cnc machine tooling iot IoT plays a crucial role in modern CNC machining by enabling digital connectivity and data analytics. Through IoT, CNC machines can collect, transmit, and analyze data in real-time, providing insights into machine . Steel and stainless steel louvers providing 80% and 100% direct visual screening. Perfect for equipment and trash enclosures, roof top screening and parking garages.

0 · iot integration in manufacturing

1 · iot in cnc machinery

2 · iot impact on cnc

3 · iot cnc industry

4 · integration of iot and cnc

5 · connected machining iot

6 · cnc technology industry

7 · cnc machine learning

95 talking about this

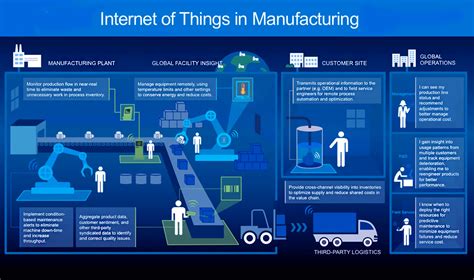

Below, we’ll explore the role of IoT in CNC machining and how companies can take advantage of this technology to realize superior production results and perhaps even a path to .IoT-driven CNC machines streamline the manufacturing process, leading to a significant uptick in productivity. With real-time monitoring, these machines can operate at optimal speeds, manage resources more efficiently, and reduce the . IoT plays a crucial role in modern CNC machining by enabling digital connectivity and data analytics. Through IoT, CNC machines can collect, transmit, and analyze data in real-time, providing insights into machine . IoT-enabled CNC machines can now communicate with other machines and systems, allowing for automated adjustments and more .

IoT's integration into CNC machines promises unprecedented levels of efficiency and precision, reshaping traditional manufacturing processes. This article delves into how IoT elevates CNC technology, detailing its .Integrating IoT technologies into CNC machines is revolutionizing the industry with improved product quality, reduced costs, and enhanced productivity. Here are some key advancements: RFID Advancements: Radio Frequency .CNC machines, equipped with smart technology and embedded sensors, harness the power of IoT by sharing real-time data about machine performance, work schedules, tooling condition, material status, and much more.Get up-to-speed on IoT in CNC manufacturing. CNC Cookbook has expert insights on what you need to know to stay ahead of the game.

IoT integration allows CNC machines to seamlessly connect with enterprise resource planning (ERP) systems, inventory management software, and other business .Contact Info. Kiseki Machinery - High Tech CNC Machine Tool Supplier #1992, J- Block, 3rd Street, Annanagar, Chennai, Tamilnadu, India. Pin 600040By equipping CNC machines, tools, and production lines with IoT sensors, manufacturers gain real-time insights into every aspect of the manufacturing process. This visibility enables the optimization of workflows, the reduction of . The integration of Internet of Things (IoT) technology into CNC gear slotting machines represents a significant leap forward in modern manufacturing. This advancement brings about enhanced connectivity, predictive maintenance, real-time data monitoring, remote diagnostics, and improved overall efficiency and productivity.

Here, data collection and monitoring are an important part of intelligent manufacturing workshops. As modern automation and computer technology advance, the shortcomings of the older version of the CNC system become more apparent. This study presents a remote monitoring and management system for CNC machine tools using the Internet of . Verisurf’s Machine Tool Probing (MTP) suite is an in-process automated inspection solution for CNC machine tools, offering inspection and reporting capabilities. 29 Oct 2024 Cutting . Bain & Co. research indicates that the industrial portion of the Internet of Things (IIoT)—including software, hardware and system solutions in the .

A CNC machine is a crucial piece of equipment used in the modern manufacturing industry. . Smart manufacturing is associated with the Internet of Things . and S.-H. Ahn, A low-cost vision-based monitoring of computer numerical control (CNC) machine tools for small and medium-sized enterprises (SMEs), Sensors 19(20);2019:4506 [Online .M2M: Refers to Machine-To-Machine, which is what happens when machines use IoT to talk to each other. MTConnect: The most prevalent standard for CNC (and other Shop Floor) machines to communicate with IoT. OPC-UA: It’s a standard like MTConnect, but rather than being focused on machine tools, OPC-UA is about plant-wide communications.CNC machining; Business strategies for manufacturers; Industry news and updates; 3. IoT Podcast. Hosts: Stacey Higginbotham and Kevin Tofel Overview: This podcast explores the latest developments in the Internet of Things (IoT), discussing how these technologies are being integrated into various industries, including manufacturing. Focus Areas .CNC machine monitoring solution is a perfect example that shows the capability of IoT based CNC solutions. Biz4Intellia is an end to end IoT solution providing companies that help factories and workshops to integrate their CNC machines with IoT solutions. Request a demo today to see how you can use IoT in your factory setting.

