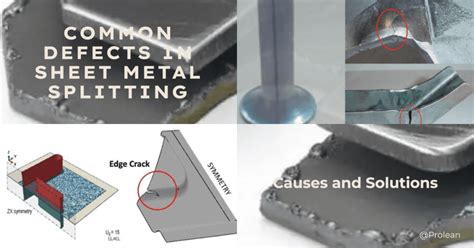

defects in sheet metal parts Having incorporated that glass-half-full mindset, let’s identify some common sheet metal defects. Sheet Metal Splits. A series of wrinkles is growing and propagating. The layers of metal are . Work, yes, but there are drawbacks (that most likely don't matter). The thread pitch is likely smaller and the tooth shape may be different as well, so the holding strength may be slightly reduced/more prone to stripping.

0 · wrinkle defect in sheet metal

1 · types of sheet metal defects

2 · steel lamination defect pictures

3 · sheet metal rolling defects

4 · sheet metal defects pdf

5 · scoring marks in sheet metal

6 · defects in sheet metal operation

7 · defects in sheet metal forming

Wil-Clair Sheet Metal located at 318 E 16th Ave, Kansas City, MO 64116 - reviews, ratings, hours, phone number, directions, and more.

2. Bending Defects: Springback, Wrinkling, and Cracking Defects and Causes. Springback: The elastic recovery of metal after bending, leading to inaccurate angles. Wrinkling: Excessive compression on the inner bend radius due to inadequate die design or force application. . Sheet Metal Deep-Drawing Defects. Earing, wrinkling, and material tearing are the major sheet metal defects associated with the deep-drawing process. The earring defect refers .

Defects in sheet metal processing can lead to costly errors and compromise the quality of your final product. However, by identifying common issues such as warping, .Having incorporated that glass-half-full mindset, let’s identify some common sheet metal defects. Sheet Metal Splits. A series of wrinkles is growing and propagating. The layers of metal are .Wrinkles, splits, and springback are the three most common defects encountered during sheet metal stamping. Generally, if experiencing wrinkles during production, this could mean the wrong process was chosen to manufacture . Part II of this series about sheet metal defects focuses on the common problems that can be caused during various stages of the material's production.

wrinkle defect in sheet metal

We will show you which defects can occur in sheet metal and how they can be eliminated. As soon as the sheets leave the rolling mill, the most common coil defect is already foreseeable: .

2-door 5 shelve steel cabinet

To figure this out, you need to know what you are getting and where the numbers come from when troubleshooting is done. To get started, we’ve got to use the same terms. Whether it’s steel or aluminum, it’s melted in .During sheet metal bending, various defects arise due to factors such as raw material characteristics, part properties, and operational processes. Common defects in sheet metal .

2. Bending Defects: Springback, Wrinkling, and Cracking Defects and Causes. Springback: The elastic recovery of metal after bending, leading to inaccurate angles. Wrinkling: Excessive compression on the inner bend radius due to inadequate die design or force application. Cracking: Fractures along the outer bend radius caused by insufficient material ductility or a sharp bend . Sheet Metal Deep-Drawing Defects. Earing, wrinkling, and material tearing are the major sheet metal defects associated with the deep-drawing process. The earring defect refers to an uneven height around the rim of the drawn part. The main reason is neglecting the work and die materials compatibility. 5 Tips to Avoid Typical Sheet Metal Defects Sheet metal defects affect the appearance, function or structural integrity of the sheet metal. Learn the defects and avoid them in the sheet metal process.

Defects in sheet metal processing can lead to costly errors and compromise the quality of your final product. However, by identifying common issues such as warping, cracking, and surface imperfections, manufacturers can take proactive steps to prevent these problems.Having incorporated that glass-half-full mindset, let’s identify some common sheet metal defects. Sheet Metal Splits. A series of wrinkles is growing and propagating. The layers of metal are being pushed past their workability limits, to the point the sheet metal is beginning to thin.Wrinkles, splits, and springback are the three most common defects encountered during sheet metal stamping. Generally, if experiencing wrinkles during production, this could mean the wrong process was chosen to manufacture the part or a key process parameter (such as binder force) could be incorrect. Part II of this series about sheet metal defects focuses on the common problems that can be caused during various stages of the material's production.

We will show you which defects can occur in sheet metal and how they can be eliminated. As soon as the sheets leave the rolling mill, the most common coil defect is already foreseeable: coil curvature. To figure this out, you need to know what you are getting and where the numbers come from when troubleshooting is done. To get started, we’ve got to use the same terms. Whether it’s steel or aluminum, it’s melted in a furnace one batch at a time. Each batch of liquid metal is called a heat.During sheet metal bending, various defects arise due to factors such as raw material characteristics, part properties, and operational processes. Common defects in sheet metal bending forming processes include noticeable issues like bending springback, bending cracks, and bending indentations.

2. Bending Defects: Springback, Wrinkling, and Cracking Defects and Causes. Springback: The elastic recovery of metal after bending, leading to inaccurate angles. Wrinkling: Excessive compression on the inner bend radius due to inadequate die design or force application. Cracking: Fractures along the outer bend radius caused by insufficient material ductility or a sharp bend . Sheet Metal Deep-Drawing Defects. Earing, wrinkling, and material tearing are the major sheet metal defects associated with the deep-drawing process. The earring defect refers to an uneven height around the rim of the drawn part. The main reason is neglecting the work and die materials compatibility. 5 Tips to Avoid Typical Sheet Metal Defects

Sheet metal defects affect the appearance, function or structural integrity of the sheet metal. Learn the defects and avoid them in the sheet metal process. Defects in sheet metal processing can lead to costly errors and compromise the quality of your final product. However, by identifying common issues such as warping, cracking, and surface imperfections, manufacturers can take proactive steps to prevent these problems.Having incorporated that glass-half-full mindset, let’s identify some common sheet metal defects. Sheet Metal Splits. A series of wrinkles is growing and propagating. The layers of metal are being pushed past their workability limits, to the point the sheet metal is beginning to thin.Wrinkles, splits, and springback are the three most common defects encountered during sheet metal stamping. Generally, if experiencing wrinkles during production, this could mean the wrong process was chosen to manufacture the part or a key process parameter (such as binder force) could be incorrect.

Part II of this series about sheet metal defects focuses on the common problems that can be caused during various stages of the material's production.We will show you which defects can occur in sheet metal and how they can be eliminated. As soon as the sheets leave the rolling mill, the most common coil defect is already foreseeable: coil curvature.

To figure this out, you need to know what you are getting and where the numbers come from when troubleshooting is done. To get started, we’ve got to use the same terms. Whether it’s steel or aluminum, it’s melted in a furnace one batch at a time. Each batch of liquid metal is called a heat.

By storing your car keys, fob or card in an aluminum tin (even grandma’s old biscuit tins), or a special signal blocking box, the signal between the car and key will probably be blocked. This means thieves can’t intercept it and clone a new fob to steal your vehicle.

defects in sheet metal parts|sheet metal rolling defects