cnc machine maintenance book pdf By following this preventive maintenance guide, you can minimize unexpected breakdowns, optimize machine performance, and extend the lifespan of your CNC machine. Download our . The Light switch wiring diagram above shows electrical power entering the ceiling light electrical box and then continuing to a wall switch using a three-conductor cable. A 2-conductor cable was used from the wall switch to power two electrical receptacle outlets.

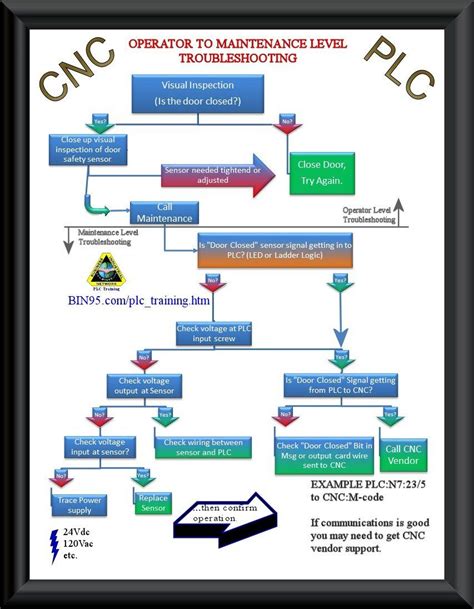

0 · TROUBLESHOOTING GUIDE FOR CNC MACHINES

1 · Quick Guide to CNC Machine Maintenance

2 · MILL WEEKLY MAINTENANCE CHECKLIST

3 · HAAS CNC MACHINE TOOL PREVENTIVE

4 · Fanuc Cnc Manual Machine Maintenance (book)

5 · Fanuc CNC Maintenance Manual PDF

6 · Comprehensive Guide to CNC Preventive Maintenance

7 · Complete CNC Machine Preventive Maintenance Checklist:

8 · CNC Daily Maintenance Checklist

9 · Appendix III

12 Pack Low Voltage Mounting Brackets 1 Gang for Drywall Outlet Cable Pass .

By following this preventive maintenance guide, you can minimize unexpected breakdowns, optimize machine performance, and extend the lifespan of your CNC machine. Download our .This document provides a list of tasks that are recommended to be completed on a daily and weekly basis to ensure the proper maintenance and performance of a Haas mill can be .defects, and premature wear on the machine. Record Keeping: Maintain a detailed log of all maintenance activities, including dates, procedures performed, and any findings. This is .Maintenance preformed to retain the machine in its original condition, to the extent possible, by providing systematic inspection, periodical checking servicing, detection and prevention of .

This document provides a daily preventive maintenance check list for CNC machines.

HAAS CNC MACHINE TOOL PREVENTIVE MAINTENANCE CHECKLIST © 2021 Haas Automation, Inc. | www.HaasCNC.com | 805-278-1800 MECHANICAL SYSTEM Verify .Appendix III- Machine Maintenance checklist - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. This document provides a checklist for performing preventative maintenance on a CNC machine.This document provides information about Fanuc CNC maintenance manuals. It lists several Fanuc manuals related to maintenance including manuals for servo amplifiers, CNC control .By following this preventive maintenance guide, you can minimize unexpected breakdowns, optimize machine performance, and extend the lifespan of your CNC machine. Download our PDF guide for easy reference, and keep your CNC machine running smoothly.

This document provides a list of tasks that are recommended to be completed on a daily and weekly basis to ensure the proper maintenance and performance of a Haas mill can be achieved. Run spindle warm-up program. We recommend you put a tool holder in the spindle while running.defects, and premature wear on the machine. Record Keeping: Maintain a detailed log of all maintenance activities, including dates, procedures performed, and any findings. This is crucial for tracking machine health and anticipating future needs. IV. Utilizing the Fanuc Manual: Your Fanuc CNC machine's manual is your most valuable resource.Maintenance preformed to retain the machine in its original condition, to the extent possible, by providing systematic inspection, periodical checking servicing, detection and prevention of failure likely to occur.This document provides a daily preventive maintenance check list for CNC machines.

cnc router machine for woodworking

HAAS CNC MACHINE TOOL PREVENTIVE MAINTENANCE CHECKLIST © 2021 Haas Automation, Inc. | www.HaasCNC.com | 805-278-1800 MECHANICAL SYSTEM Verify machine levelAppendix III- Machine Maintenance checklist - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. This document provides a checklist for performing preventative maintenance on a CNC machine.This document provides information about Fanuc CNC maintenance manuals. It lists several Fanuc manuals related to maintenance including manuals for servo amplifiers, CNC control units, spindle servo units, and IO units.

The CNC Operator software enables your PC or IPC to be used as the operator console of the CNC Controller. This manual describes how to operate CNC Operator when primarily using the CNC Controller.Lathe Maintenance and Safety Manual PRE 704-0214-201, B Machine Components 1-1 MACHINE COMPONENTS Overview Hurco machining centers use microprocessor-based computer numerical control (CNC) digital control systems. Part programs are entered in either Conversational or Conventional NC (G-Code) format.By following this preventive maintenance guide, you can minimize unexpected breakdowns, optimize machine performance, and extend the lifespan of your CNC machine. Download our PDF guide for easy reference, and keep your CNC machine running smoothly.

This document provides a list of tasks that are recommended to be completed on a daily and weekly basis to ensure the proper maintenance and performance of a Haas mill can be achieved. Run spindle warm-up program. We recommend you put a tool holder in the spindle while running.

defects, and premature wear on the machine. Record Keeping: Maintain a detailed log of all maintenance activities, including dates, procedures performed, and any findings. This is crucial for tracking machine health and anticipating future needs. IV. Utilizing the Fanuc Manual: Your Fanuc CNC machine's manual is your most valuable resource.Maintenance preformed to retain the machine in its original condition, to the extent possible, by providing systematic inspection, periodical checking servicing, detection and prevention of failure likely to occur.This document provides a daily preventive maintenance check list for CNC machines.HAAS CNC MACHINE TOOL PREVENTIVE MAINTENANCE CHECKLIST © 2021 Haas Automation, Inc. | www.HaasCNC.com | 805-278-1800 MECHANICAL SYSTEM Verify machine level

Appendix III- Machine Maintenance checklist - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. This document provides a checklist for performing preventative maintenance on a CNC machine.This document provides information about Fanuc CNC maintenance manuals. It lists several Fanuc manuals related to maintenance including manuals for servo amplifiers, CNC control units, spindle servo units, and IO units.The CNC Operator software enables your PC or IPC to be used as the operator console of the CNC Controller. This manual describes how to operate CNC Operator when primarily using the CNC Controller.

TROUBLESHOOTING GUIDE FOR CNC MACHINES

Quick Guide to CNC Machine Maintenance

cnc router machining aluminum

This 4 way switch diagram #1 shows the power source starting at the left 3-way switch. This 4 way switch diagram #2 shows the power source starting at the fixture. The white wire of the cable going to the switch is attached to the black line in the fixture box using a wirenut.

cnc machine maintenance book pdf|CNC Daily Maintenance Checklist