seal gap between two sheet metal parts Obrounds are common and can be a good choice if you’re trying to keep gaps to a minimum. For example a corner between two bends that you want to seal up after bending. An . $46.95

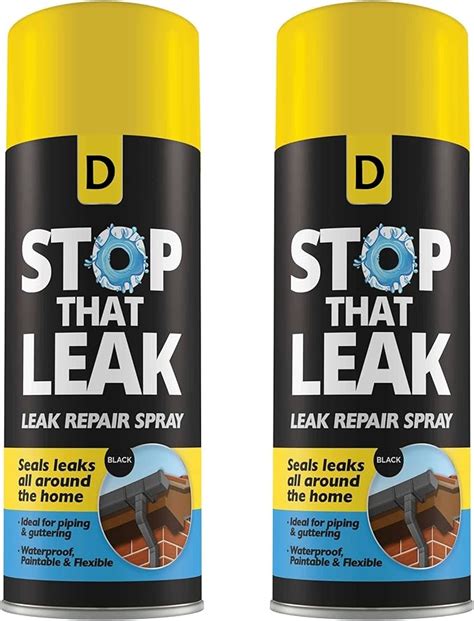

0 · Waterproof sealant for metal: Stops leaks in tough

1 · To Seal or Not to Seal: Metal Roof Repairs

2 · Sticking with Correct Sealant Application

3 · Sheet Metal Design Guidelines: How to Design Good Sheet Meta

4 · Seal Weld: Types, Benefits, and Best Practices

5 · Measuring a gap between two metal sheets

6 · LEAK

7 · Is it possible to make a watertight seal between two

8 · How to Seal Between Metal Roofing Sheets

9 · How to Design Bend Reliefs & Corner Reliefs for Sheet Metal Parts

10 · Caulk and Sealant Guide

$1,451.43

Waterproof sealant for metal: Stops leaks in tough

jack in the box song metal

Waterproof sealant for metal adheres upon contact with metal surfaces, closing the gap on seams, joints, and around fasteners. SMP (silane-modified polymers) sealants, for instance, form a waterproof bond and can be applied on wet . Since metal substrates expand and contract with changes in temperature, sealants (they consist of polymers that allow flexibility) aid metal . Obrounds are common and can be a good choice if you’re trying to keep gaps to a minimum. For example a corner between two bends that you want to seal up after bending. An .A gasket is a material positioned between two flanges which are held together by fasteners. Gaskets prevent leaking of fluids or gases by completely filling the space between the surfaces .

Seal welds seal gaps between metal components, ensuring no gases or fluids can escape. This technique involves creating an uninterrupted weld at the joint. The edges are often overlapped to ensure complete coverage.

Metal-metal seals can be gas tight, not just watertight. It just needs to be firmly seated all the way around, with a bit of compression. If it fits too well it'll be hard to open, though. Something like a hemispherical stopper pressed into a conical . How to Seal Between Metal Roofing Sheets. Water penetration can cost homeowners big bucks when the seams of metal roofing sheets have not been sealed . When it comes to metal roof repairs, the question we’re always asked is whether or not to seal the gaps where the sheets overlap. There are arguments for and against sealing a metal roof, so let’s take a closer look at .During assembly, it is frequently necessary to align two metal sheets as close as possible in the joining process in order to guarantee a good weld seam. The aim of the application is to determine the gap between two metal sheets and to .

Bellow seals are a type of mechanical seal that use thin sheets of metal in the shape of a bellow to create a seal between a shaft and a hollow tube or cylinder [19]. Bellow seals are typically used in harsh conditions such as .

Metal-metal seals can be gas tight, not just watertight. It just needs to be firmly seated all the way around, with a bit of compression. . As copper is soft (relatively, still a very strong material) it gets compressed and fills in the gaps .The aim of the application is to determine the gap between two metal sheets and to transfer the measured value to the control system. The challenge here lies in the surface of the objects, which are often contaminated with oil stains, dirt or .Much like the liquid shim, classic bondo can be used too if the vibration and flexing levels between the parts is low. Another option, and I can't come up with the name of them, is a piece of sheet metal to the small clearance thickness, corrugated on one edge, and rolled into a tube to fit between the two parts.

To Seal or Not to Seal: Metal Roof Repairs

Sheet metal parts are known for their durability, which makes them great for end use applications (e.g. chassis). . Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it can lead to metal deformation. . This ‘gap’ is known as the laser kerf and ranges from 0.08 – 0 . Windshield seal gap. Jump to Latest . the roof had oil canning that was repaired by adding a bead rolled sheet metal stiffener under the headliner. The glass shop is 100% wrong about the truck being tweaked but arguing with them is like carrying on an argument with a cat. . Wet between the glass and seal and the truck and the seal use .ALL posts related to SOLIDWORKS are welcome. Share what you know. Learn what you don't. 100% Pirate Free Sub. Zero ToleranceHow do you seal a gap between French doors? Close the gap between the two doors with insulated molding. Nail it to one of the doors using small wood nails so that it overlaps the other door by about one-half inch, covering the gap. Place nails about every 5 inches. Cover the nail heads with wood putty and sand them smooth. 👉 www.hunker.com.

