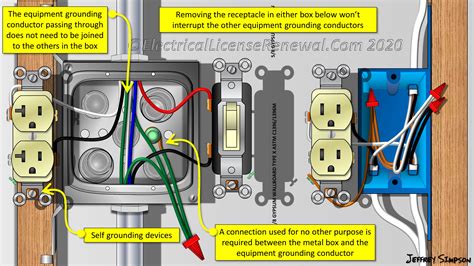

do metal boxes need to be grounded on commercial property (A) allows no bond wire when box is mounted on the surface, and the receptacle has direct metal-to-metal contact between the device yoke and the box shall be permitted to ground the receptacle to the box. We manufacture ASME code closure assemblies (Manways), Hinged Closures, Swing Bolts, Camlock Closures & Access Hatches in sizes 4 inch to 30 inch.

0 · not grounding metal electrical box

1 · nec metal box grounding requirements

2 · nec metal box grounding problems

3 · nec metal box grounding code

4 · metal electrical box grounding

5 · do you need to ground metal boxes

6 · do plastic boxes need grounding

7 · do electrical boxes need grounding

The practical lower metal thickness limitation for flux-cored wire is around 18 GA steel. For autobody sheet metal, the more pratical solution is to use a welder that can use solid wire with C25 shielding gas. The Handler 140 would be a good welder if 115V service is desired. The Handler 187 would be a good solution if 230V service is desired.

not grounding metal electrical box

(A) allows no bond wire when box is mounted on the surface, and the receptacle has direct metal-to-metal contact between the device yoke and the box shall be permitted to ground the receptacle to the box.It is technically acceptable, because the code allows it. This is because due to .

Most regions have strict codes requiring metal buildings to be grounded to improve safety and reduce potential harm to people and property. Start by driving a copper grounding rod, at least .

put metal roof on house

It is technically acceptable, because the code allows it. This is because due to many people believing in myths about grounding, some manufacturers may still tell you to install . To ground a metal electrical box, you will need the following materials: Step 1: Identify the Grounding Lug. The first step is to identify the grounding lug on the metal electrical . The contractor is stating that these metal boxes do not need to be grounded, our inspection team says the code requires them to be grounded, we are certified Md. Inspectors . So while you may not have to connect the equipment grounding conductor to the box, the boxes do have to be grounded and bonded. Since you're using EMT, the boxes can .

Equipment grounding conductors are the effective ground-fault current path at the feeder and branch circuit levels of the premise wiring system, and it must be sized in accordance with Table 250.122, which is based on OCPD size. Metal junction boxes always need to be grounded, whether you're using NM (non-metallic) plastic-sheathed cable or metallic cable. Metallic cable is self-grounding, as long as the cable is properly secured to the box.

You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means . (A) allows no bond wire when box is mounted on the surface, and the receptacle has direct metal-to-metal contact between the device yoke and the box shall be permitted to ground the receptacle to the box.

Most regions have strict codes requiring metal buildings to be grounded to improve safety and reduce potential harm to people and property. Start by driving a copper grounding rod, at least 8 feet in length, into the ground and as close to the building structure as possible. It is technically acceptable, because the code allows it. This is because due to many people believing in myths about grounding, some manufacturers may still tell you to install electrodes to their equipment. So to avoid a conflict with those instructions, the code allows such 'auxiliary' electrodes.Does Every Metal Electrical Box Need to Be Grounded? Grounding a metal electrical box is required by the National Electric Code. Metal is not the kind of material that is going to stop the electricity flow, unlike plastic boxes, for example. To ground a metal electrical box, you will need the following materials: Step 1: Identify the Grounding Lug. The first step is to identify the grounding lug on the metal electrical box. The grounding lug is typically a green or copper-colored screw or bolt.

The contractor is stating that these metal boxes do not need to be grounded, our inspection team says the code requires them to be grounded, we are certified Md. Inspectors at BWI airport and would like your input So while you may not have to connect the equipment grounding conductor to the box, the boxes do have to be grounded and bonded. Since you're using EMT, the boxes can be grounded and bonded via the conduit. If you were using nonmetallic conduit, you'd have to ground the boxes some how.

Equipment grounding conductors are the effective ground-fault current path at the feeder and branch circuit levels of the premise wiring system, and it must be sized in accordance with Table 250.122, which is based on OCPD size.

Metal junction boxes always need to be grounded, whether you're using NM (non-metallic) plastic-sheathed cable or metallic cable. Metallic cable is self-grounding, as long as the cable is properly secured to the box.

You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means exists for replacement switches. (A) allows no bond wire when box is mounted on the surface, and the receptacle has direct metal-to-metal contact between the device yoke and the box shall be permitted to ground the receptacle to the box.Most regions have strict codes requiring metal buildings to be grounded to improve safety and reduce potential harm to people and property. Start by driving a copper grounding rod, at least 8 feet in length, into the ground and as close to the building structure as possible. It is technically acceptable, because the code allows it. This is because due to many people believing in myths about grounding, some manufacturers may still tell you to install electrodes to their equipment. So to avoid a conflict with those instructions, the code allows such 'auxiliary' electrodes.

Does Every Metal Electrical Box Need to Be Grounded? Grounding a metal electrical box is required by the National Electric Code. Metal is not the kind of material that is going to stop the electricity flow, unlike plastic boxes, for example. To ground a metal electrical box, you will need the following materials: Step 1: Identify the Grounding Lug. The first step is to identify the grounding lug on the metal electrical box. The grounding lug is typically a green or copper-colored screw or bolt. The contractor is stating that these metal boxes do not need to be grounded, our inspection team says the code requires them to be grounded, we are certified Md. Inspectors at BWI airport and would like your input

So while you may not have to connect the equipment grounding conductor to the box, the boxes do have to be grounded and bonded. Since you're using EMT, the boxes can be grounded and bonded via the conduit. If you were using nonmetallic conduit, you'd have to ground the boxes some how.Equipment grounding conductors are the effective ground-fault current path at the feeder and branch circuit levels of the premise wiring system, and it must be sized in accordance with Table 250.122, which is based on OCPD size.

Metal junction boxes always need to be grounded, whether you're using NM (non-metallic) plastic-sheathed cable or metallic cable. Metallic cable is self-grounding, as long as the cable is properly secured to the box.

punch down cat6 for telephones at junction box

Here we explain how to check voltage, current, resistance to help diagnose well pump problems such as tripping breakers, blown fuses, weak pump performance or no water .

do metal boxes need to be grounded on commercial property|do electrical boxes need grounding