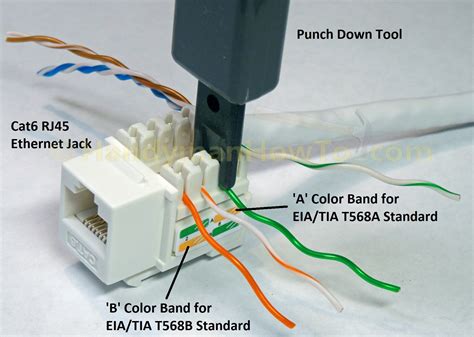

electrical work box management punchdown Ethernet punch down is a process used in networking to terminate and connect Ethernet cables to a patch panel or wall jack. It involves punching down the individual wires from the Ethernet cable into the corresponding slots on the punch down block. This helps create a secure and reliable connection for network devices. Find the special pin included with your device in the box. It should be a small metal rod that’s oval in shape.

0 · punch down wiring diagram

1 · punch down wire repair

2 · punch down tools for cable

3 · punch down tools

4 · punch down ethernet panels

5 · punch down circuit diagram

6 · how do punch down tools work

7 · 110 punch down wiring

What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms.

It works by inserting the wire for corrosion-resistant termination and then trims off excess wire, which ensures fast and precise connections with less effort. This article focuses . FS provides a comprehensive range of Ethernet patch panels, including punch down, coupler, and blank keystone panels, catering to diverse networking needs. Punch down patch panels offer reliable termination points for network . A must-have item in cable installations and for stepping up cabling work efficiency. In this post, we will define what punch down tools are, how they work, and how to use them effectively. Punch Down Tools Explained. Punch down tools allow for quick and effective cross-connection of wires.

enameled metal bread box

It works by inserting the wire for corrosion-resistant termination and then trims off excess wire, which ensures fast and precise connections with less effort. This article focuses on ethernet punch down tool types, and explains how to use a punch down tool.Ethernet punch down is a process used in networking to terminate and connect Ethernet cables to a patch panel or wall jack. It involves punching down the individual wires from the Ethernet cable into the corresponding slots on the punch down block. This helps create a secure and reliable connection for network devices.

Like a feed-through patch panel, a monolithic patch panel has permanently-installed RJ45 output ports. These ports are connected to the solid copper infrastructure cable using punch-down 110 IDC terminals.Klein Tools multi-bit punchdown screwdriver / nut driver gives you the convenience of manually punching down wall jacks and patch panels. With its machined tool steel for greaterIn this video, you’ll learn about cable management techniques, patch panels, and punch-down block options.

The punch-down process involves placing the Ethernet cable's individual wires into their designated slots and using the punch-down tool to push the wires into place. The tool trims any excess wire and ensures a secure and reliable .ShowMeCables offers a wide variety of punchdown tools. Use simple tools for small projects or powerful impact punchdowns for large-scale installations. With same-day shipping options, our punchdown tools are ready to ship today.

Its design prevents plugs from slipping out of your hand or off the work surface prior to termination. It terminates and cuts excess wire for all eight wires in one squeeze reducing installation time. This palm puck punch down tool is compatible with CAT3/5E/6 keystone jacks. Complete the Network! FS provides a comprehensive range of Ethernet patch panels, including punch down, coupler, and blank keystone panels, catering to diverse networking needs. Punch down patch panels offer reliable termination points for network . A must-have item in cable installations and for stepping up cabling work efficiency. In this post, we will define what punch down tools are, how they work, and how to use them effectively. Punch Down Tools Explained. Punch down tools allow for quick and effective cross-connection of wires. It works by inserting the wire for corrosion-resistant termination and then trims off excess wire, which ensures fast and precise connections with less effort. This article focuses on ethernet punch down tool types, and explains how to use a punch down tool.

Ethernet punch down is a process used in networking to terminate and connect Ethernet cables to a patch panel or wall jack. It involves punching down the individual wires from the Ethernet cable into the corresponding slots on the punch down block. This helps create a secure and reliable connection for network devices.Like a feed-through patch panel, a monolithic patch panel has permanently-installed RJ45 output ports. These ports are connected to the solid copper infrastructure cable using punch-down 110 IDC terminals.

Klein Tools multi-bit punchdown screwdriver / nut driver gives you the convenience of manually punching down wall jacks and patch panels. With its machined tool steel for greater

In this video, you’ll learn about cable management techniques, patch panels, and punch-down block options. The punch-down process involves placing the Ethernet cable's individual wires into their designated slots and using the punch-down tool to push the wires into place. The tool trims any excess wire and ensures a secure and reliable .ShowMeCables offers a wide variety of punchdown tools. Use simple tools for small projects or powerful impact punchdowns for large-scale installations. With same-day shipping options, our punchdown tools are ready to ship today.

punch down wiring diagram

The process involves the sheet metal being placed over a die, then pressed with a punch into an open cavity, causing the material to undergo plastic deformation. The process allows for precisely made complex shapes and designs with deeper features.

electrical work box management punchdown|punch down wire repair