sheet metal mechanical engineering A Whole Suite of Sheet Metal Tools. contains around twenty specialist tools that allow the creation of brackets, sheet metal enclosures and many other Sheet Metal parts. . Internships in Mechanical Engineering: Best 100 companies Is Energy a Good Career Path in 2024? 25 Best Paying Jobs in Energy LOD Definition: Best 10 Point Guide

A bracket is any type of support hardware, usually metal and attached to a wall, used to hold, attach, mount, or secure. This makes bracket hardware especially useful in awning and shade applications.

0 · types of sheet metal materials

1 · sheet metal manufacturing near me

2 · sheet metal fabricators near me

3 · fabricated sheet metal

4 · different types of sheet metals

5 · design for manufacturing sheet metal

6 · custom sheet metal fabricators

7 · basics in sheet metal design

Types of Electrical Boxes 1. Junction Boxes. These boxes connect multiple wires and can serve as a point where circuits split or connect. They are essential for safe electrical installations, especially in complicated wiring systems. 2. Outlet Boxes. Designed to hold electrical outlets, these boxes are typically installed in walls to provide .

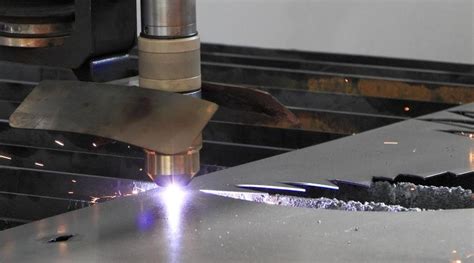

Sheet metal forming is a manufacturing process that uses various techniques to shape thin metal sheets into desired parts. There are a large variety of processes with subtle differences that .Guidelines to be followed when designing for sheet metal. Understand the principles at play behind the factors considered in design. How Material properties affect the Part quality and .

Mechanical engineering general discussion . Regarding minimum sheet metal thickness for tapping 2. Thread starter kar0; Start date Nov 1, 2016; Status Not open for further replies. . The sheet metal has to butt against the flat surface of rear side of Force gaug. From behind the rear of the bracket, the screws (he force gauge manufacturer has . This is a great 9 page PDF entitled "BendWorks: the fine art of Sheet Metal Bending". This is a basic guide to the main processes involved in sheet metal. . AI in Mechanical Engineering. 3 Best Ways How Engineers Can Benefit from ChatGPT. The Ultimate SOLIDWORKS Price Guide – All Options! Wooden 3D Puzzles: Designed, Engineered and .SME Mechanical is a full service mechanical contractor company in central Iowa specializing in complete mechanical design and engineering of heating, ventilation, air-conditioning systems, and piping. Our full service sheet metal .

A Whole Suite of Sheet Metal Tools. contains around twenty specialist tools that allow the creation of brackets, sheet metal enclosures and many other Sheet Metal parts. . Internships in Mechanical Engineering: Best 100 companies Is Energy a Good Career Path in 2024? 25 Best Paying Jobs in Energy LOD Definition: Best 10 Point GuideMechanical Engineering Professionals, LLC has extensive experience in sheet metal design. Whether it is a simple cover or complex fold up for internal structure, we have the design experience to bring your sheet metal product to life.

3,510 Sheet Metal Design Engineer jobs available on Indeed.com. Apply to Design Engineer, Sheet Metal Mechanic, Manufacturing Engineer and more! Skip to main content. Home. Company reviews. Find salaries. Sign in. Sign in. Employers / Post Job. . BAM Mechanical Corp. Mamaroneck, NY 10543. - an hour. Full-time.

Stay updated on the latest advancements in sheet metal engineering and technology. Sheet Metal Engineer Qualifications & Skills Bachelor’s degree in Mechanical Engineering or a related field. Experience with CAD software and engineering design . Mechanical engineering general discussion . Piercing Sheet Metal Formula Thread starter richg1; Start date Oct 15, 2004; Status Not open for further replies. . For example if you used a conical point and had the sheet metal placed over a pipe (or formed surface) with id approximately equal to size of hole you want to make? .I am new to sheet metal design and am learning about it through reading and videos. I have read that if a sheet is to be formed by use of a die, its formability must be analyzed using a Forming Limit Diagram. The literature said manufacturer’s usually provide this data. . Related Engineering Mechanical engineering Sciences Engineering .

