how to become a sheet metal fabrication How to Become a Sheet Metal Fabricator. The qualifications to become a sheet metal fabricator include a high school diploma, relevant training or experience, and communication and math skills. There are a few different paths to begin this career. Used machining centers for sale in United Arab Emirates. Fanuc, Dufour, Fexac, and OKK. Find horizontal and vertical machining centers on Machinio.

0 · sheet metal worker skills

1 · sheet metal worker jobs

2 · sheet metal training near me

3 · sheet metal training courses

4 · sheet metal mechanical skills

5 · sheet metal jobs salary

6 · sheet metal apprenticeships

7 · precision sheet metal workers

$34.99

How to Become a Sheet Metal Fabricator. The qualifications to become a sheet metal fabricator include a high school diploma, relevant training or experience, and communication and math skills. There are a few different paths to begin this career.Becoming a sheet metal worker typically involves completing a combination of education and hands-on training, as well as obtaining industry certification. .

You are starting or running your business because you love doing metal fabrication. Seriously, if you don’t love the work, you probably need to find a new industry. Let’s say, however, that you inherited the family business and you .Qualifications to become a sheet metal foreman include a high school diploma or equivalent and an active Journeyman’s license, or verification that certification is in progress. You must have supervisory or foreman experience and the ability to read blueprints. Some employers require you to have an OSHA 30 certification.

Thinking of becoming a Fabricator? Learn more about the role including reviews from current Fabricators tasks and duties, how much Fabricators earn in your state, the skills employers are looking for and career pathways. . Stainless . Welding is an important aspect of metal fabrication, but welders usually focus solely on this aspect. Find welder jobs 2. Sheet metal worker National average salary: ,133 per year Primary duties: Sheet metal workers specialize in installing or repairing products made from thin metal sheets, such as ducts used in ventilation systems. They .Did you take the job? Sheet metal has such a wide variety of things to do. Stainless specialty, working in a shop, installation in the field or designing the systems yourself. It's actually a dream of mine when I'm done my apprenticeship (1.5 years left) to do sheet metal in Ireland for a year.The qualifications that you need to work as a sheet metal journeyman include experience and job skills. Most sheet metal journeymen start their careers with a high school diploma. Some vocational schools offer post-secondary certificates in sheet metal fabrication or duct installation. Employers may provide on-the-job training or apprenticeships.

A few usual roles for metal fabricators include: Creating sheet metal, jigs, fixtures, tools, molds, dies, gauges, patterns, and other essential parts to the production process; . Recommended Skills For Fabricators. Learning how to become a metal fabricator can be both rewarding and lucrative. However, it is crucial to understand that this .

This includes the basics of sheet metal fabrication, and it also includes inventory options and the basics of securing a reliable delivery schedule, through kanban replenishment programs and the like. . If you become Company A, your competition eventually will catch on and try to copy your success. The first movers have two to three years .

Metal fabrication, transforming raw metal into finished products, has evolved remarkably. What once relied heavily on manual labour and traditional techniques such as metal flattening, bending, and forming has been revolutionised by mechanical automation in modern metal fabrication workshops. Wrightform take a quick look into the journey of metal fabrication, . What level of education is required for Sheet Metal Fabricators? 51% of Sheet Metal Fabricators have a high school diploma degree, 15% major in precision metal working. Learn all about Sheet Metal Fabricator educational requirements, degrees, majors, certifications, online courses, and top colleges that will help you advance in a Sheet Metal Fabricator career. Elevating yor metal fabrication skills? Starting a sheet metal fabrication business might be just what you need. Learn more about it here. The Kickass Entrepreneur About; Blog. Create Wealth (Investing) . How to Become a Decamillionaire, Grow your Net Worth to Million, and Join the 1% Club. 32 Most Profitable Small Businesses To Open in .need help manufacturing sheet metal? want to post your fabrication for all to updoot? come to r/sheetmetal to discuss all things sheet metal. Design, Fabrication, Installation. Welding, HVAC, Roofing, commercial kitchen stainless, home renovation, sheet metal art & etc. ! . However once you become a journeyman you’ll be making some decent .

