fill in junction box hole What is the NEC compliant method for plugging an unused knockout hole where a conduit connector used to be? I see different types - the pop in friction fit, and the mechanical fastener fit with a screw or wing nut. $42.99

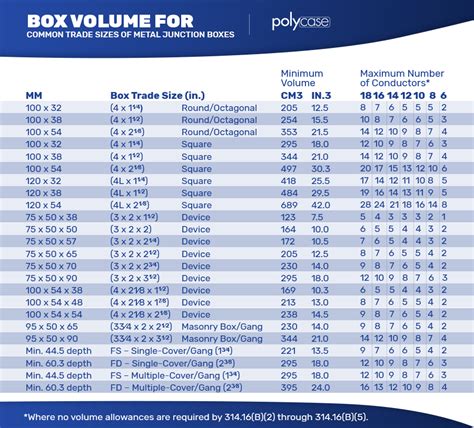

0 · junction box size chart

1 · junction box size calculator

2 · junction box holes in drywall

3 · junction box holes ceiling

4 · how to calculate box fill

5 · fixture box fill calculator

6 · fixing junction box holes

7 · electrical box fill calculator

What I'm saying is that if you had two 12/2 cable and two 14/2 cables there is no reason that all four EGC need to be spliced together. If the box is metallic the largest EGC .

In this video i demonstrate how to fill holes in the ceiling that have been exposed because light fixtures have been re positioned, also you'll learn how to put all those old stir sticks you've.

A "knockout fill plug" - costs a few cents (depending on supplier - some are over a buck, I'd keep shopping), snaps into the hole (take the clamp out first.) Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®. What is the NEC compliant method for plugging an unused knockout hole where a conduit connector used to be? I see different types - the pop in friction fit, and the mechanical fastener fit with a screw or wing nut. Unused cable or raceway openings in boxes, raceways, auxiliary gutters, cabinets, cutout boxes, meter socket enclosures, equipment cases, or housings shall be effectively .

Correct fill capacity: The junction box should be large enough to contain the wires. Many DIYers choose the largest box practical for the application. To stay within code-approved limits, though, consult a fill capacity .

One of the screw holes on a junction box on my ceiling has fallen apart, leaving a hole that is too big to fix a screw into (see top of picture). As a result, I cannot hang my smoke detector from the junction box, since the . An oversized drywall cutout around an electrical box can ruin the appearance of an otherwise perfect taping job. The best way to fix it is with drywall compound and joint tape.

metal gates fabrication utah

junction box size chart

Learn how to repair holes around electrical box video! With these contractor tips and DIY tricks! In this video, I demonstrate how a large hole is filled in a wall. In this case, I am filling in an old electrical box that is no longer needed and I am feel. Making holes in junction boxes. . 6x6 junction boxes don't come with 2" or 1-1/2" knockouts, so I need to make my own holes. . I'm planning to use 1-1/2" EMT which is larger than the 1-1/4" minimum for the conduit fill requirement. If there's something else I should be aware of, a code citation would be handy for convincing me. It was designed to clamp onto 1/2" drywall, but for patching puroses you need it open to 5/8" or 3/4" or even 1" thick wall material. Depending on the clamp opening, you should attach a backer of 1/4" or 3/8" plywood to .

Commercial Electric weatherproof boxes are designed for use in branch circuit wiring in wet, damp or dry locations. Boxes house receptacles, switches and GFCI's. Boxes may also be used as a weatherproof junction box. Closure . The original outlet was an outdoor outlet in the stucco so with the extra inches the junction box barely reaches the outside drywall. . to the stud and then use an extesion from the box to hopefully fill in the gap to the drywall. – Pinky_M. Commented Apr 6, 2022 at 20:50. Add a comment | 2 With a saw cut a tidy hole for a 2-gang box but 3/ .

Industrial control-panel enclosures shall not be used as junction boxes, auxiliary gutters, or raceways for conductors feeding through or tapping off to other switches or overcurrent devices or other equipment, unless the conductors fill less than 50% of the cross-sectional area of the wiring space. a. True b. False Given that the box is plastic, you have at least 3 options: Try a slightly larger screw. Fill the mounting hole(s) in the box with epoxy, drill a new hole, and re-mount the outlet. Replace the box. If it were me, I would do number 3. Obviously, make sure the electricity to the outlet is turned off before doing any work. Edit 1 : OP says the box .