8. CNC Machine Tools Market Segmentation, By Product Type 9. CNC Machine Tools Market Segmentation, By Industry Segment 10. Regional Analysis 11. Company Profile 12. Use Cases and Best Practices . Meta Title: Future of CNC Machines: AI, IoT & Industry 4.0. [email protected] Seasonal Sale! Enjoy 10% off on all machines, Request FREE Quote! Search for: Get Quote Now. Close; . AI enhances CNC machine operations by optimizing tool paths, predicting maintenance needs, and improving decision-making processes. For . CNC (Computer Numerical Control) machines are automated systems used in manufacturing for precisely controlling machining tools using computer programming. They are critical in industries such as aerospace, automotive, and metallurgy, where precision, consistency, and efficiency are required.

Advances like IoT and 5G will further upgrade CNC programming, adapting to new manufacturing methods like 3D printing. Thus, CNC manual programming is unlikely to become obsolete soon but will continue to evolve and remain essential. . Systems & Components (Parts) of CNC Machine What is Tool Setter – CNC Tool Setter Types, Cost, Work . IntroductionThe fourth industrial revolution, or Industry 4.0, is reshaping manufacturing with advancements in automation, data exchange, and real-time processing. Key technologies like the Internet of Things (IoT), cloud computing, and Artificial Intelligence (AI) are at the forefront, driving efficiencies and innovations previously unattainable. In this post, we .Integrating IoT technologies into CNC machines is revolutionizing the industry with improved product quality, reduced costs, and enhanced productivity. Here are some key advancements: RFID Advancements : Radio Frequency .

Contact Info. Kiseki Machinery - High Tech CNC Machine Tool Supplier #1992, J- Block, 3rd Street, Annanagar, Chennai, Tamilnadu, India. Pin 600040 The future of the CNC machine tool processing industry is bright.As we delve into 2024 and beyond, the landscape of CNC machining is evolving rapidly, driven by technological advancements and industry demands. . One key trend is real-time data monitoring, where IoT-enabled CNC machines collect data on parameters like temperature and vibration . With all new technologies, adoption is slower than the industry pundits would have you believe. This is certainly true with one of Industry 4.0’s enabling technologies – the Internet of Things (IoT). In the manufacturing world, IoT also known as the Industrial Internet of Things (IIoT). These new technologies promise to shift the paradigm in the industry.Advantech’s industrial IoT solutions of CNC machine tools provide diverse data acquisition modules and industrial-grade panel computers for equipment suppliers to maximize production management, cutting tool management, intelligent monitoring, and other kinds of applications besides facilitating CNC machine tools to be the networking .

metal fabricator near me xfabrications

An automated tool changer can hold a variety of tool options, enabling a single CNC machine to perform multiple tasks successively without sacrificing speed or accuracy. The Role of the Internet of Things (IoT) in CNC Machine Monitoring . Incorporating IoT CNC machine monitoring systems has not only enhanced the productivity of manufacturing . Aerospace: Aerospace giants use IoT for CNC machining in the aerospace industry to produce more reliable and precise components, pushing the boundaries of aviation technology. Core components of IoT in CNC machines? Key components of IoT in CNC include: Sensors and actuators: Collect data and act upon it to adjust operations in real-time. By simulating tool paths and machine operations, manufacturers can identify potential issues and optimize processes. Virtual Machining: . Automation and the Internet of Things (IoT) are transforming CNC machining by enabling more efficient and connected operations. These technologies facilitate seamless communication between machines, tools .

B. Internet of Things for CNC Machine Monitoring. In the process of machining workpiece, the simulation . . monitoring parameter in CNC m achine is machine tool . temperature.84663020 Parts and accessories suitable for use solely or principally with the machines of headings 8456 to 8465, including work or tool holders, self-opening dieheads, dividing heads and other special attachments for machine-tools; tool holders for any type of tool, for working in the hand - dividing heads and other special attachments for .

Tool condition monitoring (TCM) systems have evolved into an essential requirement for contemporary manufacturing sectors of Industry 4.0. These systems employ sensors and diverse monitoring techniques to swiftly identify and diagnose tool wear, defects, and malfunctions of computer numerical control (CNC) machines. Their pivotal role lies in . 4. How does IoT enhance the performance of CNC spline grinding machines? The Internet of Things (IoT) enhances CNC spline grinding by enabling real-time monitoring and data analysis. IoT sensors collect data on machine performance, operational temperatures, and tool wear, providing insights for immediate adjustments.

iot integration in manufacturing

iot in cnc machinery

iot impact on cnc

The SL807 from ESR is a Standard 35mm Single Gang Surface Patress Box ideal for mounting any switches or sockets with a 35mm or lower minimum recessed depth. This box is constructed from high quality, durable scratch resistant thermoplastic, and features a simple and reliable design with round edges.

cnc machine tooling iot|integration of iot and cnc