Caulks and sealants are used in metal construction to fill gaps and cracks. They are a barrier to prevent the passage of air, water, moisture, gas, noise, dust and smoke. Generally representing less than 1 percent of a building's cost, they are extremely important to the water/airtightness of the building. For this reason, correct selection based on properties and .

The two 16'x8' sides have four 4' x 8' plywood sheets running horizontally i.e one 4'x8' sheet is on top of another 4' x 8' sheet. Next to these two sheets are two other sheets with one 4'x8' sheet being on top of another 4' x 8' sheet. On the back there are two 4' x 8' sheets, one sheet being on top of another i.e. they are attached horizontally. I'd recommend a sheet metal screw or two where the two pieces of metal do overlap, just to be sure gravity doesn't work against you over time, then a layer or two of duct tape to cover the gap and metal on both sides of it. Use the proper silver foil & plastic stuff available in the HVAC aisle at a hardware store, not "duck tape" available in .

Hello, I have a metal building with a gap around the entire base where the building meets concrete slab. I would like to seal it on the outside and inside to prevent air and insects from entering. I am not very knowledgeable with home improvements. Any suggestions would be greatly appreciated! You can easily close this gap, or gaps at any of the corners, so the seal lip covers the gap. There is enough overlap in the channel of the seal where it wraps around the glass to accommodate this process. I usually use a piece of wooden shim material like you can get at any hardware store, used for framing up doors and windows.Wondering if I can have two very flat + high surface finish quality metal parts mate with each other and create an airtight seal. No crazy pressures, just 5psi. Is there any way I could calculate it or verify this? By first principles, the size of an air molecule makes me thing CNC tolerances (+/-0.025mm) cannot achieve an airtight seal Use same materials for the seal flanges Try to achieve uniform temperature distribution 3.3 FLANGE RIGIDITY1 The operational safety of a gasketed joint can be strongly influenced by varying the flange rigidity. The compressive stress distribution in the seal gap and in the flange between bolt head and seal gap indicates the rigidity of the joint.

Metal inert gas (MIG) welding is an arc welding method typically used on large parts m a d e of thick material, such as structural steel parts. With this method, we feed a continuous solid wire electrode through a we lding gun into a weld pool to join two pieces together.. Considerations for MIG welding In a flat or closed hem, the part of the edge that bends sits completely flush over the rest of the metal sheet. The angle between the returning flange and the sheet metal is 180 degrees. The inside radius is zero and thus, there is no .

how to seal gap between roof and gutter seal gap between door and frame. Ask Question Asked 5 years, 8 months ago. Modified 5 years, 8 months ago. Viewed 105 times . Use some sheet metal, rats can and will chew through wood, plastic and foam very easily. Especially if they are already established in the shed. You can bend the sheet metal over and fasten it from both sides. The filler metal is never as strong as the base metals. It is meant to fuse two pieces of metal together into one solid piece. When there’s a small seam to fill, it requires very little of the weaker filler metal, so as long as you penetrate into it, the job can handle the stress with the strength of the base metals. . Sheet Metal Gap . 4*UL I made my own sheet metal styles and I still can't change the default corner size. If I start with a sheet and bend all 4 corners at the same time I can get the correct results. If I have a part with a couple falnges on it already it doesn't make a nice corner. Instead it makes a gap that is much too big to fuse with a TIG welder.

Because the water is held in place within the gap, those exposed parts of the metal sheet never dry out completely, which has the potential to create serious damage over time. Eventually, the zinc layer on the reverse side of the sheet becomes eroded, potentially allowing the ingress of water into the building, compromising the roof’s integrity. The gap on the far side was so big that I dropped the other half of my half moon sheet metal piece down the gaping hole, never to be seen again (you can see it in pic #3 at the bottom of the hole). I ended up taking a flat sheet of 14" wide sheet metal and laying it over the gap butted up against the flue after trimming a rough circle in it.The system can seal against either a flat metal surface or another seal of the same design. This sealing system has been designed to accommodate multiple sealing cycles and has exhibited extremely low leak rates, making it an attractive solution within a variety of industries from aerospace to agriculture.Manufacturing sheet metal parts can be particularly difficult. The production cost per component is very low compared with other industries such as metal machining. . dropped on day two and then used for the rest of the year while out of calibration without any means to detect the problem. For reasons such as this, CMMs are usually placed in .

$34.99

seal gap between two sheet metal parts|Waterproof sealant for metal: Stops leaks in tough