about sheet metal process Sheet metal processing, in essence, is an umbrella term encapsulating a wide array of techniques employed to manipulate and transform flat sheets of various metals into specific shapes and forms. Why Sheet Metal Processing is . This Yu-Gi-Oh! Metal Raiders booster box is the perfect addition to any collector's stash. With 216 cards made of high-quality card stock, this box is sure to contain a variety of unique cards to add to your collection.

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal working process pdf

4 · sheet metal process pdf

5 · sheet metal process in manufacturing

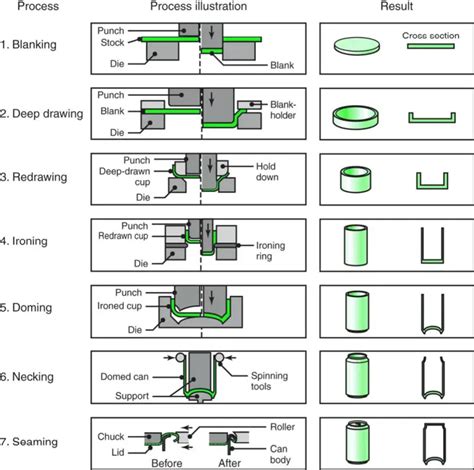

6 · sheet metal operations with diagrams

7 · sheet metal fabrication pdf

The best part, imho: New Old Stock Cusheen vinyl countertops to match up with the Youngstown Steel Kitchen cabinet bases. There are a lot of steel kitchen cabinets around (of course, not NOS), and there are a lot of GE ranges around (ditto) .

various sheet metal processes

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal . Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly .The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In .

Sheet metal processing, in essence, is an umbrella term encapsulating a wide array of techniques employed to manipulate and transform flat sheets of various metals into specific shapes and forms. Why Sheet Metal Processing is .

types of sheet metal process

types of sheet metal fabrication

Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes. Sheet metal forming, encompassing techniques such as bending, stretching, and deep drawing, plays a pivotal role in creating lightweight yet durable components essential for modern engineering applications. In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components.

What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms.

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In this article, we’ll explore the nine vital steps in sheet metal fabrication, providing valuable insights for businesses and industry professionals.Sheet metal processing, in essence, is an umbrella term encapsulating a wide array of techniques employed to manipulate and transform flat sheets of various metals into specific shapes and forms. Why Sheet Metal Processing is Important?

Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes. Sheet metal forming, encompassing techniques such as bending, stretching, and deep drawing, plays a pivotal role in creating lightweight yet durable components essential for modern engineering applications.

onyx solar junction box

In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more.

Imagine turning a flat sheet of metal into a complex, three-dimensional part with precision and efficiency. The art and science of sheet metal fabrication involve a series of meticulous processes, from designing and cutting to bending and welding. Sheet metal forming is an essential process used in industries such as automobile construction and manufacturing. It involves shaping flat sheets of metal into three-dimensional objects. This guide explores the beginning to end application process and covers forming techniques, equipment, challenges, and materials involved. In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms.

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In this article, we’ll explore the nine vital steps in sheet metal fabrication, providing valuable insights for businesses and industry professionals.

Sheet metal processing, in essence, is an umbrella term encapsulating a wide array of techniques employed to manipulate and transform flat sheets of various metals into specific shapes and forms. Why Sheet Metal Processing is Important?Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes. Sheet metal forming, encompassing techniques such as bending, stretching, and deep drawing, plays a pivotal role in creating lightweight yet durable components essential for modern engineering applications.

In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more.

Imagine turning a flat sheet of metal into a complex, three-dimensional part with precision and efficiency. The art and science of sheet metal fabrication involve a series of meticulous processes, from designing and cutting to bending and welding.

sheet metal working process pdf

Evolution of the famous Cardboard Box throughout the Metal Gear Series. Timeline: 00:00 - Metal Gear (1987) 00:36 - Metal Gear 2: Solid Snake (1990) 02:20 - Metal Gear Solid (1998) 06:58 - Metal Gear Solid 2: Sons of Liberty (2001) 13:27 - Metal Gear Solid 3: Snake Eater (2004) 18:04 - Metal Gear Solid: Portable Ops (2006) 19:07 - Metal Gear .

about sheet metal process|sheet metal process in manufacturing