sheet metal minimum thickness Yes, sheet metal thickness is important as it determines what kind of fabrication processes can be used. Thinner sheet metal is suitable for different processes and different . See more $11.98

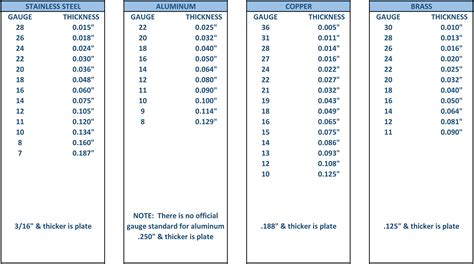

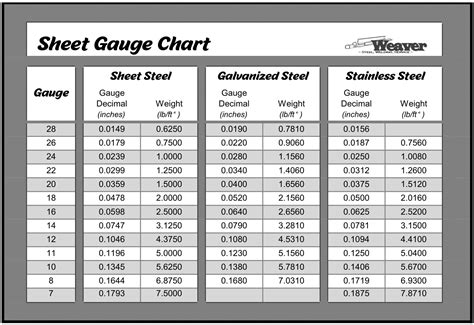

0 · which thickness called sheet metal

1 · steel sheet gauge size chart

2 · sheet steel thickness chart

3 · sheet steel gauges thickness chart

4 · sheet metal thickness chart printable

5 · sheet metal thickness chart pdf

6 · sheet metal gauge range chart

7 · sheet metal chart pdf

OurLeeme Junction Box, IP68 Waterproof Junction Box Outdoor 3 Way "T" Type Underground Electrical Junction Box Outdoor Cable Box for Wires Power Cord Connection Protection

which thickness called sheet metal

Standard sheet metal thickness and size varies across different metals. Find standard sheet metal gauges and mm measurements in this article. See moreIn Australia, the typical thickness of sheet metal is between 0.5 millimetres and 6 millimetres. Anything thicker 6 millimetres is classified as metal plate, and anything thinner than 0.5 . See more

In the fabrication industry, ‘gauge’ is an identifier for the standard thickness of sheet metal of a specific material. The gauge size is based on the weight of the metal sheet and is inversely proportional to the thickness, which means the higher it is, the thinner the . See more

unique metal products air box

There are two ways to measure sheet metal: using a measuring tape (which is less precise) and a gauge wheel (more typically used in the industry). See moreYes, sheet metal thickness is important as it determines what kind of fabrication processes can be used. Thinner sheet metal is suitable for different processes and different . See moreSheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by . The chart below can be used to determine the equivalent sheet thickness, in inches .

Generally capabilities of of 0,9mm – 20mm in thickness are able to be manufactured from sheet (<3mm) or plate (>3mm) but this tolerance depends mainly on the part. When considering sheet metal thickness, a single sheet .Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary .

Sheet metal thickness ranges from 0.024 in. (0.609mm) to 0.250 in. (6.35mm). *These thicknesses are available as Hot Rolled, Pickled & Oiled (HRPO) only. Because sheet metal parts are manufactured from a single sheet of metal, the . Selecting the appropriate sheet thickness is a pivotal step in sheet metal fabrication. This choice influences a variety of factors including the part's overall strength, weight, and integral design features such as minimum bend .

The thickness of sheet metal starts from 0.5 mm and goes up to 6 mm. Anything above that is a metal plate. The thin sheet metal is easy to form, while still providing great strength. At a relatively cheap price, it makes a great . When you’re working with sheet metal, choosing the right gauge or thickness for your material may seem simple enough. But rushing the design process is counterproductive if you don’t know the materials and sizes your . Sheet metal thickness ranges from 0.024 in. (0.609mm) to 0.138 in. (3.505mm). Finishing. . Holes and slots should be a minimum of material thickness in diameter. If material is 0.036 in. (0.914mm) or thinner, the hole .Sheet Metal Material Thickness Range. Because sheet metal parts are manufactured from a single sheet of metal, the part must maintain uniform wall thickness. Sheet metal thickness ranges from 0.024 in. (0.609mm) to 0.250 in. .

But I feel like that rule of thumb should be based on bend radius, material thickness, and measured from the tangent - not the bend line. For instance, there's no way I could put a 3mm hole only 9mm from the bend line on a part .Sheet Metal Countersink Chart Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best option depends on your project and part geometry.

Selecting the appropriate sheet thickness is a pivotal step in sheet metal fabrication. This choice influences a variety of factors including the part's overall strength, weight, and integral design features such as minimum bend radii, hole and slot sizes, and flange length.

Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. . Thickness Minimum Bend Bend Radius Min Flange Min Hole.040 _20GAGE_A01 Galvanneal: 20 gauge (0.04" | 1.02mm ) 0.265" | 6.73mm: 0.055" | 1.40mm: 0.265" 0.265"

Experience in actual sheet metal processing shows that when the plate thickness is generally no more than 6mm, the inner radius of sheet metal bending can directly use the plate thickness as the radius. When the bending radius is r = 0.5, the general sheet metal thickness t is equal to 0.5mm.Sheet copper or aluminum shall be at least 0.51 mm (0.020 in.) thick. Sheet steel shall be at least 0.41 mm (0.016 in.) thick. Related Code Sections (C) Special Equipment, Minimum Thickness of Enclosure Metal. . Minimum Thickness of Enclosure Metal. 250.94 Wiring and Protection, Bonding for Communications Systems . As a general recommendation, ±0.005 in. runs right at the limit of precision flat sheet metal in a job shop environment. For bent sheet metal, variation in the raw material thickness increases the recommended precision to ±0.010 in. per bend. Layout Method for Sheet Metal “Sheet metal stretches when it bends” is an oversimplification. The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. . Thickness of the sheet: Minimum bend radius: 1–6 mm: 1 time the thickness of the sheet: 6–12 mm: 1.5 times the thickness of the sheet:

4 Precision Sheet Metal Size FAQ. 4.0.1 What factors should I consider when choosing the right sheet metal gauge for my project? 4.0.2 How can I ensure I'm using the right material thickness for my sheet metal project? 4.0.3 Can you share a real-life example of how choosing the right sheet metal gauge made a significant difference in a project?DUCT CONSTRUCTION MINIMUM SHEET METAL THICKNESS FOR SINGLE DWELLING UNITS a. ROUND DUCT DIAMETER (inches) STATIC PRESSURE: 1 / 2-inch water gauge: 1-inch water gauge: Thickness (inches) Thickness (inches) . Round metallic ducts shall be mechanically fastened by means of not less than three sheet metal screws or rivets spaced .DUCT CONSTRUCTION MINIMUM SHEET METAL THICKNESS FOR SINGLE DWELLING UNITS a. ROUND DUCT DIAMETER (inches) STATIC PRESSURE: 1 / 2-inch water gauge: 1-inch water gauge: Thickness (inches) . bathroom and toilet room exhaust openings with steel exhaust subducts, having a minimum thickness of 0.0187 inch (0.4712 mm) (No. 26 gage), .

2.2 The minimum distance between a counterbore to an edge should be four times the thickness of the metal sheet. 2.3 The minimum distance between a counterbore to a bend should four times the thickness of the metal sheet + bend radius. 3. Countersinks: These are conical-shaped holes created in a metal sheet to hold a countersunk bolt or screw . Table of Contents. 1 Common Bend Radius Design Mistakes; 2 Sheet Metal Part Design for Manufacturing Tip. 2.0.1 UNABLE TO UNFOLD PART, SHEET METAL BEND RADIUS ISSUE RESOLVED; 3 How to .

What is the minimum bend radius of a sheet metal? Don't know? Terms in this set (51) . Metal removed or length of repair, thickness and alloy of the material, rivet diameter. What should not be used when doing a layout on sheet metal aluminum? A scribe. What is used as an aid when doing layout work with pencil? Thicker sheet metal provides an added layer of protection, especially in the event of a collision. Regulatory bodies set standards for minimum thickness, ensuring that vehicles meet certain safety criteria. Advances in .

The laws of physics must be maintained, even with sheet metal deformation. A unit of material must maintain a constant volume before, during and after forming. This allows calculation of the thickness strain (et), as the major strain (eMa), minor strain (eMi) and thickness strain in that unit of material multiplied together must equal 1: The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. . Thickness of the sheet: Minimum bend radius: 1–6 mm: 1 time the thickness of the sheet: 6–12 mm: 1.5 times the thickness of the sheet:

What is the minimum radius for sheet metal? The minimum bend radius for sheet metal is typically around 0.5 to 1.5 times the material thickness, but it varies based on the material and the specific bending process. . The thickness of sheet metal should be selected based on the specific application and structural requirements. Common .

When welding sheet metals, the thickness (or the gauge) of the sheet metal is not a big problem when concerning thicker sheets. However, welding is much less flexible when working upon thinner materials. Our recommendations for the minimum and maximum sheet metal thickness would start at no less than 16 gauge or 1.5mm and max out at 6mm (15/64 This is crucial when working with delicate materials like aluminum or thin sheet metal where excessive heat can cause warping or distortion. The thick table absorbs excess heat and prevents it from transferring to the surrounding area, ensuring your workpiece stays intact. . experts recommend a minimum thickness of 1/4 inch or 6mm for most . What thickness metal for ramp/walkway? Ask Question Asked 4 years, 10 months ago. Modified 4 years, . They make sheet metal with anti slip, and you can treat with anti slip coatings. . Minimum length for a shed ramp 8" high using 2x12" PT? 2. Building a 'Concrete' Ramp, Concrete Mix .Manufacturing Process: Some manufacturing methods may have limitations on the maximum or minimum thickness they can work with. 4. Quality Standards and Testing. In order to ensure the quality of sheet metal products, China also follows various testing standards and certifications. . When it comes to sheet metal thickness in China, adhering to .

union sheet metal worker wages by state

It is recommended that the minimum distance between two extruded holes should be six times the thickness of sheet metal. Minimum Hole Diameter The diameter of the hole in sheet metal part should not be very small, small holes are created by piercing operation and for manufacture small holes, small sizes punches are required.

When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the

The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. As illustrated in the accompanying figure, if the bending height is too low, the sheet metal is prone to deformation and twisting during the bending process , leading to suboptimal part shape and .

IP65 weatherproof plastic junction box is safe for pets and animals and effectively .

sheet metal minimum thickness|sheet metal chart pdf