electrical clearance in front of a j box On side note the Jbox will not be blocked by the desk entirely, the Jbox will be installed at approx. 5 ft, a couple feet above the desk top, so they can be accessed. The question was do we need the 3 ft open clearance in front of the Jbox, like we do for a distribution panel? Computer Numerical Control (CNC) Machining is the process through which computers control machine-based processes in manufacturing. The kinds of machines controlled include lathes, mills, routers and grinders – .

0 · nec junction box clearance

1 · junction box relay clearance

2 · junction box nec size

3 · junction box clearance requirements

4 · electrical junction box nec

5 · electrical junction box code

6 · electrical front clearance requirements

7 · clearance for electrical work space

If your project needs electrical boxes or enclosures, and you don’t know what are the main types of electrical enclosures, you need to read this guide, I will tell you 76 types of electrical boxes for your business based on .

On side note the Jbox will not be blocked by the desk entirely, the Jbox will be installed at approx. 5 ft, a couple feet above the desk top, so they can be accessed. The question was do we need the 3 ft open clearance in front of the Jbox, like we do for a distribution panel?What rule in the code governs how much clearance you need in front of and/or .Most consider a typical junction box not needing to be worked on while .

What rule in the code governs how much clearance you need in front of and/or around a standard junction box? Or for that matter any sized pull or junction box?

Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be . Most consider a typical junction box not needing to be worked on while energized, so it wouldn't need working space. However it would need to be accessible. No magic .Working space is the component of the “clearance” that is directly in front of the accessible sides of electrical equipment. All electrical equipment requires some degree of working space to .

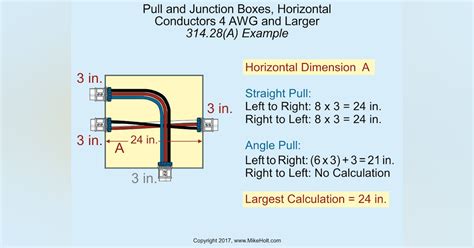

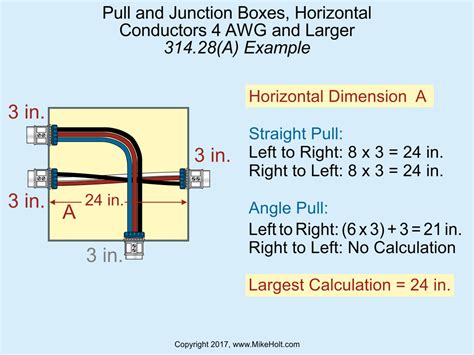

Installations built before the 1978 NEC only require a minimum clearance of 2 ft in front of electrical equipment. The 30-in.-wide rule has been used since the 1971 NEC. Headroom clearance has been required since the . Working space is not required at the back or sides of equipment where all connections and all renewable, adjustable, or serviceable parts are accessible from the front (dead-front equipment) [Sec. 110.26(A)(1)(a)]. The rules for pull boxes, junction boxes, and outlet boxes cover five areas. In summary: Minimum size [314.28(A)]. These requirements constitute most of Sec. 314.28. One key point is that on straight pulls the box or conduit . On side note the Jbox will not be blocked by the desk entirely, the Jbox will be installed at approx. 5 ft, a couple feet above the desk top, so they can be accessed. The question was do we need the 3 ft open clearance in front of the Jbox, like we do for a distribution panel?

You must provide a minimum working space with 3 feet of clearance in front of and around electrical equipment for safe operation and maintenance. The working space must be clear and unobstructed and extend from the floor to the required height.

nec junction box clearance

What rule in the code governs how much clearance you need in front of and/or around a standard junction box? Or for that matter any sized pull or junction box?Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be able to open a minimum of 90 degrees.

35mm metal curtain pole brackets

Most consider a typical junction box not needing to be worked on while energized, so it wouldn't need working space. However it would need to be accessible. No magic distance, just accessible by the smallest fingers. Here is an article to discuss it.Working space is the component of the “clearance” that is directly in front of the accessible sides of electrical equipment. All electrical equipment requires some degree of working space to allow access and safe operation and maintenance of the equipment. Installations built before the 1978 NEC only require a minimum clearance of 2 ft in front of electrical equipment. The 30-in.-wide rule has been used since the 1971 NEC. Headroom clearance has been required since the 1965 NEC.

Working space is not required at the back or sides of equipment where all connections and all renewable, adjustable, or serviceable parts are accessible from the front (dead-front equipment) [Sec. 110.26(A)(1)(a)]. The rules for pull boxes, junction boxes, and outlet boxes cover five areas. In summary: Minimum size [314.28(A)]. These requirements constitute most of Sec. 314.28. One key point is that on straight pulls the box or conduit body length must be at least eight times the trade size of the raceway. The specific electrical panel clearance requirements will depend on what area you are looking at, and how much voltage there is going through the panel. Most people think only about the area directly in front of the electrical panel.

junction box relay clearance

On side note the Jbox will not be blocked by the desk entirely, the Jbox will be installed at approx. 5 ft, a couple feet above the desk top, so they can be accessed. The question was do we need the 3 ft open clearance in front of the Jbox, like we do for a distribution panel? You must provide a minimum working space with 3 feet of clearance in front of and around electrical equipment for safe operation and maintenance. The working space must be clear and unobstructed and extend from the floor to the required height.

What rule in the code governs how much clearance you need in front of and/or around a standard junction box? Or for that matter any sized pull or junction box?Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be able to open a minimum of 90 degrees.

Most consider a typical junction box not needing to be worked on while energized, so it wouldn't need working space. However it would need to be accessible. No magic distance, just accessible by the smallest fingers. Here is an article to discuss it.

Working space is the component of the “clearance” that is directly in front of the accessible sides of electrical equipment. All electrical equipment requires some degree of working space to allow access and safe operation and maintenance of the equipment. Installations built before the 1978 NEC only require a minimum clearance of 2 ft in front of electrical equipment. The 30-in.-wide rule has been used since the 1971 NEC. Headroom clearance has been required since the 1965 NEC.

Working space is not required at the back or sides of equipment where all connections and all renewable, adjustable, or serviceable parts are accessible from the front (dead-front equipment) [Sec. 110.26(A)(1)(a)]. The rules for pull boxes, junction boxes, and outlet boxes cover five areas. In summary: Minimum size [314.28(A)]. These requirements constitute most of Sec. 314.28. One key point is that on straight pulls the box or conduit body length must be at least eight times the trade size of the raceway.

junction box nec size

36 electric builders box

357 best kutular imagens metal die cut box

In this extensive guide, we have covered the fundamentals of CNC turning inserts, explored the different types, materials, and coatings available, and provided valuable tips for selecting and using the right insert for optimal efficiency.

electrical clearance in front of a j box|junction box clearance requirements