welding sheet metal to thick steel Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See more We have small, mid sized and large cnc milling and turning services available to service all of our customers requirements. Heavy parts require a large machining envelope and are often awkward for fixturing.

0 · welding thin steel to thick

1 · welding thin metal to thick metal

2 · welding sheet metal

3 · welding aluminum sheet metal

4 · thick metal welding

5 · sheet metal welding process

6 · how to weld thin sheet metal

7 · how to weld sheet metal

There are seven main w holesale CNC precision milling parts: the column, knee, saddle, table, ram, head, and any parts that go with them. For metals that cannot be machined using a drill press or lathe, CNC mills are also used for polishing and grinding.

Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See moreNow that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See moreWelding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more To weld sheet metal with solid wires, use electrode positive (EP, or reverse polarity). Don’t attempt to weld thin materials like sheet metal with flux-cored wires, which put .

MIG Welding Basics: Andy Fogarty demonstrates how to weld thin metal to thick. Shop all welding supplies and metals at www.kingmetals.com today! Don't forget.There needs to be enough metal deposited to actually fill the hole that’s forming. Otherwise, you can also pause a TIG weld and readjust the settings. For more on how to fix holes in your weld, check out our post on it here. That’s all there is .

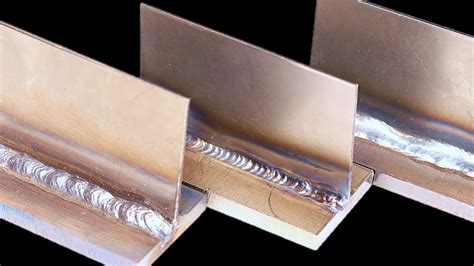

Fuse the thick side without burning through the thin using these techniques for Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW) or Shielded Metal Arc Welding (SMAW). To weld thin metal, choose an appropriate process (TIG or MIG with low amperage), use a smaller diameter wire or filler rod, and adjust travel speed to prevent burn-through. Employ a pulsing technique, stitch welding, or . Thin to thick, here's the trick!Learn faster with an online welding course: https://courses.timwelds.comOther Helpful Videos: MIG Welding Settings: https://y.

As a rule, when MIG welding sheet metal, never use a body filler metal that is thicker than the base metal. It is recommended that a welder should use .023- or .024-inch wire for light gauge sheet metal work. Welding a thin material like sheet metal to thicker metal surfaces can be somewhat of a headache, especially without taking the right approach to welding sheet metal. Below, .

Sheet metal thickness suitable for welding typically ranges up to 1/4 inch using MIG or TIG welding, with TIG preferred for finer work on thinner metals. Which welding is best for thick metal? Stick welding or Flux-Cored Arc . Imagine a welding process that minimizes distortion, enhances precision, and improves efficiency. Laser welding technology for sheet metal does exactly that, revolutionizing industries from automotive to high-tech .Stick Welding Medium-Thickness Metal Stick welding is one of the best, moderately straightforward, and cheapest methods to weld medium-thickness mild steel. These applications usually include on-field repairs, maintenance, .

Metal inert gas (MIG) welding is an arc welding method typically used on large parts m a d e of thick material, such as structural steel parts. With this method, we feed a continuous solid wire electrode through a we lding gun .There is no hard and fast rule with the thickness under which you shouldn’t use stick welding.But there is a fair idea of what constitutes a thin metal and below which using stick welding might become difficult. A lot of people consider anything less than 3/16” to be thin so below this thickness stick welding can start creating problems or can become difficult to handle. Fuse the thick side without burning through the thin using these techniques for Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW) or Shielded Met.

This series includes MIG-230MINI, MIG-230, MIG-280, MIG-280PLUS, MIG-350, MIG-350W, MIG-500, and MIG-500W to fit all your demands of welding either on daily metal fabrication or heavy-industry application. The MIG-230MINI/230 and MIG-280/280PLUS can weld the Aluminum sheet at a thickness of 0.35mm. MIG welding sheet metal requires precision and the right tools. Here’s a streamlined approach, complete with examples, to help you achieve perfect welds on thin metals.. 1. Choosing the Right MIG Welder for Thin Metal: Ideal Specs: A 140 amp, 110V welder works well for metals up to 1/8".; Advanced Feature: Consider a welder with a 3 in 1 No Gas Mig . Can You Weld 22-Gauge Sheet Metal? You can weld a 22-gauge (0.03-inches) metal sheet using a TIG welder or even with a MIG welding unit. However, it is not recommended to stick weld 22-gauge sheet metal as excessive penetration is highly likely to occur and become problematic. The 16 gauge or 1.5mm is a safe bottom limit for material thickness . Hello All, I'm working on 18 ga. sheet metal project where a stamped recess in the sheet metal has become distorted and flattened (no recess). I would like to know how I can restore the recess back into the sheet metal. The recess dimensions are approximately 1 .

