sheet metal seal corner without welding Need to stick some metal to metal but don’t have access to a welder? You’re not necessarily out of options. Welding is usually the best way to go, but there might be a few alternatives that could work good enough for you. eMachineShop offers cost-effective milling service whether you need a single part, batch of prototypes, or full production order. 50+ Materials. FREE Shipping in the USA. 100% Quality Guaranteed. CNC milling has a number of advantages over other manufacturing processes. Milling machines can operate at high speeds, producing parts quickly.

0 · Using Captive Nuts to Join Sheet Metal Parts Without

1 · The Easiest Way to Join Metal Without Welding

2 · Making a corner in sheetmetal for a dust tight box

3 · How to Fill Holes in Metal without Welding (Quick

4 · How to Design Bend Reliefs & Corner Reliefs for Sheet Metal Parts

5 · How to Bond Metal to Metal without Welding (Quick

6 · How to Bond Metal Without Welding – Make It From

7 · How To Bond Metal To Metal Without Welding

8 · Bond Two Pieces of Metal Without Welding: 10 Easy Ways

9 · 5 Methods to Effectevly Join Metals Without a Welder

Precision CNC machined automotive and motorcycle parts. Custom auto parts prototype and motorcycle parts production. Parts in excellent dimensional accuracy, quality, and on-time delivery

One place we have trouble with is getting the corners to seal up without resorting to welding. Something we've seen uses a feature like this: The small web of material formed .

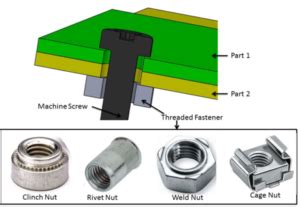

In this blog post, we’ll explore the concept of captive nuts—a simple yet effective solution for creating sturdy assemblies without welding. We’ll cover what captive nuts are, how to use them effectively, the importance of . Maybe you don’t have a welder, or the job requires a solution that allows for easy disassembly later. In this video, we’re diving into a method that’s both simple and effective: Captive Nuts. Once you’re through with cutting and fitting the metal sheet into size, use a file or emery cloth to round the patch’s corners. It stops any sharp nooks from becoming catching areas for ice or snow.

Need to stick some metal to metal but don’t have access to a welder? You’re not necessarily out of options. Welding is usually the best way to go, but there might be a few alternatives that could work good enough for you.

There are numerous methods for joining metals without welding. Read down below to find out how to join two pieces of metal without welding. Some of these alternatives to welding methods require heat while some don’t require heat at . Ways To Bond Metal To Metal Without Welding. Learning how to combine metals without welding is not difficult. For joining metals, there are a metal of non-welding methods. Some require heat, but at lower temperatures, . Here are the main steps for bonding metal pieces using the brazing method: Make sure of a good fit: the connection between the two base metals should be clear to allow for effective capillary action. Clean metals: clean .

Proper panel forming is paramount. Cutting and prepping the joint but only after knowing where to locate it, you see a dolly needs to be able to be placed there. Then there's the welding process - itself lots of practice required. If this was your first ever sheet metal butt weld I'd try more practice first. In addition, they require a large amount of weld metal. Types of Corner Joint. There are many different types of corner joints that can be used when joining two pieces of wood together. The most common type of joints .

Choose from our selection of sheet metal corners, including multipurpose aluminum, stainless steel, and more. . Shield corners on walls and other surfaces from impact. . through equally spaced holes to build and adjust guards, tables, and racks. 13 products. Fastening and Joining. Weld Nuts. Weld to metal surfaces to add permanent threads .

1. Brazing: The Most Relevant Alternative to Welding. Compared with soldering, fastening, and other options for joining metal, welding and brazing are more effective when the joints are expected to be permanent and strong. Both methods are commercially viable, but they work differently. I try very hard NOT to try any corner welds on material less than 2-3 mm thick without a lap joint or a tab folded at the corner. 0.9 mm to 0.9 mm at a "free folded corner with no backing metal is very tricky to avoid burn-through and re-re-re-rework. Fold the corners up so there is a backing piece behind the two plates.You can make watertight trays from flat sheet metal without soldering or riviting. Take a sheet of metal whose. length is the length of the finished tray plus two time the height of the sides; width is the width of the finished tray plus two time the height of the sides. Fold the sheet so it ends up looking like this: Table of Contents. 1 Spot Weld vs. Seam Weld; 2 7 Things to Know About Spot Welding ; 3 Sheet Metal Part Design for Manufacturing Tip. 3.1 CORNERS AND WELDING; 4 Spot Welding FAQ. 4.0.1 What is the difference between spot welding and seam welding, and when should I choose one over the other?; 4.0.2 What is plug welding, and when should I .

sheet metal enclosure fabrication,forming sheet metal corners without welding*****Whats.

