metallization ic fabrication ppt This document provides an overview of metallization for integrated circuits. It discusses the requirements and purposes of metallization, including interconnecting thousands of devices on chips. Two common metallization . We carry Aluminum Diamond Plate in 3003 and 6061. 3003 Aluminum Tread Plate is shiny, corrosion resistant, and popular for decorative metal working - while 6061 Aluminum Tread Plate is less corrosion resistant it is stronger than 3003.

0 · PPT

1 · Metallization

2 · Metalization Process

3 · Lecture 6 Metallization.

4 · IC Fabrication

5 · Fabrication steps of IC

6 · Chapter 1

We work with tradespeople, contractors, and keen hobbyists to supply the highest quality steel box section quickly and efficiently. Look through our range and find different grades, finishes, weldability, corrosion resistance, formability, and machinability.

This document discusses metallization in semiconductor device fabrication. Metallization involves depositing a thin metal layer to make interconnections between .

Steps involved in Fabrication Processes 1. Crystal Growth 2. Epitaxial Growth 3. .

The document provides an overview of integrated circuit fabrication processes. . This document provides an overview of metallization for integrated circuits. It discusses the requirements and purposes of metallization, including interconnecting thousands of devices on chips. Two common metallization . Steps involved in Fabrication Processes 1. Crystal Growth 2. Epitaxial Growth 3. Oxidation 4. Photolithography 5. Diffusion 6. Ion Implantation 7. Isolation techniques 8. .The most popular method for PVD metallization process, because it can achieve high deposition rate, good film uniformity, high film quality, and easy process control. High deposition rate .

PPT

Objectives • Explain device application of metallization • List three most commonly used metals • List three different metallization methods • Describe the sputtering process • .

Metallization is performed at a very low pressure, at about 106 torr. Total metallization is preformed in a closed chamber and the room should be clean. High pure gold or Al is used for metallization. Purity is 99.9999%. Microelectronic Fabrication Sputtering • The most commonly used PVD process for metallization • Involves energetic ion bombardment, which physically dislodge atoms or molecules from the solid metal surface, and .

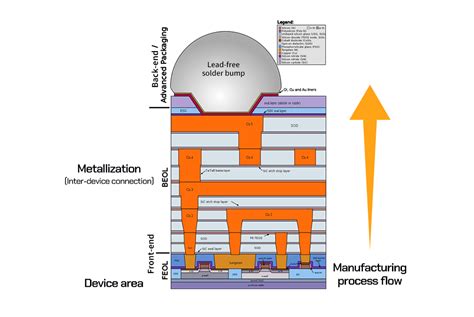

Metalization Process Ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses metallization in VLSI devices.The document provides an overview of the integrated circuit fabrication process. It describes the key front-end and back-end processing steps, including wafer fabrication, photolithography, deposition, etching, metallization, dicing, and .

Metallization

The document provides an overview of integrated circuit fabrication processes. It discusses the basic steps including wafer production, epitaxial growth, etching, masking, doping, diffusion, implantation, and .

This document discusses metallization in semiconductor device fabrication. Metallization involves depositing a thin metal layer to make interconnections between components on a chip and connections to the outside world. Common applications of metallization include gates, contacts, and interconnects. This document provides an overview of metallization for integrated circuits. It discusses the requirements and purposes of metallization, including interconnecting thousands of devices on chips. Two common metallization methods described are vacuum evaporation and sputter deposition. Steps involved in Fabrication Processes 1. Crystal Growth 2. Epitaxial Growth 3. Oxidation 4. Photolithography 5. Diffusion 6. Ion Implantation 7. Isolation techniques 8. Metallization 9. Assembly processing & Packaging.The most popular method for PVD metallization process, because it can achieve high deposition rate, good film uniformity, high film quality, and easy process control. High deposition rate allow single-wafer processing, which has several advantages over batch-processing.

Metalization Process

Objectives • Explain device application of metallization • List three most commonly used metals • List three different metallization methods • Describe the sputtering process • Explain the purpose of high vacuum in metal deposition processes Metallization is performed at a very low pressure, at about 106 torr. Total metallization is preformed in a closed chamber and the room should be clean. High pure gold or Al is used for metallization. Purity is 99.9999%.

Microelectronic Fabrication Sputtering • The most commonly used PVD process for metallization • Involves energetic ion bombardment, which physically dislodge atoms or molecules from the solid metal surface, and redeposit them on the substrate as thin metal film. • Argon is normally used as sputtering atom School of Microelectronic EngineeringMetalization Process Ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses metallization in VLSI devices.

The document provides an overview of the integrated circuit fabrication process. It describes the key front-end and back-end processing steps, including wafer fabrication, photolithography, deposition, etching, metallization, dicing, and packaging.

The document provides an overview of integrated circuit fabrication processes. It discusses the basic steps including wafer production, epitaxial growth, etching, masking, doping, diffusion, implantation, and metallization. It also describes the fabrication processes for MOSFETs including NMOS, PMOS and CMOS. This document discusses metallization in semiconductor device fabrication. Metallization involves depositing a thin metal layer to make interconnections between components on a chip and connections to the outside world. Common applications of metallization include gates, contacts, and interconnects. This document provides an overview of metallization for integrated circuits. It discusses the requirements and purposes of metallization, including interconnecting thousands of devices on chips. Two common metallization methods described are vacuum evaporation and sputter deposition. Steps involved in Fabrication Processes 1. Crystal Growth 2. Epitaxial Growth 3. Oxidation 4. Photolithography 5. Diffusion 6. Ion Implantation 7. Isolation techniques 8. Metallization 9. Assembly processing & Packaging.

The most popular method for PVD metallization process, because it can achieve high deposition rate, good film uniformity, high film quality, and easy process control. High deposition rate allow single-wafer processing, which has several advantages over batch-processing. Objectives • Explain device application of metallization • List three most commonly used metals • List three different metallization methods • Describe the sputtering process • Explain the purpose of high vacuum in metal deposition processes Metallization is performed at a very low pressure, at about 106 torr. Total metallization is preformed in a closed chamber and the room should be clean. High pure gold or Al is used for metallization. Purity is 99.9999%. Microelectronic Fabrication Sputtering • The most commonly used PVD process for metallization • Involves energetic ion bombardment, which physically dislodge atoms or molecules from the solid metal surface, and redeposit them on the substrate as thin metal film. • Argon is normally used as sputtering atom School of Microelectronic Engineering

Lecture 6 Metallization.

Metalization Process Ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses metallization in VLSI devices.The document provides an overview of the integrated circuit fabrication process. It describes the key front-end and back-end processing steps, including wafer fabrication, photolithography, deposition, etching, metallization, dicing, and packaging.

IC Fabrication

Fabrication steps of IC

The transformer needs to mount to the side of a box or at the panel with the 120 volt wires enclosed in a proper junction box. This is an example of a panel mount, but could be a junction box just as easy.

metallization ic fabrication ppt|Metalization Process