Most of the light gauge sheet metal work will require the use of .023- or .24- inch while if you have a sheet metal having a gauge of more than 18-gauge then a .030-inch wire would be the most ideal. A ER70S-6 wire would be most ideal for welding mild steel.

Induction welding; Welding Sheet Metal. For welding purposes, the term “sheet metal” is restricted to thicknesses of metals up to and including 1/8 in. (3.2 mm). Welds in sheet metal up to 1/16 in. (1.6 mm) thick can be made satisfactorily by flanging the edges at the joint. The flanges must be at least equal to the thickness of the metal.Q: How thick can the sheet metal be for wire feed welding? A: Wire feed welding is most effective on metal ranging from thin gauge up to about 1/4 inch thick. For thicker materials, other welding methods might be more suitable. Q: Is it necessary to clean the metal before welding?

The Hobart Handler 140 is an excellent choice for sheet metal welding due to its versatility and user-friendliness. With an amperage range of 25 to 140A, it’s capable of handling various thin materials, including sheet metal. . Whether you’re welding thin carbon steel or folding sheet metal into intricate shapes, it’s essential to .When MIG welding sheet metal, you can opt to leave a small gap or overlap two ends of a sheet. . Welder For Medium-thickness Steel. To weld medium-thickness metal up to 1/2" or 1/4", you will need a 200-250 amp rated welder with 220V input. These machines have enough power to join thicker metal with ease and our recommendation is YesWelder . This welding approach is perfect for welding metals with a thickness of more than six millimeters. Nonetheless, before you use it to weld slimmer metal sheets, you need to adjust the TIG machine to the ideal settings. .

welding thin steel to thick

Now that you have adjusted the MIG welding settings, let’s move on to the techniques for welding thick steel. Techniques for welding thick steel. When welding thick steel, it’s important to use the right techniques to ensure . Recommended Tungsten Option For Mild Steel. When welding mild steel sheet metal, . It is crucial to select the correct tungsten size for the specific thickness of the sheet metal being welded to ensure optimal weld quality and .This gauge is used for measuring the thickness of sheet metal and wire - a must-have for all welders! Order yours online at PrimeWeld. FREE SHIPPING ON ORDERS OVER 0* Contact . Wire & Sheet Metal Thickness Gauge for Welding View image 1; View image 2 This gauge is used for measuring the thickness of sheet metal and wire - a must-have for .

Use thin wire-One big mistake we see with beginners is using welding wire that is too thick for the metal they’re welding. If your welding wire is too thick it will take more heat to melt the wire than the substrate and can make it even more prone to blowing holes in the panel. For thinner gauge sheet metal like 18 or 20 gauge we suggest .023 .

How to Weld Thick to Thin Metal with Gasless Flux Core Wire - Trying out some TIps and Tricks for welding thick to thin metal with gasless flux core wire usi. This guide explains some of the ways to help get the best results when welding thin sheet metal. . Never use a rod that is thicker than the thickness of the metal. Smaller electrodes perform better at lower amperage and will help prevent burn-through. . Copper melts at a much higher temperature than steel so the weld won’t stick to the . In this video I'm showing you a little technique I've learned for welding thicker steel to sheet metal.I use this technique a lot when doing fabrication wor. MIG Welding Basics: Andy Fogarty demonstrates how to weld thin metal to thick. Shop all welding supplies and metals at www.kingmetals.com today! Don't forget.

how do you go about welding thick metal say 2/3mm to 1mm sheet with out blowing holes through the sheet, thanks for help i dont wana sound thick but say your overlap welding 1mm sheet to 1mm sheet, like a car floor etc, does that make you weld a 2mm weld, or are you still welding a 1mm weld, as my chassis is 2mm thick and im plating it up with . The surface of a welding table is usually made of steel plate which can range in thickness from 1/4 inch to 1 inch or more. The thickness of the plate will depend on the intensity of use and type of welding that will be done on it. The thicker the base metal, the larger the welding rod diameter and the amperage. The larger the rod in relation to the thickness of the metal will cause a higher deposition rate and faster welding. If you select a welding rod with the same diameter as the metal thickness, this can cause too much heat and result in warping and blow-through.MIG Welding Sheet Metal. Gas metal arc welding (GMAW or MIG) can be successfully used to weld thin metal, but as long as you take extra care. The heat input is the main issue with sheet metal of 24 gauge up to 14 ga. Thin metal is not so forgiving, so even the slightest heat over the recommended can cause distortion, wrapping, or burn-through.

sheet metal workers local 104 wages

sheet metal workers local 100 health fund

Discover our extensive range of affordable aftermarket CNC replacement parts, designed to keep your machines operating at peak performance. Our high-quality components ensure reliability and longevity, offering a cost-effective alternative to OEM parts.

welding sheet metal to thick steel|how to weld sheet metal