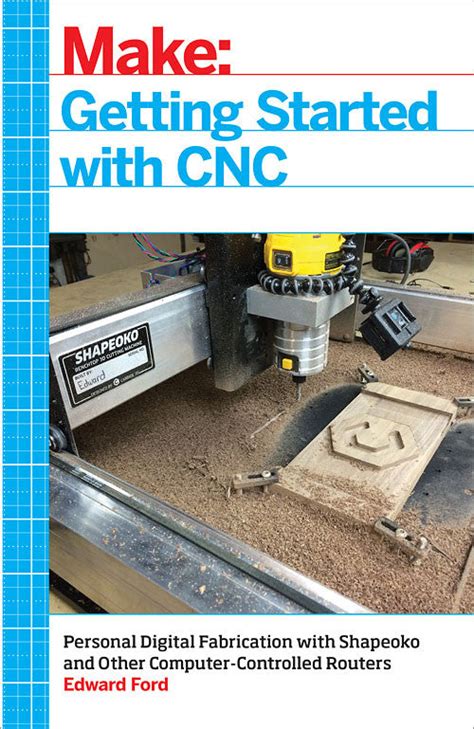

basic cnc machining This is a magazine that celebrates your right to tweak, hack, and bend any technology to your own will. "Big in Oversized Watches" is the motto of TW Steel. The range of different designs and styles is wide: Whether sporty, colourful or elegant, with leather, stainless steel, silicone or rubber bracelets: TW Steel watches are always a statement.

0 · make getting started with cnc

1 · cnc what you need toknow

2 · cnc machining for dummies

3 · cnc machining for beginners

4 · cnc machine a beginner's guide

5 · cnc basic knowledge

6 · basic knowledge of cnc machine

7 · basic cnc for beginners

Our main lines of business include: Air Conditioning Contractors, Heating Contractors. Turner Sheet Metal, Inc. has been listed in the Blue Book since 2012.

This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional .

This is a magazine that celebrates your right to tweak, hack, and bend any technology to your own will. What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC machining in 3. In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine.

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC .Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the . Here we’ll talk about the CNC basics for beginners covering FAQs like what machine you need to buy, what bits should you get, the definition and working of CNC system, and more. What is CNC and CNC System? To get started in CNC, you must understand the CNC Basics. This guide will help you find top CNC tutorials suitable for beginners. We’ll guide you on the critical concepts you need to learn and the sequence to follow.

This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive Rapid CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material. This is a magazine that celebrates your right to tweak, hack, and bend any technology to your own will.

What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC machining in 3. In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine.CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding.Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the Protolabs Network's Engineering Guide .

Here we’ll talk about the CNC basics for beginners covering FAQs like what machine you need to buy, what bits should you get, the definition and working of CNC system, and more. What is CNC and CNC System?

To get the best results, there is some basic knowledge you should focus your efforts on: 1. Knowing how to use a computer. A common requirement for all activities to be done with a CNC is knowing how to use a computer. To get started in CNC, you must understand the CNC Basics. This guide will help you find top CNC tutorials suitable for beginners. We’ll guide you on the critical concepts you need to learn and the sequence to follow.This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive Rapid

make getting started with cnc

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material. This is a magazine that celebrates your right to tweak, hack, and bend any technology to your own will.

What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC machining in 3.

In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine.CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding.Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the Protolabs Network's Engineering Guide .

Here we’ll talk about the CNC basics for beginners covering FAQs like what machine you need to buy, what bits should you get, the definition and working of CNC system, and more. What is CNC and CNC System?

cnc what you need toknow

junction box in attic ok

junction box installation method statement

cnc machining for dummies

Reliable milling spindles, powerful motors, innovative cooling systems and tool systems in all common sizes, including fast changers for the milling tools, are what characterize DMG MORI vertical machining centers – paired with the stable construction of the machines.

basic cnc machining|cnc what you need toknow