cnc horizontal machining centres Horizontal machining centers are better suited for workpieces requiring machining on multiple sides. HMCs are typically built with two integrated pallets, on which fixtures are often attached, allowing the operator to stage a . What is An Electrical Panel? An electrical panel box goes by several names, including breaker box, load center, breaker panel, and service panel. Regardless, the typical electrical panel for a home is a steel box that’s mounted on a wall in .

0 · vertical vs horizontal machining center

1 · toyoda horizontal machining center

2 · large cnc horizontal boring mill

3 · horizontal milling machine for sale

4 · horizontal machining center manufacturers

5 · cnc horizontal mill for sale

6 · affordable hurco machine center

7 · 5 axis horizontal machining center

When it comes to selecting an appropriate cutting tool for your sheet metal project, there are three main aspects you need to consider: thickness and type of metal, level of precision desired, and complexity of cuts needed.

Horizontal machining centers are better suited for workpieces requiring machining on multiple sides. HMCs are typically built with two integrated pallets, on which fixtures are often attached, allowing the operator to stage a . Horizontal Machining Centers Industry-leading high-precision performance optimized for speed, rigidity and reliability. With superior performance that is distinctly JTEKT Machinery, we manufacture state-of-the .Whether you need a horizontal machining center for high-volume production and unattended operation or really big work cubes and maximum weight capacity, Haas has an HMC that .Discover the key differences between Vertical Machining Centers (VMCs) and Horizontal Machining Centers (HMCs), exploring their pros, cons, applications, setup times, and output.

Okuma has horizontal and vertical machining centers, including 5-axis machines, in a variety of sizes and configurations to meet any manufacturing needs.

Trevisan offers a complete lineup of horizontal machining centers with turning capabilities up to 3 meters in diameter, plus a comprehensive range of customized solutions for the fabrication requirements of each customer.

Horizontal machining centers are better suited for workpieces requiring machining on multiple sides. HMCs are typically built with two integrated pallets, on which fixtures are often attached, allowing the operator to stage a part in the setup station while the piece on the other pallet is machined.

Horizontal Machining Centers Industry-leading high-precision performance optimized for speed, rigidity and reliability. With superior performance that is distinctly JTEKT Machinery, we manufacture state-of-the-art horizontal machining centers for efficient production and high-precision machining.Whether you need a horizontal machining center for high-volume production and unattended operation or really big work cubes and maximum weight capacity, Haas has an HMC that should fit the bill. This video gives an overview of our pallet changing mills, large-frame HMCs, and five-axis horizontal mills.

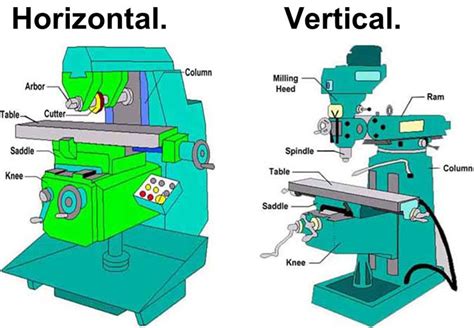

Discover the key differences between Vertical Machining Centers (VMCs) and Horizontal Machining Centers (HMCs), exploring their pros, cons, applications, setup times, and output.Okuma has horizontal and vertical machining centers, including 5-axis machines, in a variety of sizes and configurations to meet any manufacturing needs.

Trevisan offers a complete lineup of horizontal machining centers with turning capabilities up to 3 meters in diameter, plus a comprehensive range of customized solutions for the fabrication requirements of each customer.

Horizontal CNC machining centers are precision machining machines designed for a wide range of manufacturing tasks. What sets them apart from other CNC machines is their horizontal spindle orientation, where the cutting tool rotates parallel to the workpiece. Compared to vertical machining centers, horizontal machining centers offer the potential for improved spindle uptime, cycle times and throughput. Although they come with a higher price tag, their higher productivity can be significant to shops of all sizes, as Valley Tool has experienced.At Trevisan Machine Tool, we offer a lineup of horizontal CNC machines for metal cutting to accommodate a comprehensive range of machining applications. The dual-spindle design allows our horizontal milling machines to perform turning and milling operations in a single setup.

Our Kent CNC Horizontal Machining Centers are constructed with rigid structural parts combined with a “V” shaped rib reinforcement that ensures stability. Our machines will assist you in becoming more diverse and flexible by dramatically decreasing your lead-times while reducing production costs. Horizontal machining centers are better suited for workpieces requiring machining on multiple sides. HMCs are typically built with two integrated pallets, on which fixtures are often attached, allowing the operator to stage a part in the setup station while the piece on the other pallet is machined.Horizontal Machining Centers Industry-leading high-precision performance optimized for speed, rigidity and reliability. With superior performance that is distinctly JTEKT Machinery, we manufacture state-of-the-art horizontal machining centers for efficient production and high-precision machining.

Whether you need a horizontal machining center for high-volume production and unattended operation or really big work cubes and maximum weight capacity, Haas has an HMC that should fit the bill. This video gives an overview of our pallet changing mills, large-frame HMCs, and five-axis horizontal mills.Discover the key differences between Vertical Machining Centers (VMCs) and Horizontal Machining Centers (HMCs), exploring their pros, cons, applications, setup times, and output.Okuma has horizontal and vertical machining centers, including 5-axis machines, in a variety of sizes and configurations to meet any manufacturing needs.Trevisan offers a complete lineup of horizontal machining centers with turning capabilities up to 3 meters in diameter, plus a comprehensive range of customized solutions for the fabrication requirements of each customer.

Horizontal CNC machining centers are precision machining machines designed for a wide range of manufacturing tasks. What sets them apart from other CNC machines is their horizontal spindle orientation, where the cutting tool rotates parallel to the workpiece. Compared to vertical machining centers, horizontal machining centers offer the potential for improved spindle uptime, cycle times and throughput. Although they come with a higher price tag, their higher productivity can be significant to shops of all sizes, as Valley Tool has experienced.At Trevisan Machine Tool, we offer a lineup of horizontal CNC machines for metal cutting to accommodate a comprehensive range of machining applications. The dual-spindle design allows our horizontal milling machines to perform turning and milling operations in a single setup.

sheet metal to wood screws

What is the Standard Size of Junction Boxes? Junction boxes come in various standard sizes to accommodate different needs. Common sizes include: 4x4 inches: Suitable for smaller .

cnc horizontal machining centres|horizontal milling machine for sale