sheet metal processing The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material . $32.99

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal process in manufacturing

4 · sheet metal fabrication techniques

5 · sheet metal diagram fabrication

6 · disadvantages of sheet metal

7 · basic sheet metal fabrication techniques

At 8.07'' tall and roughly 5.7 inches in diameter, this decorative house sculpture is meant to house a real or LED candle in its base which when lit up gives off a very cool warm glow. Made of metal for longevity, this piece is sure to dazzle in any home setting.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material .Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes.Sheet metal processing is a method that manipulates flat sheets of metal into desired shapes and structures. Understanding the sheet metal forming process gives us insights into the world of manufacturing, revealing the ingenious .

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In .Sheet Metal Processing - un partener de încredere Venim în sprijinul afacerii dvs. cu mai mult de 10 de ani experiență în tehnologia de procesare a tablelor metalice, și ani de experiență în producție, a ajutat la decizia de a stabili .Microscopic close-up of mild steel sheet metal. Sheet metal is metal formed into thin, flat pieces, . It is commonly used in chemical processing equipment, light reflectors, and jewelry. [5] Grade 3003-H14 is stronger than 1100, while .

We are a Latvian metalworking, sheet metal processing and fabrication company. We offer metal laser cutting, bending and folding and fabricated part aftertreatment services. Our end product is sheet metal parts: blank pieces . Sheet metal processing commonly used materials are cold rolled sheet (SPCC), hot rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (CU), brass, red copper, beryllium copper, aluminum plate (6061, 6063, hard aluminum, etc.), stainless steel. What is sheet metal processing? Sheet metal processing are parts made by a comprehensive cold working process for thin metal plates (usually less than 6mm), including shearing, punching, cutting, bending, welding, riveting, splicing, forming, etc.

various sheet metal processes

Our Capabilities: Sheet Metal Fabrication, CNC Machining, Metal Stamping FZ Metalwork Co., Ltd. China Custom Metal Parts Manufacturer with more than 20 years experience. . Products produced through sheet metal processing, metal stamping, and CNC machining. Stamping Parts 2. 2022 08-29. CNC Parts 2. 2022 08-29. Stamping Parts 1. 2022 08-29 . 31 talking about this In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking Operations

Our team of skilled professionals, with years of experience in sheet metal fabrication, is dedicated to delivering top-quality results for your projects. 2. Advanced Technology. We employ cutting-edge equipment and techniques, ensuring your sheet metal components are produced with precision and efficiency. 3. Custom SolutionsCapps Manufacturing is an experienced sheet metal processing facility in Wichita, KS providing aircraft sheet metal part finishing & testing. Our aircraft sheet metal fabrication capabilities and equipment allow us to complete many components in-house from start to finish. Since 1983, we’ve served business, commercial and military aircraft companies all over the world.

sheet metal v notcher

Sheet metal processing in Switzerland: precision and efficiency to perfection. For years, our company has established itself as a pioneer in sheet metal processing and sheet metal fabrication in Switzerland. With the highest level of commitment and technological expertise, we realise sheet metal work that is second to none in terms of quality .Sheet Metal Processing Services Sheet metal processing includes traditional cutting, punching, bending and forming methods and process parameters, including a variety of cold stamping die structure and process parameters, a variety of equipment working principles and control methods, but also including stamping new technologies and new processes. Tolerance as tight as .CUTTING EDGE Materials Processing Corporation offers large format, high-precision sheet metal fabrication for the construction and industrial sectors of the Philippines.. Cutting Edge’s superior products are unparalleled in quality and innovation. They are created using an origami-like technique where a 2D thin sheet of metal is cut and formed into its desired shape and function .Dener Makina’s high technology metal sheet processing, metal cutting and shaping machines can be examined individually. Location Contact 1215 Bowes Rd Elgin IL 60123 (+1) 331 999 6367. [email protected]. Social Media Facebook .

