cnc cutter grinding machines News - The World's Most Flexible Tool Grinder - ANCA - CNC Machines

In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, and share tips to help you design the ideal custom brackets for your applications.

0 · walter tool and cutter grinder

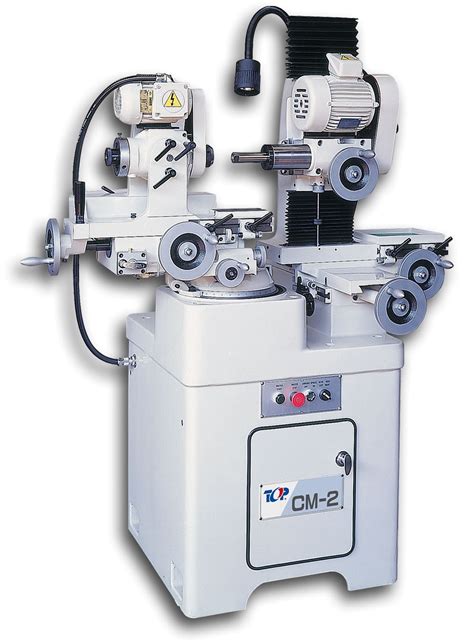

1 · universal tool cutter grinder machine

2 · universal tool and cutter grinders

3 · tool and cutter grinder diagram

4 · manual tool and cutter grinder

5 · bosch grinding machine 4 inch

6 · bosch grinder machine 4 inch

7 · accurate cutter grinding

Eliminate cooking by-products from the air with this stainless steel Whirlpool range hood. Its under-cabinet mounting style and FIT system makes .

ANCA is a global tier 1 supplier of CNC tool and cutter grinders with over 35 years experience and a reputation for flexible software and accurate machinesToday ANCA is a thriving business with over 1,000 employees and a world .Applications - The World's Most Flexible Tool Grinder - ANCA - CNC MachinesTechnology - The World's Most Flexible Tool Grinder - ANCA - CNC Machines

Shop - The World's Most Flexible Tool Grinder - ANCA - CNC MachinesNews - The World's Most Flexible Tool Grinder - ANCA - CNC Machines

WALTER provides cutting edge technology to the tool grinding machine market with an extensive product line that includes the HELITRONIC VISION tool grinder (featuring linear/torque motors in all axes) and HELITRONIC POWER .Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. With the HELITRONIC MINI PLUS tool grinding machine, tools with small and medium diameters can .

ANCA is a global tier 1 supplier of CNC tool and cutter grinders with over 35 years experience and a reputation for flexible software and accurate machinesWALTER provides cutting edge technology to the tool grinding machine market with an extensive product line that includes the HELITRONIC VISION tool grinder (featuring linear/torque motors in all axes) and HELITRONIC POWER universal CNC tool grinders.Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. With the HELITRONIC MINI PLUS tool grinding machine, tools with small and medium diameters can be flexibly produced and resharpened.

Star Cutter provides CNC Grinders for manufacturing and reconditioning of end mills, high-performance drills, drill points, step drills, form tools, medical tools, inserts, gear tools, and other custom tools.WIDMA manufactures cutting-edge CNC tool grinding machines for manufacturing & regrinding carbides and HSS tools. Used for regrind drills, end mills, reamers, etc.The TRU TECH line of centerless grinders provides precision surface grinding on cylindrical workpieces without the need for centers or chucks. Key to the TRU TECH grinders repeatability and consistency of closely held tolerances is the Perimetric 3-point work holding capability, enabled by the patented TT5000 and PP8000 Perimetric™ Grinding .

The TRU TECH grinding systems are recognized for ease of use and ultrafast set-up while delivering incredible accuracy and repetitive results. Featuring Perimetric grinding technology and CNC Pick-N-Place™ software, these machines are able to handle blank grinding through micro component applications for a variety of industries.Machine Control Technologies is committed to providing high-precision and cost effective CNC machines for the tool and cutter grinding industry. We custom-build every machine with personalized software and hardware so you have the exact machine you need to grind your tools with confidence and accuracy.

The is a five-axis CNC regrinding machine for hob and shaper cutters, configured with a direct drive single spindle operating at 11 kW peak power and motorized wheel dresser arrangement for profile dressing of grinding wheels. It also features an in-built hob inspection program.

Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. What is tool grinding? Tool grinding is a subset of the larger field of grinding. It involves a machining-based production process using abrasives or grinding wheels to produce or re-sharpen a workpiece.ANCA is a global tier 1 supplier of CNC tool and cutter grinders with over 35 years experience and a reputation for flexible software and accurate machinesWALTER provides cutting edge technology to the tool grinding machine market with an extensive product line that includes the HELITRONIC VISION tool grinder (featuring linear/torque motors in all axes) and HELITRONIC POWER universal CNC tool grinders.

walter tool and cutter grinder

Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. With the HELITRONIC MINI PLUS tool grinding machine, tools with small and medium diameters can be flexibly produced and resharpened.

Star Cutter provides CNC Grinders for manufacturing and reconditioning of end mills, high-performance drills, drill points, step drills, form tools, medical tools, inserts, gear tools, and other custom tools.WIDMA manufactures cutting-edge CNC tool grinding machines for manufacturing & regrinding carbides and HSS tools. Used for regrind drills, end mills, reamers, etc.The TRU TECH line of centerless grinders provides precision surface grinding on cylindrical workpieces without the need for centers or chucks. Key to the TRU TECH grinders repeatability and consistency of closely held tolerances is the Perimetric 3-point work holding capability, enabled by the patented TT5000 and PP8000 Perimetric™ Grinding .

The TRU TECH grinding systems are recognized for ease of use and ultrafast set-up while delivering incredible accuracy and repetitive results. Featuring Perimetric grinding technology and CNC Pick-N-Place™ software, these machines are able to handle blank grinding through micro component applications for a variety of industries.

Machine Control Technologies is committed to providing high-precision and cost effective CNC machines for the tool and cutter grinding industry. We custom-build every machine with personalized software and hardware so you have the exact machine you need to grind your tools with confidence and accuracy.The is a five-axis CNC regrinding machine for hob and shaper cutters, configured with a direct drive single spindle operating at 11 kW peak power and motorized wheel dresser arrangement for profile dressing of grinding wheels. It also features an in-built hob inspection program.

universal tool cutter grinder machine

$140.00

cnc cutter grinding machines|universal tool cutter grinder machine