Using Captive Nuts to Join Sheet Metal Parts Without

2 Approved Sheet Metal’s Proven Approach to Corner Construction; 3 Sheet Metal Part Design for Manufacturing Tip. 3.1 CORNERS AND WELDING; 4 Metal Fabrication Corner Construction FAQ. 4.0.1 Why is proper corner construction crucial in sheet metal fabrications? 4.0.2 How does Approved Sheet Metal ensure high-quality corners in every fabrication?

See how and when specifically to design bend reliefs and corner reliefs in sheet metal parts to open up geometry options & tighter tolerances. Materials; Services; Guidelines; FAQ; Blog; . For example a corner between two bends that you want to seal up after bending. An obround relief can minimize the gap and make welding or seam sealing . Ways To Bond Metal To Metal Without Welding. Learning how to combine metals without welding is not difficult. For joining metals, there are a metal of non-welding methods. Some require heat, but at lower temperatures, while others rely on diverse adhesive methods. Let’s look at how to join two metal parts together without requiring welding.Read down below to find out how to join two pieces of metal without welding. Some of these alternatives to welding methods require heat while some don’t require heat at all. 1. GLUE. Contents. 1. . However, for sheet metal, you can easily buy some small rivets as well as rivet pliers from Amazon. I have done quite a lot of riveting in my .

You can not create sturdy structures without producing top-notch seal welds. If you are completely new to welding, then maybe you do not have an idea of what is a seal weld. The main objective of seal weld is to get resilience against the outflows as they stop the fluids, either liquids or gases, from getting into the cavity.

folding is a process that should be taken slow, hopefully I've provided sufficient photos to walk you through it. start close to a corner and fold towards you if using a vise. help the crease fold outward with a screwdriver and pliers. when you move to the next side stay close to your best looking corner and pinch the corner crease while . Welding in patch panels with a flux-core welder without a gas envelope is an exercise in burn-through and swearing—so glue it was. And maybe the epoxy would result in a more rustproof seam. . I then used the . In this blog post, we’ll discuss three ways to fix broken metal without welding. Keep reading for more information! 10 ways to fix broken metal without welding. 1. Use a strong adhesive. There are many strong adhesives .Why welding is a popular method of joining metal to metal. We should start by clarifying that you can also weld plastics, but this article is focused on welding metal to metal. There are several different types of welding. The three most .

1.These left and right trunk floor extensions (part No. 840-2570-L, 840-2570-R, 9.99 each) from Auto Metal Direct will replace the rotted-out sections on our E-Body project. With adhesive you need two 100% cleaned metal sides to apply the adhesive too, clamp or mechanical connection, screws or rivets. So, if your lapping your corners, new corner overlapping body by a few inches , adhesive will work fine. . How to fill holes in sheet metal without welding.This video is an update to an older video of mine on how to solder holes. Here I show in more detail how you.

Contents. 1 Understanding The Importance Of Proper Hole Filling. 1.1 Common Issues Caused By Unfilled Holes:; 1.2 The Benefits Of Filling Holes In Metal:; 2 Necessary Tools And Materials. 2.1 Essential Tools For Hole Filling:; 2.2 Selecting The Right Materials:; 3 Preparing The Surface. 3.1 Cleaning The Metal Surface; 3.2 Removing Rust And Debris; 4 . Chapter #6 – Sheet Metal Seams. Seams run longitudinal along the length of the duct run, while joints run transverse (across). Seams run parallel to the air flow, while joints are perpendicular to the air flow. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together. weld within a part (or sheet metal part). As previously stated: - open a new/empty weldment.iam file - place your sheet metal file - place the welds required to close your corners - save the weldment.iam - make a drawing of the weldment showing the beads with callouts - create any flat pattern drawings from the original sheet metal file-- Gary .That paint isn't going to stop that rust for more than about 5 minutes or so. The correct way to fix this is to cut out all the rust and weld in new metal. If that method isn't possible, you could back it with some galvanized sheet metal and use bondoglas or fiberglass cloth to do a cosmetic repair, but it won't last.

Another joint type in sheet metal work is the flush corner joint. A flush corner joint is only used on lighter sheet metal (12 gauge or lower). The reason for this is because getting good penetration is challenging and it cannot handle significant loads. . The difficulty in welding sheet metal is that you need to get good penetration to make .One option would be instead of having the break be equal on the corner have your long edges go flush with the o.s. of the part. This would make it so when you look at the part from the top view instead of seeing 90 degrees in the corner that needs weld it would be flush.If the metal is seated properly it should work. I have a few plans for model steam engines and many of their seals like for the safety release valve are metal on metal. Some of the construction notes besides being specifically machines are to tap .

The Easiest Way to Join Metal Without Welding

eMachineShop manufactures low-cost prototype and production runs of custom parts. Get a fast quote or design and order your parts with our free CAD software. We offer CNC Milling and Turning, Sheet Metal Fabrication, Injection Molding, and dozens of materials.

sheet metal seal corner without welding|How to Bond Metal to Metal without Welding (Quick