240 to junction box For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), then stick a 2-gang "mud ring" . Plastic, commonly injection molded, can also be thermoformed, extruded and machined. Metals, commonly machined, can be die-cast, stamped and extruded. Large-volume production of metal parts is typically done using casting or forging. Nearly every industry uses metal and plastic.

0 · electrical box for 240v range

1 · clipsal junction box

2 · b&q electrical junction box

3 · 240v junction box wiring

4 · 240 volt junction box

5 · 240 volt electrical junction box

6 · 240 volt breaker box

7 · 240 amp breaker box

In essence, it’s nothing more than the ratio of the sheet metal thickness to the neutral axis, i.e. between t (distance between the inside of the bend and the neutral plane) and T (the workpiece thickness).Nesting is an important aspect of production, ensuring work is completed efficiently in terms of time and material. Read all about it.

For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), then stick a 2-gang "mud ring" .Can I run the new line by attaching to the old one using the junction box. They just .As long as the existing dryer connection is 4-wire, or is 3-wire with insulated neutral .

Can I run the new line by attaching to the old one using the junction box. They just disconnected it and turned off the breaker. I would like to reuse the line for another item .

For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), then stick a 2-gang "mud ring" on it, then stick plain 120V receptacles or switches there, fed by totally separate 120V / #12 wires. Can I run the new line by attaching to the old one using the junction box. They just disconnected it and turned off the breaker. I would like to reuse the line for another item requiring 240 power in my garage. Can this be done and still follow code? Key questions: What size wire from breaker to junction box? How many wires?

As long as the existing dryer connection is 4-wire, or is 3-wire with insulated neutral and solid metal conduit back to the panel, then it may be extended. Use a junction box extension, or a surface conduit system like Legrand Wiremold.

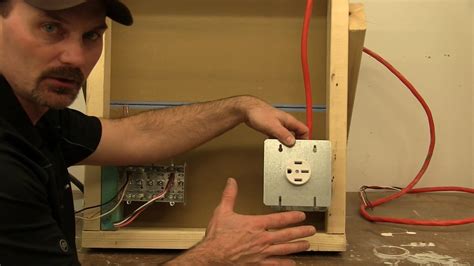

Here I'll show you how to wire a 120/240V, 30-amp dryer outlet that accepts a four-prong grounded plug. The National Electric Code (NEC) requires this configuration for new construction. If your home was built before 1996, you may have a three-prong dryer plug and a circuit without an equipment ground. The only way to extend the circuit is to retrofit ground to the original location, see NEC 250.130(C). This is a 10 AWG wire to any junction box containing a #10 or larger wire which is going back to the same panel. It can also go to the bare wire from the panel to your ground rods. Never cut that wire, use a split-bolt to attach to it. Electrical - AC & DC - 240 volt junction box - I'm remodeling my kitchen, and moving my wall oven to another wall in the kitchen. Is it an acceptable practice to simply cut and abandon the wire in its current location and wire nut a new wire to go to the new spot?

I'm thinking that I need to run a brand new 240 line from the panel to where it's going to go - not a tough job. But I was thinking, is there a way to splice something together to get that extra 5 ft? It's fine. Just make sure the junction box remains accessible and the wire is protected from damage. Is it okay to junction it into a near by 120v plug. Splice it in the microwave outlet box. The microwave needs 240 anyways to cook your hotdogs fast. Depends on box fill. Call an electrician. didn't they both come from the same panel? Box fill is the code-issue here.

I was talking to a friend, and he said you can run a 240 and 120 to a 4in handi box using 12/3 wire. Basically, one receptacle would be 240 volts and one would be 120v (both are 20 amps). I understand how he could wire it this way, but I don't think it would be code. For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), then stick a 2-gang "mud ring" on it, then stick plain 120V receptacles or switches there, fed by totally separate 120V / #12 wires. Can I run the new line by attaching to the old one using the junction box. They just disconnected it and turned off the breaker. I would like to reuse the line for another item requiring 240 power in my garage. Can this be done and still follow code? Key questions: What size wire from breaker to junction box? How many wires?

As long as the existing dryer connection is 4-wire, or is 3-wire with insulated neutral and solid metal conduit back to the panel, then it may be extended. Use a junction box extension, or a surface conduit system like Legrand Wiremold. Here I'll show you how to wire a 120/240V, 30-amp dryer outlet that accepts a four-prong grounded plug. The National Electric Code (NEC) requires this configuration for new construction. If your home was built before 1996, you may have a three-prong dryer plug and a circuit without an equipment ground.

The only way to extend the circuit is to retrofit ground to the original location, see NEC 250.130(C). This is a 10 AWG wire to any junction box containing a #10 or larger wire which is going back to the same panel. It can also go to the bare wire from the panel to your ground rods. Never cut that wire, use a split-bolt to attach to it. Electrical - AC & DC - 240 volt junction box - I'm remodeling my kitchen, and moving my wall oven to another wall in the kitchen. Is it an acceptable practice to simply cut and abandon the wire in its current location and wire nut a new wire to go to the new spot?I'm thinking that I need to run a brand new 240 line from the panel to where it's going to go - not a tough job. But I was thinking, is there a way to splice something together to get that extra 5 ft? It's fine. Just make sure the junction box remains accessible and the wire is protected from damage.

Is it okay to junction it into a near by 120v plug. Splice it in the microwave outlet box. The microwave needs 240 anyways to cook your hotdogs fast. Depends on box fill. Call an electrician. didn't they both come from the same panel? Box fill is the code-issue here.

electrical box for 240v range

clipsal junction box

b&q electrical junction box

Sheet metal can be made of a variety of materials, including copper, aluminum, steel and titanium. There are four basic stages in the process of making sheet metal: melting, .

240 to junction box|electrical box for 240v range