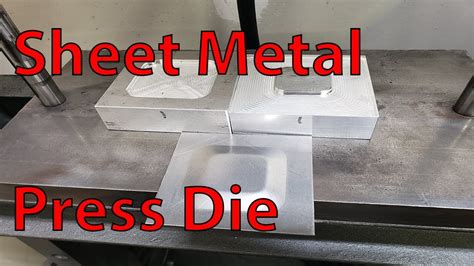

draw forming sheet metal Deep drawing is a stamping and forming process in which a flat sheet is formed into an open hollow part through a concave die under pressure of a convex die. In all types of . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

0 · sheet metal forming press dies

1 · sheet metal forming by hand

2 · mechanics of sheet metal forming

3 · forming stainless steel sheet metal

4 · forming aluminum sheet by hand

5 · forming 2x22 steel

6 · deep drawing of sheet metal

7 · custom sheet metal forming

It is better to avoid using a flux-cored wire when welding sheet metals. It will make the base metal more susceptible to heat. The best two electrodes for welding auto body sheet metal are either ceriated tungsten or thoriated tungsten.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different . Deep drawing, at its essence, is a sheet metal forming process where the metal sheet is radially drawn into a forming die by the mechanical action of a punch. The depth of the formed part can be greater than its .

These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels . Deep drawing is a stamping and forming process in which a flat sheet is formed into an open hollow part through a concave die under pressure of a convex die. In all types of .

Creating a hem in sheet metal requires special tooling and machinery, often involving press brakes or other sheet metal forming equipment. Proper design and execution of hems is essential to ensure they don't split or deform during .Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking.

.describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects . Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a .

Deep drawing, at its essence, is a sheet metal forming process where the metal sheet is radially drawn into a forming die by the mechanical action of a punch. The depth of the formed part can be greater than its diameter, which is what differentiates deep drawing from other standard drawing processes.

These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Deep drawing is a stamping and forming process in which a flat sheet is formed into an open hollow part through a concave die under pressure of a convex die. In all types of sheet metal components, deep drawing is often used for the processing of various cylindrical parts, hemispheres and parabolic heads of larger size or thicker material.Creating a hem in sheet metal requires special tooling and machinery, often involving press brakes or other sheet metal forming equipment. Proper design and execution of hems is essential to ensure they don't split or deform during the bending process.Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking.

.describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges Objectives

cnc turning milling grinding parts factory

sheet metal forming press dies

To illustrate the principles of metal flow, this article examines two basic draw shapes, round and square. All deformation modes that occur in any given part shape are present in one of these common shapes. The draw ratio is among the most important elements to be considered when attempting to deep draw a round cup.Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius.

Deep drawing is a sheet metal forming process used when the depth of a part exceeds its diameter. This process allows manufacturers to form complex, hollow shapes, such as cups or cylinders, from flat metal sheets. Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a . Deep drawing, at its essence, is a sheet metal forming process where the metal sheet is radially drawn into a forming die by the mechanical action of a punch. The depth of the formed part can be greater than its diameter, which is what differentiates deep drawing from other standard drawing processes.

These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.

Deep drawing is a stamping and forming process in which a flat sheet is formed into an open hollow part through a concave die under pressure of a convex die. In all types of sheet metal components, deep drawing is often used for the processing of various cylindrical parts, hemispheres and parabolic heads of larger size or thicker material.Creating a hem in sheet metal requires special tooling and machinery, often involving press brakes or other sheet metal forming equipment. Proper design and execution of hems is essential to ensure they don't split or deform during the bending process.Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking.

.describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges Objectives To illustrate the principles of metal flow, this article examines two basic draw shapes, round and square. All deformation modes that occur in any given part shape are present in one of these common shapes. The draw ratio is among the most important elements to be considered when attempting to deep draw a round cup.

Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius.

sheet metal forming by hand

cnc turret parts

Pull the wires you need to connect into the electrical junction boxes through the holes you’ve made. Allow six inches of wire to hang out of the box and then cut off any excess wire with your knife. You want ample wire so you can work easily, but not an excess.A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

draw forming sheet metal|sheet metal forming by hand