Mechanical engineering general discussion . Sheet Metal Fabrication Techniques 8. Thread starter Dinga17; Start date Sep 22, 2018; Status Not open for further replies. . As far as forming the piece. A three roll sheet metal roller will only give you a rough approximation requiring a lot of hand work.

The "Sheet Metal Mechanical Engineering Questions" guide is a valuable resource for all aspiring students preparing for the Mechanical Engineering exam. It focuses on providing a wide range of practice questions to help students gauge their understanding of the exam topics. These questions cover the entire syllabus, ensuring comprehensive .Find your ideal job at Jobstreet with 97 Sheet Metal Mechanical Engineer jobs found in Singapore. View all our Sheet Metal Mechanical Engineer vacancies now with new jobs added daily!sheet metal | Mechanical Engineering Workshop Mechanical engineering general discussion . Sheet Metal Screws 3. Thread starter BoltNutWasher . The most common ones for sheet metal require a punched round hole and a nearby edge or rectangular hole for application of the .

What is the application of a press tool in sheet-metal? Press tools are used in hydraulic, pneumatic & mechanical presses to produce stamped sheet-metal parts. Press tools can be classified based on operation: blanking, piercing, .

Sheet metal Applications. This metal form is used in the automobile industry. It is used to build bodies for aeroplanes, cars, boats, and ships. Iron sheet metals are also used in the energy industry in the making of transformers and other .KHI Mechanical has trained sheet metal workers for custom designed systems to any standard, commercial or industrial applications. We have design build and engineering capabilities for all categories of HVAC and plumbing projects.Find top Sheet Metal Engineer work opportunities in Egypt. Launch your career with our expert recruitment services. Explore new jobs and kickstart your job search today.

Mechanical engineering general discussion . Strengthening Sheetmetal Thread starter TheReg; Start date Aug 1, 2007; Status Not open for further replies. . Any form in the sheet metal will make it stronger, as well as ribs consider dimples in the local area. Also instead of welding brackets have you considered plunging holes for the self .

Trying M5 screws, I discovered that tapping 0.06" aluminum sheet produces very fragile thread, which is easy to strip. Using #10 sheet metal screws with predrilled hole produced better strength, but still possible to strip with a screwdriver. What is the optimum screw size and a thread pitch to use on 0.06" aluminum sheet?

Mechanical Engineer Yaskawa Electric America "It's got to be 5pm somewhere!" RE: SHEET METAL jistre (Mechanical) 29 Nov 07 16:21. Agreed. Never provide a flat pattern to a fabricator. You have sheet metal formulae that will give you things like bend radius that are used to generate the patterns, but they're worthless. . Fred that is the sort of thing we design all the time and yes it is possible to manufacture as two halves and weld them together. Basically you would need to draw the shells and the trim around the edges and then wipe the rest of the sides down and finally cam trim the open edge, it is possible that you could lose the cam trim edge and work to a development but . Mechanical engineering general discussion . Sheet Metal Bending 3. Thread starter sbozy25; Start date Nov 26, 2007; Status Not open for further replies. . It's always good to check with your sheet metal fabricator to see what bend radius they can provide, in addition to knowing what your requirements are. .

See attached image of a typical sheet metal box. 2mm thick and seal welded in all 4 corners. There is only 1mm space to the outside of each face. Now the problematic area. The top 4 edges. These are edges of 2mm sheet. Imagine this has a hinged lid which can swing open and then lock shut using a latch of some sort. In today’s evolving engineering landscape, AutoCAD Mechanical has become a go-to tool for sheet metal design, providing a suite of powerful features that enhance productivity and precision.This blog will walk through the latest tools and features in AutoCAD Mechanical that streamline sheet metal design, offering engineers greater flexibility, efficiency, and accuracy.14 Sheet Metal Mechanical Engineer jobs available on Indeed.com. Apply to Metallurgical Engineer, Mechanic, Construction Project Engineer and more!

Mechanical engineering general discussion . Clinch nuts vs tapped extrusions sheet metal 1 . Our own prototype sheet metal shop had no particular difficulty doing the extruding, given a reasonable tolerance and a few test articles. Express tapping goes really quick, especially if you have an auto-reversing tapping head. .

types of sheet metal materials

sheet metal work definition

sheet metal window sill

Several factors can influence the quality and efficiency of the sheet metal punching process. These include the type and thickness of the material being punched, the size and shape of the punch and die, the alignment of the punch and die, the force applied to the punch, and the speed of the operation.

sheet metal mechanical engineering|design for manufacturing sheet metal