110.3 says it needs to be listed for the application, and much the same as other junction boxes, there's not much in the way of excluding making your own holes 314 says in order to use it as a junction box that contains splices the body has to be stamped with the amount of cubic area, but that doesn't exclude making holes in the side and adding .Patch the old hole with a self-sticking drywall patch, then mount a new box to the joist about 8" further away from the wall. There are boxes that can be screwed right into the joist from below the ceiling (look for Madison Electric Products Fan and Fixture 1-Gang Gray Polycarbonate New Work/Old Work Standard Ceiling Fan Ceiling Electrical Box).

comments r/HomeImprovement These holes are built-in to the junction box which is made of plastic or some brownish and brittle material. I suspect this was caused by someone trying to overcome a too-crowded (or poorly laid out) junction box by using these screws to force the receptacle into the box. What is the solution without replacing the junction box? In a ceiling that becomes a big problem for a box that is "just a box" because most people don't like blank/filler plates in the ceiling. (Exception: with a drop-ceiling there is no accessibility issue - just remove a tile.) So a junction box that is by design integral to the light fixture works but a nearly identical box 6" away does not.

If me, I'd clean it all out as much as possible and fill the screw holes and surrounding areas with 2-part epoxy. Then drill new holes. You can buy switch & outlet spacers at the big box in the electrical section (there's even a picture of this exact scenario). These are stackable spacers that go behind the tabs and the mounting screw goes . So long as there is access to that 'new' line/junction box (in the attic). Then all you have is an old hole/box that you need to cover.. Then you can try and remove the old box (possibly)..and block the old hole from behind and install some drywall, - tape, mud and finesse (!!) the area to suitable match to the original wall finish. It is designed to fill a hole 0.875 inches in diameter. Plugs with a trade size of ⅜ of an inch come closest, but they are a bit too small, filling holes 0.718 inches in diameter. Just about every time I go troubleshoot some kind of fountain pump or light, I open up the brass Hadco junction box and find it filled to the brim with silicone caulk. I used to think it was because some maintenance guy or handy man tried to change out the pump and ripped up the gasket taking the cover off, but recently I've come across some .

Take a piece of wood and make a hole in it with the hole saw for 1 1/4 pipe. Clamp it over the hole you need to make larger the wood will support the hole saw so it doesn't slide around. Another option is to try and use an 1 1/8 hole saw as the arbor for the hole saw for 1 1/4. Edit: sorry if that doesn't make sense. After slicing 90 deg the box would be rotated 90 deg to continue the cut . . . Alternatively, the box could be held down on a flat surface and the knife held with the cutting edge away from the thumb. The removal would be . Be sure to fill in the gaps between the round box and the sheating/housewrap with a sealant, I like to use duct seal putty. . and then cut my junction box hole all the way through both pieces of plywood into the house? That would effectively make up a majority of the gap between the junction box and the light base. Top. Shannon Posts: 21872 .

First, determine the size of the missing knockout hole and subtract 3/8" to figure out what size knockout plug you'll need. For example, if you have a 7/8" hole, you'll need a 1/2" knockout plug .Ive yet to see a ground level jbox in my career that doesnt get water in it. Id be surprised if that romex (the orange cable, 100% not allowed to be used outside, let alone be buried) was deeper than a couple inches. Exception: Where nonmetallic-sheathed cable or multiconductor Type UF cable is used with single gang boxes not larger than a nominal size 57 mm x 100 mm (2-1/4 in. x 4 in.) mounted in walls or ceilings, and where the cable is fastened within 200 mm (8 in.) of the box measured along the sheath and where the sheath extends through a cable .

how would a 6" box help solve that? It would fill the drywall hole. So the separation between interior space and attic would be either drywall, or junction box, which is pretty normal. No part where nothing divides it. I get I could fill the gap with something, but filling it with junction box seemed the easiest.Looks like there's a stud along the right side of the box, between this gang box and the switch or whatever is to the right. Remove the outlets, then while holding the box in place, drive wood screws at as shallow of an angle as you can through the box and into the stud. You may want to pre-drill holes through the box first.You reach the maximum number of conductors in the box well before you run out of knock out space. I double up sometimes for 3 cable boxes because it's easier to lay the wires neatly in the box if they are all going the same direction. The shallowest Carlon nonmetallic boxes (at 1.25" deep), while technically deep enough for a receptacle (at only 0.69" for the receptacle + the minimum 1/4" of extra depth required by Code), do not provide enough box fill at 8in3 to accommodate a hot, a neutral, a ground, an allowance for a cable clamp, and the double allowance for the .

metal gear cardboard box cosplay

Just answer the questions below and we will do the box fill calculations for you based on Article 314.16 of the National Electrical Code. Smash Budgets with Daily Productivity Goals. Data Results; Number of Wires Terminating in the Box: Per NEC 314.16(B)(1) Enter each conductor that originates outside the box and terminates in the box. .

Beware the false economy. Using larger conduit gives you options in the future. Considering the total cost of the job, is the tiny percentage savings in cheaping out on the junction box sensible? Also, if possible, consider if you can put it where there's 270 degrees of bend on either side rather than 360 & 180. 360 is to code, but miserable to pull in practice, not unlike .

junction box size calculator

metal gear solid 1 box locations

junction box holes in drywall

I did see one massive Okuma bridge mill in the factory, but the vast majority of Doosan machines are made on other Doosan machines. My tour was conducted by Dongil .

fill in junction box hole|fixture box fill calculator