drawings for metal fabrication 2D drawings serve as the bedrock for manufacturing industries, acting as the blueprint for every process, including sheet metal fabrication. These technical drawings encapsulate the design intent, detailing every aspect, from . The Wolverine® Insulated Lunch Box is a durable companion for fresh food and beverages. Made of high-density canvas with a durable water-repellent (DWR) coating, it repels both dirt and water. The large insulated compartment holds .

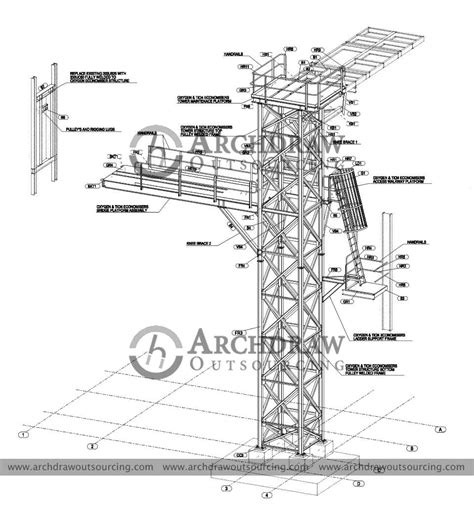

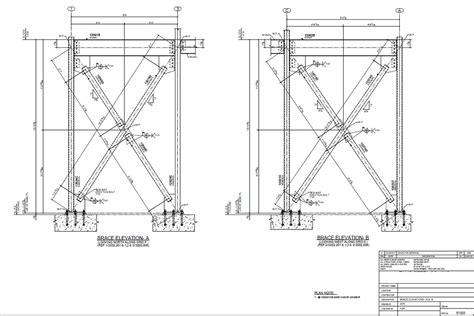

0 · structure fabrication drawing

1 · structural steel shop drawings

2 · structural steel fabrication drawings

3 · structural steel detail drawings

4 · structural shop drawings

5 · sheet metal design drawings

6 · metal fabrication drawing symbols

7 · how to read fabrication drawings

The best wood laser engravers blend your artistic endeavors with powerful design software while saving you time, money, and costly errors. Based on extensive hands-on testing, here’s our top recommendations for wood laser cutting:

5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. Follow these best practices next time you create a sheet metal fabrication drawing to help your shop turn the project around quickly: 1. . This article will provide a series of key sheet metal design and fabrication guidelines to help engineers and designers understand how to maximize the use of the characteristics of metal sheets, ensuring the feasibility . 2D drawings serve as the bedrock for manufacturing industries, acting as the blueprint for every process, including sheet metal fabrication. These technical drawings encapsulate the design intent, detailing every aspect, from .Interpreting metal fab drawings is a course that introduces the principles of interpretation and application of industrial fabrication drawings. Basic principles and techniques of metal fabrication are introduced by planning and .

Unlock the secrets to precise fabrication with our expert guide on detailing sheet metal shop drawings. Enhance accuracy and efficiency in your projects. Read more!In this section we will be considering four foundational DFM considerations in order to create great sheet metal drawings. Sheet metal parts require a sequence of manufacturing processes to transition from raw stock material to finished part.

Our design guide to properly drafting sheet metal drawings and specifications for your supplier to get more accurate quotes and faster design for manufacturing (DFM) feedback. Fabrication drawings play a crucial role in the manufacturing and construction industries, providing detailed visual representations of the components and structures that must be fabricated. These drawings guide .

structure fabrication drawing

In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency. 5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. Follow these best practices next time you create a sheet metal fabrication drawing to help your shop turn the project around quickly: 1. List part numbers, not just the part name. Part names are great, but it’s helpful to provide part numbers, too. This article will provide a series of key sheet metal design and fabrication guidelines to help engineers and designers understand how to maximize the use of the characteristics of metal sheets, ensuring the feasibility of .

Fabrication shop drawings are detailed drawings in the steel industry that a fabricator, manufacturer, or contractor makes. These drawings represent fabrication standards, elevations, and sections with welding data and dimensions.

2D drawings serve as the bedrock for manufacturing industries, acting as the blueprint for every process, including sheet metal fabrication. These technical drawings encapsulate the design intent, detailing every aspect, from dimensions and tolerances to material specifications and finish requirements.Interpreting metal fab drawings is a course that introduces the principles of interpretation and application of industrial fabrication drawings. Basic principles and techniques of metal fabrication are introduced by planning and construction of fixtures used in fabrication from drawings. Unlock the secrets to precise fabrication with our expert guide on detailing sheet metal shop drawings. Enhance accuracy and efficiency in your projects. Read more!In this section we will be considering four foundational DFM considerations in order to create great sheet metal drawings. Sheet metal parts require a sequence of manufacturing processes to transition from raw stock material to finished part.

Our design guide to properly drafting sheet metal drawings and specifications for your supplier to get more accurate quotes and faster design for manufacturing (DFM) feedback. Fabrication drawings play a crucial role in the manufacturing and construction industries, providing detailed visual representations of the components and structures that must be fabricated. These drawings guide fabricators, welders, and technicians, ensuring accurate and precise fabrication processes with every functional information documented.In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency.

5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. Follow these best practices next time you create a sheet metal fabrication drawing to help your shop turn the project around quickly: 1. List part numbers, not just the part name. Part names are great, but it’s helpful to provide part numbers, too. This article will provide a series of key sheet metal design and fabrication guidelines to help engineers and designers understand how to maximize the use of the characteristics of metal sheets, ensuring the feasibility of . Fabrication shop drawings are detailed drawings in the steel industry that a fabricator, manufacturer, or contractor makes. These drawings represent fabrication standards, elevations, and sections with welding data and dimensions.

2D drawings serve as the bedrock for manufacturing industries, acting as the blueprint for every process, including sheet metal fabrication. These technical drawings encapsulate the design intent, detailing every aspect, from dimensions and tolerances to material specifications and finish requirements.

Interpreting metal fab drawings is a course that introduces the principles of interpretation and application of industrial fabrication drawings. Basic principles and techniques of metal fabrication are introduced by planning and construction of fixtures used in fabrication from drawings.

Unlock the secrets to precise fabrication with our expert guide on detailing sheet metal shop drawings. Enhance accuracy and efficiency in your projects. Read more!In this section we will be considering four foundational DFM considerations in order to create great sheet metal drawings. Sheet metal parts require a sequence of manufacturing processes to transition from raw stock material to finished part. Our design guide to properly drafting sheet metal drawings and specifications for your supplier to get more accurate quotes and faster design for manufacturing (DFM) feedback.

Fabrication drawings play a crucial role in the manufacturing and construction industries, providing detailed visual representations of the components and structures that must be fabricated. These drawings guide fabricators, welders, and technicians, ensuring accurate and precise fabrication processes with every functional information documented.

structural steel shop drawings

automotive sheet metal welder

structural steel fabrication drawings

Wonder Woman fabric empowering You Got this saying for women and girls. Great fabric for quilting, crafts or home decor items, pillow covers and bed skirts.

drawings for metal fabrication|structural steel shop drawings