cnc machine applications CNC Router machines can cut complex shapes, and their applications involve carved wood furniture, moldings, interior and exterior decorations, door carvings, signage, musical instruments, and so on. They .

Shop Space Solutions 18" 2 Drawer Mobile Smart Vertical File Cabinet Pearl White at Best Buy. Find low everyday prices and buy online for delivery or in-store pick-up. . Yes, this cabinet comes fully assembled. Handles and casters .

0 · products made by milling machine

1 · industries that use cnc machines

2 · cnc milling application

3 · cnc machine work needed

4 · cnc machine and fabrication

5 · cnc controlled machines

6 · application of cnc lathe machine

7 · all types of cnc machines

Our Vertical Sheet Metal Racks are an ideal choice to address the challenges of storing metal sheets. Whether you need to store steel sheets, aluminum sheets, or other metal materials, we provide an efficient solution to enhance your production efficiency and warehouse management effectiveness.

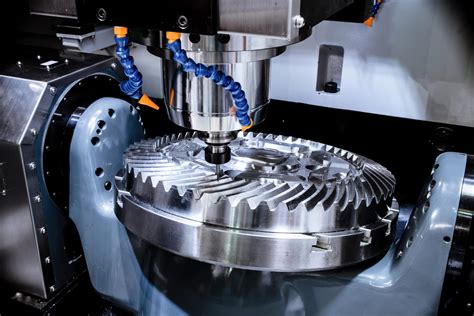

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

CNC stands for Computer Numerical Control. The CNC machining process is a manufacturing process that creates the final part by removing material using a cutting tool. . Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC .

CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. .

CNC machines are typically designed with protective structures, reducing operator contact with the machines and lowering workplace safety risks. Operators can monitor the machining . CNC Router machines can cut complex shapes, and their applications involve carved wood furniture, moldings, interior and exterior decorations, door carvings, signage, musical instruments, and so on. They . Computer numerical control (CNC) machining has been a staple process in manufacturing. CNC technology combines computer programming and mechanical machining to produce various products, from everyday items to .Discover the CNC milling process, from initial CAD design to the final product, and its vital applications in diverse industries. What is CNC milling? A complete guide on processes, applications, benefits, and limitations.

Let’s navigate through the different types of CNC machining and uncover the unique attributes and applications of each. Milling: Milling machines use rotary cutters to remove material. They’re versatile and can produce everything from . Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

Typical applications for CNC machining include fabricating, ornamental furniture, and turbine blades. The cost of CNC machining depends heavily on the required precision, surface quality, quantity, material used, and overall part complexity.

products made by milling machine

industries that use cnc machines

cnc machine fabrication near me

CNC stands for Computer Numerical Control. The CNC machining process is a manufacturing process that creates the final part by removing material using a cutting tool. There are many different types of CNC machines with numerous cutting tool options for a range of jobs and applications. Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them.CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling)

CNC machines are typically designed with protective structures, reducing operator contact with the machines and lowering workplace safety risks. Operators can monitor the machining process within a safe distance, avoiding direct contact with sharp tools and harmful coolants. CNC Router machines can cut complex shapes, and their applications involve carved wood furniture, moldings, interior and exterior decorations, door carvings, signage, musical instruments, and so on. They decrease waste, improve . Computer numerical control (CNC) machining has been a staple process in manufacturing. CNC technology combines computer programming and mechanical machining to produce various products, from everyday items to complex parts. Let's explore its CNC machining capabilities and applications in multiple industries. What Are CNC Capabilities?

Discover the CNC milling process, from initial CAD design to the final product, and its vital applications in diverse industries. What is CNC milling? A complete guide on processes, applications, benefits, and limitations.Let’s navigate through the different types of CNC machining and uncover the unique attributes and applications of each. Milling: Milling machines use rotary cutters to remove material. They’re versatile and can produce everything from simple shapes to complex geometries.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

Typical applications for CNC machining include fabricating, ornamental furniture, and turbine blades. The cost of CNC machining depends heavily on the required precision, surface quality, quantity, material used, and overall part complexity. CNC stands for Computer Numerical Control. The CNC machining process is a manufacturing process that creates the final part by removing material using a cutting tool. There are many different types of CNC machines with numerous cutting tool options for a range of jobs and applications. Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them.

CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling)CNC machines are typically designed with protective structures, reducing operator contact with the machines and lowering workplace safety risks. Operators can monitor the machining process within a safe distance, avoiding direct contact with sharp tools and harmful coolants. CNC Router machines can cut complex shapes, and their applications involve carved wood furniture, moldings, interior and exterior decorations, door carvings, signage, musical instruments, and so on. They decrease waste, improve . Computer numerical control (CNC) machining has been a staple process in manufacturing. CNC technology combines computer programming and mechanical machining to produce various products, from everyday items to complex parts. Let's explore its CNC machining capabilities and applications in multiple industries. What Are CNC Capabilities?

Discover the CNC milling process, from initial CAD design to the final product, and its vital applications in diverse industries. What is CNC milling? A complete guide on processes, applications, benefits, and limitations.

cnc machine for cutting eva foam

cnc milling application

$170.90

cnc machine applications|products made by milling machine