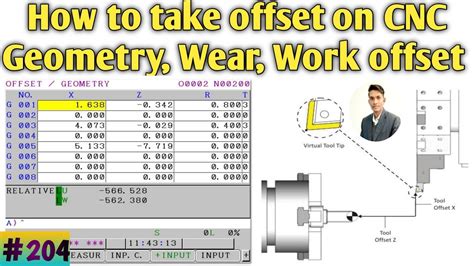

4 · cnc machining offset instructions

A pack of 20 high-quality, 20mm deep, U-way and Y-way electrical junction boxes from Dignity. Key Features: – 20mm depth for comfortable wiring – U-way and Y-way configurations for flexibility – High-quality plastic material for durability – .

offset in cnc parts

cnc machine service engineer

offset for flipping parts

Kevin takes you through the process of designing and executing a two sided part. With several examples of how to workhold the B-Side. .more. The process of making two sided CNC parts can. OP #1 - set your origin on the part not the rough stock. This requires touching off the stock and then insetting to account for the amount of material you want to remove from x,y and . When I put the physical stock in the vise I shunt it up against the stop and touch off the Z height and begin the first op. All seems well at this point, but when I flip the part I .

oday we set up the machine to finish machining the bottom of the part we started in Episode 1! Stay tuned for more CNC related educational videos. Thank you to all of my Patrons and Syil.CNC Machining a Heat Sink on the Tormach 770 using Fusion 360, focusing on three things: Comparing 1/4 and 3/16″ tools in a 2D Adaptive: Which is faster? How to 3D Surface a Fillet with a Bullnose End Mill; How to Flip your Part for . When you are machining both sides of a piece of stock, it's critical to line up the part precisely when flipping it over. If you don't have an elaborate setup, it may be difficult to .

How do you create your X Y Z Zero in Fusion 360 - a.k.a. your Work Coordinate System or WCS when CNC Machining a part? Let's walk through how we did this fo.Kevin takes you through the process of designing and executing a two sided part. With several examples of how to workhold the B-Side. .more. The process of making two sided CNC parts can.

cnc machine sell

What is a CNC flip part? In this article we have explained the various types of flip part angles and their dimensions that help in accurate cnc machining. OP #1 - set your origin on the part not the rough stock. This requires touching off the stock and then insetting to account for the amount of material you want to remove from x,y and z. This will account for varying lengths of rough stock. OP#2 - . When I put the physical stock in the vise I shunt it up against the stop and touch off the Z height and begin the first op. All seems well at this point, but when I flip the part I make sure the newly machined dimensions are now pressed against the stop and in CAM i set the datum off the model edge. oday we set up the machine to finish machining the bottom of the part we started in Episode 1! Stay tuned for more CNC related educational videos. Thank you to all of my Patrons and Syil.

CNC Machining a Heat Sink on the Tormach 770 using Fusion 360, focusing on three things: Comparing 1/4 and 3/16″ tools in a 2D Adaptive: Which is faster? How to 3D Surface a Fillet with a Bullnose End Mill; How to Flip your Part for 2nd and 3rd Operations! When you are machining both sides of a piece of stock, it's critical to line up the part precisely when flipping it over. If you don't have an elaborate setup, it may be difficult to precisely measure the distance to an edge of your material or line up your spindle with an edge of .How do you create your X Y Z Zero in Fusion 360 - a.k.a. your Work Coordinate System or WCS when CNC Machining a part? Let's walk through how we did this fo.

If you flip a part using normal vice without a dedicated fixture setup, then you need to indicate the part really well. If you were say relying on the back face of the jaws to reference, or other index stops, sometimes its not good enough if you clamp hard or you don't put it .

The only real difference is how you need to flip the part. In my work the first side is done under g55 by aligning a machined face with the left corner of the vise. I'll flip the part and align the same face against the right side of the vise where g56 is .

Kevin takes you through the process of designing and executing a two sided part. With several examples of how to workhold the B-Side. .more. The process of making two sided CNC parts can.

What is a CNC flip part? In this article we have explained the various types of flip part angles and their dimensions that help in accurate cnc machining.

OP #1 - set your origin on the part not the rough stock. This requires touching off the stock and then insetting to account for the amount of material you want to remove from x,y and z. This will account for varying lengths of rough stock. OP#2 - . When I put the physical stock in the vise I shunt it up against the stop and touch off the Z height and begin the first op. All seems well at this point, but when I flip the part I make sure the newly machined dimensions are now pressed against the stop and in CAM i set the datum off the model edge. oday we set up the machine to finish machining the bottom of the part we started in Episode 1! Stay tuned for more CNC related educational videos. Thank you to all of my Patrons and Syil.CNC Machining a Heat Sink on the Tormach 770 using Fusion 360, focusing on three things: Comparing 1/4 and 3/16″ tools in a 2D Adaptive: Which is faster? How to 3D Surface a Fillet with a Bullnose End Mill; How to Flip your Part for 2nd and 3rd Operations!

When you are machining both sides of a piece of stock, it's critical to line up the part precisely when flipping it over. If you don't have an elaborate setup, it may be difficult to precisely measure the distance to an edge of your material or line up your spindle with an edge of .

How do you create your X Y Z Zero in Fusion 360 - a.k.a. your Work Coordinate System or WCS when CNC Machining a part? Let's walk through how we did this fo. If you flip a part using normal vice without a dedicated fixture setup, then you need to indicate the part really well. If you were say relying on the back face of the jaws to reference, or other index stops, sometimes its not good enough if you clamp hard or you don't put it .

Box junctions. These have criss-cross yellow lines painted on the road (see ‘Road markings’). You MUST NOT enter the box until your exit road or lane is clear. However, you may enter the.

cnc flipping a part|offset in cnc parts