cnc machine laser cutter tolerances Understanding laser cut tolerances (the allowable variation in cut dimensions) is crucial for anyone working with laser-cut materials, from plastics and acrylic to metals and alloys. Laser . CNC machines have revolutionized modern manufacturing by providing a reliable, accurate, and efficient method of producing parts. Whether you’re building components for an .

0 · step by laser cutting

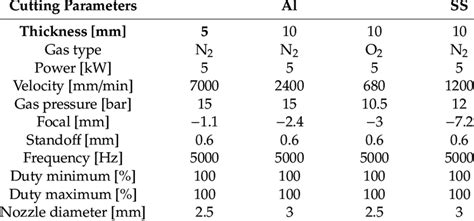

1 · laser cutting parameters stainless steel

2 · laser cutting parameters chart

3 · laser cutting minimum hole size

4 · laser cut tolerances steel plate

5 · laser cut quality chart

6 · how accurate is laser cutting

7 · fiber laser cutting parameters chart

There is a power distribution setup on top of the battery, the likes of which I have never seen before. There is a plate-type buss that has a number of fuses attached to it. None appear to be replaceable and it appears you would have to replace the entire assembly.

Laser cutting tolerance can vary depending on several factors, including the type of machine used, the nature of the material being cut, the thickness of the material, and the quality of the laser beam. Here is a general guideline for laser cutting tolerances.

cnc busbar machine quotes

Laser-cutting tolerance is the most variation allowed between a cut part’s measurements and the original design. It impacts how precise the part is and plays a crucial role in figuring out if it will fit with other parts.Understanding laser cut tolerances (the allowable variation in cut dimensions) is crucial for anyone working with laser-cut materials, from plastics and acrylic to metals and alloys. Laser .In the laser precision cutting world, tight tolerance is defined as the acceptable amount of variation when a part is being processed. Designs that call for precise dimensions require a machining process that can rise to the demands.

step by laser cutting

Tolerances for Laser Cutting Drilling Metals Maintain tolerances to ensure proper performance and avoid rework. Accumet is able to process a vast array of different materials including both .Laser-cutting machines can typically achieve tight tolerances within ±0.1 mm (0.004 inches) or less. This means that the actual size of the cut usually deviates from the expected size by no more than 0.1 mm in either direction.

Laser cutting accuracy depends on several factors, including the type of laser, the power of the laser, and the material being cut. Cutting tolerances are typically within ±0.005 inches, ensuring high precision in manufacturing applications. . The types of tolerances that come into play when cutting with a laser are critical clearance, developmental tolerance, flatness, deviation, maximum depth, minimum width and diameter, corner rounding, and amplitude.Generally, a laser can hold cut part dimensional tolerances of under 0.01" (0.25 mm).* Plasma on the other hand, uses a gas energized to the point of ionization to create a super concentrated . Laser cutting tolerance can vary depending on several factors, including the type of machine used, the nature of the material being cut, the thickness of the material, and the quality of the laser beam. Here is a general guideline for laser cutting tolerances.

laser cutting parameters stainless steel

laser cutting parameters chart

What Are the Standard Laser Cutting Tolerances? Standard laser cutting tolerances typically range within fractions of a millimeter, often around 0.1 mm to 0.5 mm, depending on the material and machine capabilities.

Laser-cutting tolerance is the most variation allowed between a cut part’s measurements and the original design. It impacts how precise the part is and plays a crucial role in figuring out if it will fit with other parts.

Understanding laser cut tolerances (the allowable variation in cut dimensions) is crucial for anyone working with laser-cut materials, from plastics and acrylic to metals and alloys. Laser cutting is known for its exceptional accuracy, delivering tight laser cut hole tolerance with minimal deviation from the desired dimensions, or very tight .

In the laser precision cutting world, tight tolerance is defined as the acceptable amount of variation when a part is being processed. Designs that call for precise dimensions require a machining process that can rise to the demands.Tolerances for Laser Cutting Drilling Metals Maintain tolerances to ensure proper performance and avoid rework. Accumet is able to process a vast array of different materials including both ferrous and non-ferrous metals. This is because of the various laser systems housed within Accumet’s two production facilities.Laser-cutting machines can typically achieve tight tolerances within ±0.1 mm (0.004 inches) or less. This means that the actual size of the cut usually deviates from the expected size by no more than 0.1 mm in either direction.Laser cutting accuracy depends on several factors, including the type of laser, the power of the laser, and the material being cut. Cutting tolerances are typically within ±0.005 inches, ensuring high precision in manufacturing applications. How Accurate is Laser Cutting?

The types of tolerances that come into play when cutting with a laser are critical clearance, developmental tolerance, flatness, deviation, maximum depth, minimum width and diameter, corner rounding, and amplitude.Generally, a laser can hold cut part dimensional tolerances of under 0.01" (0.25 mm).* Plasma on the other hand, uses a gas energized to the point of ionization to create a super concentrated arc that focusses energy at an extraordinarily high temperature.

Laser cutting tolerance can vary depending on several factors, including the type of machine used, the nature of the material being cut, the thickness of the material, and the quality of the laser beam. Here is a general guideline for laser cutting tolerances.What Are the Standard Laser Cutting Tolerances? Standard laser cutting tolerances typically range within fractions of a millimeter, often around 0.1 mm to 0.5 mm, depending on the material and machine capabilities.

Laser-cutting tolerance is the most variation allowed between a cut part’s measurements and the original design. It impacts how precise the part is and plays a crucial role in figuring out if it will fit with other parts.Understanding laser cut tolerances (the allowable variation in cut dimensions) is crucial for anyone working with laser-cut materials, from plastics and acrylic to metals and alloys. Laser cutting is known for its exceptional accuracy, delivering tight laser cut hole tolerance with minimal deviation from the desired dimensions, or very tight .In the laser precision cutting world, tight tolerance is defined as the acceptable amount of variation when a part is being processed. Designs that call for precise dimensions require a machining process that can rise to the demands.

Tolerances for Laser Cutting Drilling Metals Maintain tolerances to ensure proper performance and avoid rework. Accumet is able to process a vast array of different materials including both ferrous and non-ferrous metals. This is because of the various laser systems housed within Accumet’s two production facilities.

laser cutting minimum hole size

Laser-cutting machines can typically achieve tight tolerances within ±0.1 mm (0.004 inches) or less. This means that the actual size of the cut usually deviates from the expected size by no more than 0.1 mm in either direction.Laser cutting accuracy depends on several factors, including the type of laser, the power of the laser, and the material being cut. Cutting tolerances are typically within ±0.005 inches, ensuring high precision in manufacturing applications. How Accurate is Laser Cutting? The types of tolerances that come into play when cutting with a laser are critical clearance, developmental tolerance, flatness, deviation, maximum depth, minimum width and diameter, corner rounding, and amplitude.

laser cut tolerances steel plate

Below is the list of G-codes that are used in most modern CNC Milling machines: Two G-codes may be used in the same block (line), such as G00 and G90, if you want to Rapid to a position in the Absolute mode. Not all of the listed G-codes are applicable to every CNC machine, so please refer your machine’s manual for confirmation.

cnc machine laser cutter tolerances|how accurate is laser cutting