catia v5 generative sheet metal design This course will teach you how to design a sheet metal part using associative feature-based modeling. Standard and user-defined stamped features can be integrated into the design and .

The Battery Junction Box is used to monitor and shut down the battery. ☛ With end-of-line test systems we bring safety into the electric vehicle.

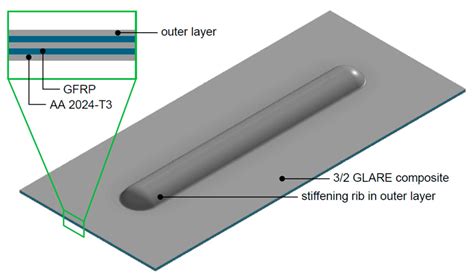

0 · sheet metal stiffening rib design

1 · sheet metal design practice pdf

2 · CATIA sheet metal exercises pdf

3 · CATIA sheet metal design pdf

4 · CATIA part modeling pdf

5 · CATIA gsd exercises pdf

6 · CATIA design diagram

7 · CATIA bend from flat

Metallic dyes get their name from the use of metallic salts that create the unique coloring. These dyes are used in progressive color treatment programs and can cover gray, as well as add an exotic look to your hair. The more you apply it, .

sheet metal stiffening rib design

Natively integrated, SheetMetal Design offers the same ease of use and user interface consistency as all V5 applications. As a scalable product, SheetMetal Design can be used in . In this video we create a simple model with Generative Sheet Metal Design in CATIA V5.The Generative Sheetmetal Design workbench is a new generation product .

Step 1: Generative SheetMetal Design. Gussets are triangular or L-shaped reinforcements that are typically added to sheet metal components to improve their strength .

what is a phone junction box

There are a few workbenches in CATIA V5 that deal with sheet metal options. Many of the options appear in more than one sheet metal workbench. They will only be covered once. This course .Learn how to create sheet metal features like holes, cutouts and stamps. You will also learn to apply dress-up features like fillets and chamfers. Learn how to create multiple instances of a feature using patterns and powercopies. You will also .This course will teach you how to design a sheet metal part using associative feature-based modeling. Standard and user-defined stamped features can be integrated into the design and .You are provided with a process-based approach to creating sheet metal models. Each step in the process is discussed in depth using lectures and several hands-on practices. This training .

This four step tutorial shows how to model sheet metal part in Catia generative sheetmetal design workbench. This Tutorial Contains CATIA v5 Sheetmetal design videos for getting started with sheetmetal design

The Generative Sheetmetal Design User's Guide has been designed to show you how to design sheet metal parts of varying levels of complexity. Before reading this guide, you should be familiar with basic Version 5 concepts such as documentNatively integrated, SheetMetal Design offers the same ease of use and user interface consistency as all V5 applications. As a scalable product, SheetMetal Design can be used in cooperation with other current or future companion products in CATIA V5 such as Assembly Design and Generative Drafting.

In this video we create a simple model with Generative Sheet Metal Design in CATIA V5.The Generative Sheetmetal Design workbench is a new generation product . Step 1: Generative SheetMetal Design. Gussets are triangular or L-shaped reinforcements that are typically added to sheet metal components to improve their strength and stiffness. In CATIA V5 Generative SheetMetal design, gussets can be created using a variety of methods, including:There are a few workbenches in CATIA V5 that deal with sheet metal options. Many of the options appear in more than one sheet metal workbench. They will only be covered once. This course will discuss all of the options found in the Generative Sheetmetal Design and Aerospace Sheet Metal Design workbenches.Learn how to create sheet metal features like holes, cutouts and stamps. You will also learn to apply dress-up features like fillets and chamfers. Learn how to create multiple instances of a feature using patterns and powercopies. You will also learn to move, rotate or scale features.

This course will teach you how to design a sheet metal part using associative feature-based modeling. Standard and user-defined stamped features can be integrated into the design and the resulting flat pattern is calculated in accordance with standard bend allowances or with company specific bend allowance tables.You are provided with a process-based approach to creating sheet metal models. Each step in the process is discussed in depth using lectures and several hands-on practices. This training course focuses on the Generative Sheet Metal Design workbench. Topics Covered in this CATIA V5 Training Course:

This four step tutorial shows how to model sheet metal part in Catia generative sheetmetal design workbench.

This Tutorial Contains CATIA v5 Sheetmetal design videos for getting started with sheetmetal design

The Generative Sheetmetal Design User's Guide has been designed to show you how to design sheet metal parts of varying levels of complexity. Before reading this guide, you should be familiar with basic Version 5 concepts such as documentNatively integrated, SheetMetal Design offers the same ease of use and user interface consistency as all V5 applications. As a scalable product, SheetMetal Design can be used in cooperation with other current or future companion products in CATIA V5 such as Assembly Design and Generative Drafting.In this video we create a simple model with Generative Sheet Metal Design in CATIA V5.The Generative Sheetmetal Design workbench is a new generation product . Step 1: Generative SheetMetal Design. Gussets are triangular or L-shaped reinforcements that are typically added to sheet metal components to improve their strength and stiffness. In CATIA V5 Generative SheetMetal design, gussets can be created using a variety of methods, including:

There are a few workbenches in CATIA V5 that deal with sheet metal options. Many of the options appear in more than one sheet metal workbench. They will only be covered once. This course will discuss all of the options found in the Generative Sheetmetal Design and Aerospace Sheet Metal Design workbenches.Learn how to create sheet metal features like holes, cutouts and stamps. You will also learn to apply dress-up features like fillets and chamfers. Learn how to create multiple instances of a feature using patterns and powercopies. You will also learn to move, rotate or scale features.This course will teach you how to design a sheet metal part using associative feature-based modeling. Standard and user-defined stamped features can be integrated into the design and the resulting flat pattern is calculated in accordance with standard bend allowances or with company specific bend allowance tables.

You are provided with a process-based approach to creating sheet metal models. Each step in the process is discussed in depth using lectures and several hands-on practices. This training course focuses on the Generative Sheet Metal Design workbench. Topics Covered in this CATIA V5 Training Course: This four step tutorial shows how to model sheet metal part in Catia generative sheetmetal design workbench.

what is a.metal roof on house trailer made of

One of the most difficult aspects of reporting IRA and retirement plan distributions is determining the proper distribution code(s) to enter in Box 7 on IRS Form 1099-R. We’ve called out each distribution code that may apply and explained when to use each.

catia v5 generative sheet metal design|CATIA sheet metal design pdf