drawing sheet metal process Drawing is a manufacturing process that uses tensile forces to elongate metal, glass, or plastic. As the material is drawn (pulled), it stretches and becomes thinner, achieving a desired shape and thickness. Drawing is classified into two types: sheet metal drawing and wire, bar, and tube drawing. Sheet metal drawing is defined as a plastic deformation over a curved axis. For wire, bar, and tube dra. Modern WorkPro 42" 5-drawer steel lateral file cabinet in black. GREENGUARD Gold certified — certified for low chemical emissions: UL.COM/GG - UL 2818. Ranked in two tiers: Certified and Gold.

0 · simple sheet metal drawings

1 · sheet metal forming drawing

2 · sheet metal diagram fabrication

3 · sheet metal deep drawing calculations

4 · sheet metal basic drawing

5 · metal spinning vs deep drawing

6 · metal sheet mechanical drawings

7 · deep drawing in sheet metal

$149.99

A complete guide to the world of sheet metal drawing, its processes, applications, benefits, and Prolean’s Sheet Metal Drawing Services.Drawing is a manufacturing process that uses tensile forces to elongate metal, glass, or plastic. As the material is drawn (pulled), it stretches and becomes thinner, achieving a desired shape and thickness. Drawing is classified into two types: sheet metal drawing and wire, bar, and tube drawing. Sheet metal drawing is defined as a plastic deformation over a curved axis. For wire, bar, and tube dra. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels .

Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking.

Sheet metal drawing is a manufacturing process used to form flat sheet metal into a desired shape using a die and a press. Used to create complex shapes and structures from flat metal sheets. Sheet metal drawings, on the . Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to .

The metal drawing process is a fundamental manufacturing technique that transforms metal materials into desired shapes and structures through the application of force. Widely used in various industries, such as .

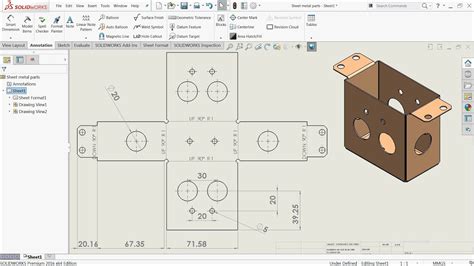

Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various .In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency. A complete guide to the world of sheet metal drawing, its processes, applications, benefits, and Prolean’s Sheet Metal Drawing Services.

Drawing is a manufacturing process that uses tensile forces to elongate metal, glass, or plastic. As the material is drawn (pulled), it stretches and becomes thinner, achieving a desired shape and thickness. Drawing is classified into two types: sheet metal drawing and . What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.

Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking. Sheet metal drawing is a manufacturing process used to form flat sheet metal into a desired shape using a die and a press. Used to create complex shapes and structures from flat metal sheets. Sheet metal drawings, on the other hand, detail the parts according to the characteristics and requirements of this processing technique. Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.

The metal drawing process is a fundamental manufacturing technique that transforms metal materials into desired shapes and structures through the application of force. Widely used in various industries, such as automotive, aerospace, and construction, metal forming encompasses a diverse range of methods, including bending, stamping, rolling . Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products.

In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency. A complete guide to the world of sheet metal drawing, its processes, applications, benefits, and Prolean’s Sheet Metal Drawing Services.Drawing is a manufacturing process that uses tensile forces to elongate metal, glass, or plastic. As the material is drawn (pulled), it stretches and becomes thinner, achieving a desired shape and thickness. Drawing is classified into two types: sheet metal drawing and . What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms.

These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking. Sheet metal drawing is a manufacturing process used to form flat sheet metal into a desired shape using a die and a press. Used to create complex shapes and structures from flat metal sheets. Sheet metal drawings, on the other hand, detail the parts according to the characteristics and requirements of this processing technique.

Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few. The metal drawing process is a fundamental manufacturing technique that transforms metal materials into desired shapes and structures through the application of force. Widely used in various industries, such as automotive, aerospace, and construction, metal forming encompasses a diverse range of methods, including bending, stamping, rolling . Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products.

simple sheet metal drawings

sheet metal forming drawing

sheet metal diagram fabrication

In this article, we'll go over the basics of how to work with sheet metal, from cutting and bending to welding and finishing. You can produce quality fabricated parts from your shop by understanding the basics.

drawing sheet metal process|deep drawing in sheet metal