can cnc machines cut miter joints The optimum method for V-grooving with a CNC machine is to use a single sided right angle aggregate head with a V-grooving cutterhead. We (Benz Inc.) can offer you a specially .

It is the control center that commands various components in the power supply line to distribute electric energy reasonably. It is the control link that reliably accepts the upper end power supply and correctly feeds out load electric energy. It is also the key to obtain the user's satisfaction with the quality of power supply.A distribution box ensures that electrical supply is distributed in the building, also known as a distribution board, panel board, breaker panel, or electric panel. It is the central electrical supply system of any building or property.

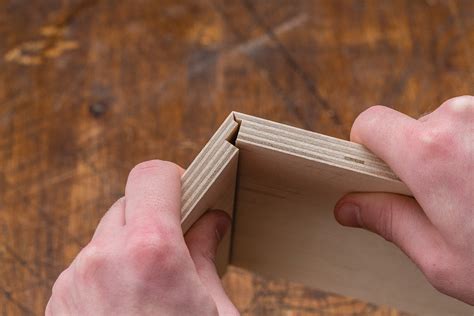

0 · miter fold joints

1 · miter fold cnc

2 · cutting miters on cnc

3 · cnc router cutting miters

Encoders for CNC Machining. CNC machines must maintain position in the face of heavy workpieces and spindles, multi-axis movement and high speeds. Encoders play a huge role in all of the components working together to mill, drill and bore correct parts. We also develop a full line of popular control systems and touch probes used to program CNC .

I have worked with a couple of my clients to get them up and running using CNC's for miterfolding. Ideally, use a 91 degree bit, not a 90. The gap allows for glue without opening the tip of the miter. Taping the joint after milling is fine, and can allow for far better yields in many cases.The optimum method for V-grooving with a CNC machine is to use a single sided . You can make 45 degree cuts several ways using using a CNC. Some depend on how configurable your CNC bed is. For example I can clamp boards at 45 degrees inside my . I'm working on a project that was initially going to use a Miter Fold joint but I can't get the Birch Plywood to cooperate so I've decided to use my Lock Miter bit instead. I was .

Some joints can be cut exclusively on your CNC router while some are made with a little help from a palm router, here are a few example to help get you started: Joints cut only with a CNC router: • Tongue and groove - an easy .The optimum method for V-grooving with a CNC machine is to use a single sided right angle aggregate head with a V-grooving cutterhead. We (Benz Inc.) can offer you a specially .

I select the edge where I want the miter and create a line offset from it inwards by the thickness of the material, or the desired depth of the miter. I use this line as the rail in the “Chamfer” toolpath. With a 90-degree V-bit, this .Save yourself the hassle, unless you are producing many of the same kind of box the best thing is to mount the lock bit in a router table. That way you can test the cut and joint on scrap wood .

metal folding christmas house scene white

The joint was fairly invisible in MDF, so I traced it with pencil so you could see it. Rockler has a tablesaw dado set that will make a similar joint, but, the setup uses shims and blade height adjustments to get the fitment right. You can't do a true miter-fold in solid surface, you need to leave space for glue so the tooling needs to be adjusted so all the glue doesn't squeeze out. You can also go the . Just cut the plywood pieces at the standard 90° to the length of the outside of the miters on each piece. Cut a straight piece of plywood at least 3" wide and as long as your .I have worked with a couple of my clients to get them up and running using CNC's for miterfolding. Ideally, use a 91 degree bit, not a 90. The gap allows for glue without opening the tip of the miter. Taping the joint after milling is fine, and can allow for far better yields in many cases.

You can make 45 degree cuts several ways using using a CNC. Some depend on how configurable your CNC bed is. For example I can clamp boards at 45 degrees inside my CNC frame and use a simple end mill to mill off the end at 45 degrees relative to the board. I want to miter join 12mm plywood using a stronger stepped miter instead of a smooth miter. I realize the tip of the miter will still not come to a perfect point, but have a thin side edge of the opposite board. Or, you can do miter-fold joints on your CNC. The basic idea is that you cut almost, but not quite all the way through the material with a large V-bit, cut out the outline of the part, then lay down a bead of glue and fold the joint. I'm working on a project that was initially going to use a Miter Fold joint but I can't get the Birch Plywood to cooperate so I've decided to use my Lock Miter bit instead. I was thinking of cutting the parts out of flat stock then making a 3/4" MDF jig to hold the pieces up off the table using toggle clamps and dowels to hold the pieces while .

Some joints can be cut exclusively on your CNC router while some are made with a little help from a palm router, here are a few example to help get you started: Joints cut only with a CNC router: • Tongue and groove - an easy to make joint with many applications.

The optimum method for V-grooving with a CNC machine is to use a single sided right angle aggregate head with a V-grooving cutterhead. We (Benz Inc.) can offer you a specially designed head which is equipped with a gear reduction system.

I select the edge where I want the miter and create a line offset from it inwards by the thickness of the material, or the desired depth of the miter. I use this line as the rail in the “Chamfer” toolpath. With a 90-degree V-bit, this quickly produces the desired cut. Here’s a couple of simulated pictures. Save yourself the hassle, unless you are producing many of the same kind of box the best thing is to mount the lock bit in a router table. That way you can test the cut and joint on scrap wood before committing to the final job. The joint was fairly invisible in MDF, so I traced it with pencil so you could see it. Rockler has a tablesaw dado set that will make a similar joint, but, the setup uses shims and blade height adjustments to get the fitment right.I have worked with a couple of my clients to get them up and running using CNC's for miterfolding. Ideally, use a 91 degree bit, not a 90. The gap allows for glue without opening the tip of the miter. Taping the joint after milling is fine, and can allow for far better yields in many cases.

You can make 45 degree cuts several ways using using a CNC. Some depend on how configurable your CNC bed is. For example I can clamp boards at 45 degrees inside my CNC frame and use a simple end mill to mill off the end at 45 degrees relative to the board.

I want to miter join 12mm plywood using a stronger stepped miter instead of a smooth miter. I realize the tip of the miter will still not come to a perfect point, but have a thin side edge of the opposite board. Or, you can do miter-fold joints on your CNC. The basic idea is that you cut almost, but not quite all the way through the material with a large V-bit, cut out the outline of the part, then lay down a bead of glue and fold the joint. I'm working on a project that was initially going to use a Miter Fold joint but I can't get the Birch Plywood to cooperate so I've decided to use my Lock Miter bit instead. I was thinking of cutting the parts out of flat stock then making a 3/4" MDF jig to hold the pieces up off the table using toggle clamps and dowels to hold the pieces while .

Some joints can be cut exclusively on your CNC router while some are made with a little help from a palm router, here are a few example to help get you started: Joints cut only with a CNC router: • Tongue and groove - an easy to make joint with many applications.

The optimum method for V-grooving with a CNC machine is to use a single sided right angle aggregate head with a V-grooving cutterhead. We (Benz Inc.) can offer you a specially designed head which is equipped with a gear reduction system. I select the edge where I want the miter and create a line offset from it inwards by the thickness of the material, or the desired depth of the miter. I use this line as the rail in the “Chamfer” toolpath. With a 90-degree V-bit, this quickly produces the desired cut. Here’s a couple of simulated pictures.

Save yourself the hassle, unless you are producing many of the same kind of box the best thing is to mount the lock bit in a router table. That way you can test the cut and joint on scrap wood before committing to the final job.

miter fold joints

Cable Junction Box. It is designed for cable connections and wire splicing. It is suitable for residential and smaller-scale electrical installations where cables are used instead of conduits.

can cnc machines cut miter joints|miter fold joints