cnc machine machining operations CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or workpiece, to produce a custom-designed part 1. One of those details is setting the right parameters on your new MIG welder for the job at hand. You are probably here for this reason, so I’ll explain the main MIG settings and how they should be adjusted.

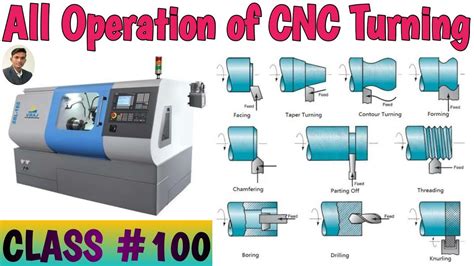

0 · types of cnc operations

1 · different types of cnc machines

2 · cnc machine setup operator

3 · cnc machine operator meaning

4 · cnc machine operations list

5 · cnc machine operation basics

6 · cnc machine operating instructions

7 · cnc machine basic knowledge

This article covers everything you need to know about welding thin sheet metal: from tips for beginners to advanced welding techniques that experienced professionals use under difficult circumstances.Harbor freight 60/120 Amp flux core welder (.030 wire) I spent about 3 hours yesterday blowing holes though the sheet metal. Am I just wasting time here, or is this .

types of cnc operations

fabric metal rings

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or . CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product.CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or workpiece, to produce a custom-designed part 1. Unlock the potential of CNC machinery with our detailed overview of the 11 main types of CNC machine operations and processes. Perfect for enthusiasts and professionals looking to deepen their understanding of CNC technology.

CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

CNC machining is a widely used method for mass producing metal and plastic parts in industries like aerospace. It offers precision and automation, eliminating the risk of human error. CNC machines work by following programmed instructions and can use multiple tools simultaneously. The most common CNC machine language is G-code. CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at .

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process. We’ll also explore the various applications of CNC machining and the future of this field. 1.

CNC machining refers to the manufacturing and processing of parts and products controlled by computers. It involves the use of computer numerical control (CNC) machine tools to automatically remove excess material from a workpiece by processing and adjusting it. CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product.CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or workpiece, to produce a custom-designed part 1.

different types of cnc machines

Unlock the potential of CNC machinery with our detailed overview of the 11 main types of CNC machine operations and processes. Perfect for enthusiasts and professionals looking to deepen their understanding of CNC technology. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to . CNC machining is a widely used method for mass producing metal and plastic parts in industries like aerospace. It offers precision and automation, eliminating the risk of human error. CNC machines work by following programmed instructions and can use multiple tools simultaneously. The most common CNC machine language is G-code. CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material.

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at . CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process. We’ll also explore the various applications of CNC machining and the future of this field. 1.

While these professions share some common ground, they have distinct roles, responsibilities, and areas of specialization. In this article, we’ll delve into the differences between a welder and a metal fabricator to provide a .

cnc machine machining operations|cnc machine operating instructions