copper backing for welding sheet metal Trying to weld thin sheet metal together, but constantly blowing through the metal? rThe easy solution is a copper weld backer. Weld will not stick to these weld backers which support the . Cerbonny Kids Lunch Box, Yellow-3, Unisex, Polyester, With Insulation, Easy-clean, Multiple Carrying Options, Big Capacity, Lightweight, Quality Guaranteed

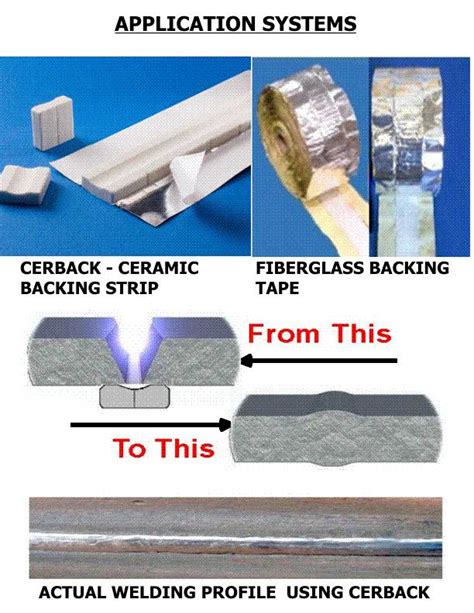

0 · welding with ceramic backing strip

1 · types of welding backing strip

2 · permanent backing strip weld

3 · magnetic copper welding backer

4 · copper welding backer harbor freight

5 · cjp weld with backing bar

6 · backing bar weld symbol

7 · backing bar thickness chart

Reviews on Metal Fabricators in Penn Yan, NY 14527 - Milo Manufacturing, Westerfield Fabrication, CM Fabrication, Keuka Studios, Rogers Welding & Machine

As mentioned the copper is just a temporary backing to help fill the holes in, it also acts like a heat sink and copper doesn't stick as easy to your work like a steel backing would. I used a copper chill bar this past weekend with great success. The reason copper won't weld is simply thermal conductivity. It's difficult to localize the heat enough to melt the substrate. That said, if you try to plug-weld a quarter-sized 1/4" hole and you back it with a small thin copper .

welding sheet metal using a copper backing plate to make better welds with out blowing holes. From http://www.kevincaron.com - Artist Kevin Caron shares a tip on how to patch a hole in steel by backing it with a piece of copper before welding.Trying to weld thin sheet metal together, but constantly blowing through the metal? rThe easy solution is a copper weld backer. Weld will not stick to these weld backers which support the . To help dissipate heat faster you can clamp a backing bar to the work metal. This metal backing bar will usually be made from copper or aluminum and will draw heat out of the work metal to help prevent warping or burn through.

Backing bars are placed under the weld joint and as copper do not fuse with carbon steel, copper backing bar are very famous in welding applications. Use restrains and clamps Using clamps or restrains during thin .

Can copper help you MIG weld holes in sheet metal? Lets make a copper backing plate and find out.(Affiliate links to help support channel) 🙏👉Eastwood MP140.Magnetic copper backing panel provides hands-free support when doing butt-welding or welding holes in sheet metal. 4" long Magnetic Copper Backer helps you weld without burning holes.

As mentioned the copper is just a temporary backing to help fill the holes in, it also acts like a heat sink and copper doesn't stick as easy to your work like a steel backing would. I used a copper chill bar this past weekend with great success.

The reason copper won't weld is simply thermal conductivity. It's difficult to localize the heat enough to melt the substrate. That said, if you try to plug-weld a quarter-sized 1/4" hole and you back it with a small thin copper sheet, you will weld it to the steel.

welding sheet metal using a copper backing plate to make better welds with out blowing holes. Copper backing bars are used in welding to provide a heat-conducting and electrical-conducting path between the weld and the workpiece. This helps to prevent weld defects and improve weld quality. Copper backing bars can be used for both gas tungsten arc welding (GTAW) and plasma arc welding (PAW).

From http://www.kevincaron.com - Artist Kevin Caron shares a tip on how to patch a hole in steel by backing it with a piece of copper before welding.Trying to weld thin sheet metal together, but constantly blowing through the metal? rThe easy solution is a copper weld backer. Weld will not stick to these weld backers which support the weld from blowing though and also absorb some heat, to help reduce warping.

To help dissipate heat faster you can clamp a backing bar to the work metal. This metal backing bar will usually be made from copper or aluminum and will draw heat out of the work metal to help prevent warping or burn through. Backing bars are placed under the weld joint and as copper do not fuse with carbon steel, copper backing bar are very famous in welding applications. Use restrains and clamps Using clamps or restrains during thin sheet welding help to prevent distortion.

Can copper help you MIG weld holes in sheet metal? Lets make a copper backing plate and find out.(Affiliate links to help support channel) 🙏👉Eastwood MP140.Magnetic copper backing panel provides hands-free support when doing butt-welding or welding holes in sheet metal. 4" long Magnetic Copper Backer helps you weld without burning holes. As mentioned the copper is just a temporary backing to help fill the holes in, it also acts like a heat sink and copper doesn't stick as easy to your work like a steel backing would. I used a copper chill bar this past weekend with great success.

The reason copper won't weld is simply thermal conductivity. It's difficult to localize the heat enough to melt the substrate. That said, if you try to plug-weld a quarter-sized 1/4" hole and you back it with a small thin copper sheet, you will weld it to the steel.

welding sheet metal using a copper backing plate to make better welds with out blowing holes. Copper backing bars are used in welding to provide a heat-conducting and electrical-conducting path between the weld and the workpiece. This helps to prevent weld defects and improve weld quality. Copper backing bars can be used for both gas tungsten arc welding (GTAW) and plasma arc welding (PAW).

From http://www.kevincaron.com - Artist Kevin Caron shares a tip on how to patch a hole in steel by backing it with a piece of copper before welding.Trying to weld thin sheet metal together, but constantly blowing through the metal? rThe easy solution is a copper weld backer. Weld will not stick to these weld backers which support the weld from blowing though and also absorb some heat, to help reduce warping.

To help dissipate heat faster you can clamp a backing bar to the work metal. This metal backing bar will usually be made from copper or aluminum and will draw heat out of the work metal to help prevent warping or burn through. Backing bars are placed under the weld joint and as copper do not fuse with carbon steel, copper backing bar are very famous in welding applications. Use restrains and clamps Using clamps or restrains during thin sheet welding help to prevent distortion. Can copper help you MIG weld holes in sheet metal? Lets make a copper backing plate and find out.(Affiliate links to help support channel) 🙏👉Eastwood MP140.

welding with ceramic backing strip

types of welding backing strip

$12.64

copper backing for welding sheet metal|copper welding backer harbor freight