Modern CNC machinery used for sheet metal processing grant top quality and efficiency of work in cases of complex workpieces. We have the potential of delivering full product fabrication by using CNC laser cutting, CNC puncing presses and press brakes and ofcourse the final processing of steel metal sheet workpieces, including all indurstiral surface treatments. surface .PBEH SERIES Heavy Duty CNC PANEL BENDER. Max. Bending Length: 1400-3000mm . Max. Sheet Width: 1400-1250mm . Max. Bending Height: 170mmLaser cutting is a metal fabrication process that uses a thin, computer-controlled laser to cut through metal—such as stainless steel, aluminum, and more. The material melts, burns, vaporizes, or is blown away by a jet of gas, leaving an .

Maximum precision levels are required whenever metal is being used. We automate your processes together in conjunction with you so that you can achieve your level of quality, productivity objectives, and create financially viable processes,. Integrated complete solutions create a revolutionary quality for thick sheet and thin sheet metal processing. Our own .

ESTABLISHED 2020 With a combined 30 years in the structural steel and sheet metal processing industry ABOUT US what we do. M.P.H. Metals Processing, Inc. was formed in 2020 with a core focus in providing the best available steel processing services for our customers. . Our comprehensive sheet metal and structural steel fabrication .3D solid sheet-metal CAD. Achieve an efficient three-dimensional sheet metal processing system to receive all your three-dimensional design CAD data. Information for shaping attributes and bending attributes is written automatically onto development diagrams created by SheetWorks for Unfold, enabling designs to be linked seamless to the CAM .The main activity of the company is mechanical production with focus on sheet metal processing, mainly punching, laser cutting, bending, welding, mounting and surface treatment by powder coat painting. We offer sheet metal products for wide scale of customers, also in small piece productions. The products are made by using top CNC machines . The technique of CGP was developed by Shin et al. [42].In the CGP process, a sheet specimen is subjected to orthogonal shear deformation by repetitive pressing under grooved dies and flat dies alternatively [42].Schematic diagram of CGP technique is shown in Fig. 1.Firstly, a pair of asymmetrically grooved dies which are tightly constrained by cylinder wall is .

Initially Chungpu focused on precision sheet metal processing and has over 30 years of experience in high-quality manufacturing. We are recognized as one of the proficient companies in Taiwan's machinery processing industry, known for our technical expertise. Our company specializes in metal plate processing, laser cutting, wire cutting, NCT .Machines to open holes and cut or weld thin sheets of metal (sheet metal) using a laser beam. Carbon dioxide lasers are often used for opening holes and cutting. A full line of oscillators is available for both fiber lasers (made in-house) and CO 2 lasers.

Cunpro Vietnam - Sheet Metal Processing & Fabrication, An Thuan, Song Be, Vietnam. 39 likes. CUNPRO Vietnam provides professional mechanical processing services with more than 15 years experience..We are The Steel Company, a sheet metal processing business with years of experience. Have a look at our website to discover more about us! We are The Steel Company, a sheet metal processing business with years of experience. . THE BEST IN SHEET METAL WORKING. OUR STRENGTHS. DIRECT COMMUNICATION.

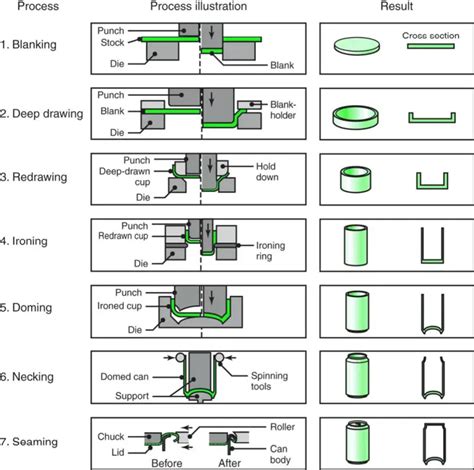

Sheet metal processing is a vast concept, covering several machining operations done to metal sheets. Since the topic is too broad, most people think the overall process only boils down to a single function. However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other .

types of sheet metal process

sheet metal utica ny

sheet metal union pay

$33.33

sheet metal processing|types of sheet metal process