3 axis cnc milling machine factory Bridgeport has various product offerings of 3 Axis capable CNC mills that can fit a variety of manufacturing requirements. Old work electrical boxes are used when you need to add an electrical box to walls that are closed in or covered with drywall. These boxes are designed to clamp into the drywall and don't.

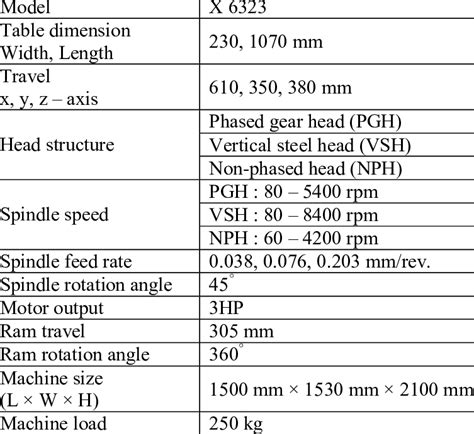

0 · specifications of cnc milling machine

1 · small 3 axis cnc mill

2 · datron cnc price list

3 · axis identification in cnc machine

4 · 3 axis vertical milling machine

5 · 3 axis manual milling machine

6 · 3 axis cnc table

7 · 3 axis cnc machine price

Feed rate defines the speed at which a cutting tool moves through a workpiece during machining. Optimal feed rates are crucial for achieving high precision, efficiency, and surface finish .

Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table .Bridgeport has various product offerings of 3 Axis capable CNC mills that can fit a variety of manufacturing requirements.In their simplest design, milling machines are set up for 3-axis machining: the tool moves over the workpiece in the X, Y and Z direction. A rotary axis, in the headstock or the table for example, extends the range of machining because .The industry’s leading series of high-speed milling solutions, the Mikron HSM 500 3-axis vertical CNC milling machines let any manufacturer meet the challenge of delivering speed and quality at the highest level.

specifications of cnc milling machine

small 3 axis cnc mill

Find your 3-axis cnc milling machine easily amongst the 553 products from the leading brands (MECANUMERIC, Knuth Machine Tools, ROLAND, .) on DirectIndustry, the industry specialist for your professional purchases.We have added two new models in the most sought after table sizes: 9" x 49" and 19" x 54" hardened and ground bedways. They are made under the strictest quality control in Taiwan and are tested by three sets of engineers - Factory's, .

As a dependable milling option for many components, 3-axis milling is well-suited for milling simple, large, or high-volume parts. Designed for automatic operation, Miller CNC can build fixtures that hold multiple parts to cut, all in one setup.

Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle.

Bridgeport has various product offerings of 3 Axis capable CNC mills that can fit a variety of manufacturing requirements.In their simplest design, milling machines are set up for 3-axis machining: the tool moves over the workpiece in the X, Y and Z direction. A rotary axis, in the headstock or the table for example, extends the range of machining because components can also be positioned at an angle.The industry’s leading series of high-speed milling solutions, the Mikron HSM 500 3-axis vertical CNC milling machines let any manufacturer meet the challenge of delivering speed and quality at the highest level.

Find your 3-axis cnc milling machine easily amongst the 553 products from the leading brands (MECANUMERIC, Knuth Machine Tools, ROLAND, .) on DirectIndustry, the industry specialist for your professional purchases.

We have added two new models in the most sought after table sizes: 9" x 49" and 19" x 54" hardened and ground bedways. They are made under the strictest quality control in Taiwan and are tested by three sets of engineers - Factory's, Centroid™'s and Grizzly's - all together!Milling Head with Tilting Mechanism. 1″ Diameter Ball Screws with Cast Mounting Brackets. Dual Knee, Table and Saddle Locks. Precision 3 3/8″ Diameter Hard Chromed Quill @ HRC 62. Auto Lubrication System. Mechanical Specifications: Dimensions: 96″ x 62″ x 89″ H. Weight: approx. 3,050 lbs. Contact us for special pricing and .Process stability and long-term accuracy - Whether you’re in parts production or a mold and die maker, GF Machining Solutions' vertical 3-axis CNC milling machines range offers you a state-of-the-art design and stiff machine base with high-tech key components.Looking for a 3-axis CNC aluminum machine to cut precise aluminum parts? We’ve got you covered! Shapeoko HDM: High power, great for heavy-duty tasks. PrintNC: Custom build, known for its rigidity. Nomad 3: Ideal for hobbyists and light aluminum cutting. G0704: Vertical mill perfect for conversions.

As a dependable milling option for many components, 3-axis milling is well-suited for milling simple, large, or high-volume parts. Designed for automatic operation, Miller CNC can build fixtures that hold multiple parts to cut, all in one setup.Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle.Bridgeport has various product offerings of 3 Axis capable CNC mills that can fit a variety of manufacturing requirements.

datron cnc price list

In their simplest design, milling machines are set up for 3-axis machining: the tool moves over the workpiece in the X, Y and Z direction. A rotary axis, in the headstock or the table for example, extends the range of machining because components can also be positioned at an angle.

The industry’s leading series of high-speed milling solutions, the Mikron HSM 500 3-axis vertical CNC milling machines let any manufacturer meet the challenge of delivering speed and quality at the highest level.Find your 3-axis cnc milling machine easily amongst the 553 products from the leading brands (MECANUMERIC, Knuth Machine Tools, ROLAND, .) on DirectIndustry, the industry specialist for your professional purchases.

We have added two new models in the most sought after table sizes: 9" x 49" and 19" x 54" hardened and ground bedways. They are made under the strictest quality control in Taiwan and are tested by three sets of engineers - Factory's, Centroid™'s and Grizzly's - all together!

Milling Head with Tilting Mechanism. 1″ Diameter Ball Screws with Cast Mounting Brackets. Dual Knee, Table and Saddle Locks. Precision 3 3/8″ Diameter Hard Chromed Quill @ HRC 62. Auto Lubrication System. Mechanical Specifications: Dimensions: 96″ x 62″ x 89″ H. Weight: approx. 3,050 lbs. Contact us for special pricing and .Process stability and long-term accuracy - Whether you’re in parts production or a mold and die maker, GF Machining Solutions' vertical 3-axis CNC milling machines range offers you a state-of-the-art design and stiff machine base with high-tech key components.

If the box was installed recently in accordance with National Electrical Code (NEC), the box should be labeled if it's rated to support a ceiling fan. NEC 2008 314.27 Outlet Boxes. (D) Boxes at Ceiling-Suspended (Paddle) Fan Outlets.

3 axis cnc milling machine factory|datron cnc price list