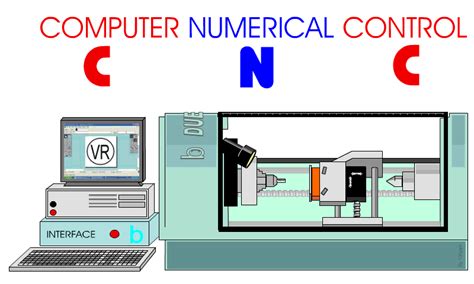

cnc machine introduction What is a CNC Machine? A Computerized Numerical Control (CNC) Machine is a device used by machinists to create high-precision parts from a variety of metals. These machines have 1 or more functions, such as drilling, .

Call 1-800-292-0111 for details and building plans. Used Metal Buildings for Sale by Owner - Browse 100's of Used Metal Buildings and Steel Building Kits for Sale in Your State, or List Your Building with Us!

0 · introduction to computer numerical control

1 · introduction to cnc machine pdf

2 · how to cnc machining work

3 · how cnc machine is controlled

4 · cnc machine used for

5 · cnc machine stand for

6 · cnc machine operation basics

7 · cnc machine block diagram

$118.03

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the .

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed . CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product.

CNC (Computer Numerical Control) machines are automated tools controlled by computers to execute precise machining operations. These represent a revolutionary advancement in the realm of manufacturing and .

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to . What is a CNC Machine? A Computerized Numerical Control (CNC) Machine is a device used by machinists to create high-precision parts from a variety of metals. These machines have 1 or more functions, such as drilling, .CNC machining is the most common subtractive manufacturing technology today and a hugely flexible and robust way to produce custom metal and plastic parts. Using CAD models, CNC machines precisely remove material from a solid .CNC, or Computer Numerical Control, is a method where digital instructions control the movement of tools across two to five axes, allowing precise and automated operations.

To get the best results, there is some basic knowledge you should focus your efforts on: 1. Knowing how to use a computer. A common requirement for all activities to be done with a CNC is knowing how to use a computer. What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process.

introduction to computer numerical control

introduction to cnc machine pdf

metal boxes botw

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding. CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product. CNC (Computer Numerical Control) machines are automated tools controlled by computers to execute precise machining operations. These represent a revolutionary advancement in the realm of manufacturing and automation.

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material. What is a CNC Machine? A Computerized Numerical Control (CNC) Machine is a device used by machinists to create high-precision parts from a variety of metals. These machines have 1 or more functions, such as drilling, milling, lathing, routing, engraving and surface finishing.CNC machining is the most common subtractive manufacturing technology today and a hugely flexible and robust way to produce custom metal and plastic parts. Using CAD models, CNC machines precisely remove material from a solid block with a variety of cutting tools.

CNC, or Computer Numerical Control, is a method where digital instructions control the movement of tools across two to five axes, allowing precise and automated operations. To get the best results, there is some basic knowledge you should focus your efforts on: 1. Knowing how to use a computer. A common requirement for all activities to be done with a CNC is knowing how to use a computer.

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process.CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding. CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product.

CNC (Computer Numerical Control) machines are automated tools controlled by computers to execute precise machining operations. These represent a revolutionary advancement in the realm of manufacturing and automation. CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material. What is a CNC Machine? A Computerized Numerical Control (CNC) Machine is a device used by machinists to create high-precision parts from a variety of metals. These machines have 1 or more functions, such as drilling, milling, lathing, routing, engraving and surface finishing.CNC machining is the most common subtractive manufacturing technology today and a hugely flexible and robust way to produce custom metal and plastic parts. Using CAD models, CNC machines precisely remove material from a solid block with a variety of cutting tools.

CNC, or Computer Numerical Control, is a method where digital instructions control the movement of tools across two to five axes, allowing precise and automated operations.

metal boxes for icf walls

how to cnc machining work

We have a wide variety of metal storage cabinets to provide the ultimate organizing options for your business. Feel free to browse our metal storage cabinets or come by our store today!

cnc machine introduction|introduction to cnc machine pdf