As with many specific trades, metal fabrication takes time; and to learn the methods of working with metal, adequate training through colleges and apprenticeships are necessary. If you are looking for a career in metal fabrication, it is necessary to learn the proper techniques to prepare properly for a job in the metal fabrication field. Sheet metal fabrication is the process of transforming metal sheets into various shapes through cutting, bending, and assembling. . However, the strain cannot exceed the metal’s ultimate tensile strength, or it will become . It takes 2-6 years to become a sheet metal engineer: Years 1-4: Obtaining a high school diploma and completing on-the-job training in sheet metal fabrication, installation, and repair. Years 5-6: Accumulating work experience in sheet metal cutting, shaping, and assembly. How does one define a true sheet metal professional, and what does it take to become one in the metal manufacturing sectors? Press brake guru Steve Benson provides insight and why it's important for metalworkers to .

In the metal fabrication business, everyone would rather be busy than slow, but that doesn’t mean it’s easy. In 2018 Amerequip Corp., a fabricator of custom equipment for the lawn, landscape, agricultural, and construction markets, was trying to keep up with a manufacturing economy that was red-hot.It had just completed a major expansion of its welding and . Fabrication sheet metal workers: They are also called precision sheet metal workers and they are the ones who actually make the metal sheets, in different shapes and sizes depending on their destination. Some metal sheet factories are completely computerized and the metal sheet workers operating there need to learn how to program the software . Becoming a skilled sheet metal worker involves mastering the fabrication, installation, and maintenance of metal components used in various industries like HVAC and construction. The path typically includes a high school education, a 4-5 year apprenticeship, and ongoing training.

Welding is an important aspect of metal fabrication, but welders usually focus solely on this aspect. Find welder jobs 2. Sheet metal worker National average salary: ,133 per year Primary duties: Sheet metal workers specialize in installing or repairing products made from thin metal sheets, such as ducts used in ventilation systems. They . Fabrication sheet metal workers, sometimes called precision sheet metal workers, make precision sheet metal parts for a variety of industries, including power generation and medical device manufacturing. They often work in shops and factories, operating tools and equipment. . Those interested in becoming a sheet metal worker should take high . Sheet metal mechanic National average salary: ,959 per year Primary duties: A sheet metal mechanic is responsible for cutting, shaping and installing sheet metal equipment, particularly for roofing, drainage pipes, air conditioning systems and ventilation ducts. They review the blueprints of an area and shape the sheet metal to fit into the .

It typically takes 2-6 years to become a sheet metal technician: Year 1: Beginning an apprenticeship or on-the-job training in sheet metal fabrication and installation. Years 2-4: Learning skills such as reading blueprints, cutting and forming sheet metal, and installing metal sheets or panels. The metal fabrication industry is currently on a transformative journey, navigating through rapid advancements and shifting trends. This is a result of continuous technological advancements, industry 4.0 and smart manufacturing, globalisation, customer demands for customisation and competitive pressures and innovations. In this blog, we explore the latest .

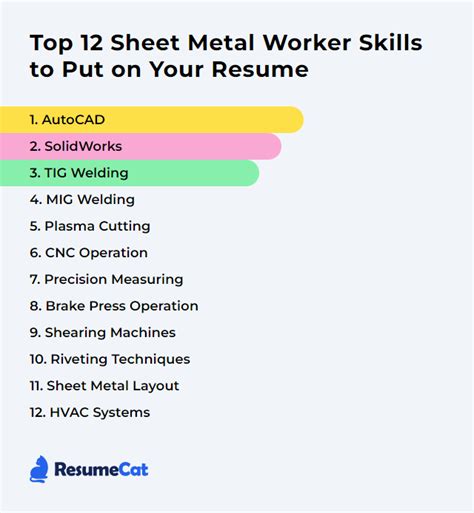

sheet metal worker skills

sheet metal worker jobs

Metal fabrication is the process of creating structures and machinery from raw metal materials. Metal fabricators, or the employees who perform this job, are highly important to the industry and need special skills to complete their tasks. . Qualifications to become a metal fabricator . Sheet metal works are responsible for creating and .

Dynamic, rewarding, and technologically advanced Metal Fabrication is a dynamic and rewarding career. You will enjoy working with steel, aluminum and other exotic metals. Work in a technologically advanced, diverse and team-based shop environment. You will learn to develop concepts and ideas into the fabricated legacies of the future. You will earn an above average

sheet metal training near me

sheet metal training courses

sheet metal mechanical skills

$59K+

how to become a sheet metal fabrication|sheet metal jobs salary