what is gauge in sheet metal Sheet Metal Gauge Thickness Chart. When working with sheet metal, the term . Sheet metal parts are made with a constant thickness. They start out as one flat sheet and then are cut and bent to make the final product. When it comes to creating a sheet metal part in SOLIDWORKS you have two choices for the first step: converting to sheet metal or building up from a base.

0 · steel sheet gauge size chart

1 · sheet metal sizing chart

2 · sheet metal gauge vs thickness

3 · sheet metal gauge sizes chart

4 · printable sheet metal gauge chart

5 · metal plate thickness chart

6 · metal plate gauge thickness chart

7 · metal gauge size chart

The pallet-changing capability of the Haas VC-400 and VC-400SS allows you to machine parts on one pallet while loading/unloading parts on the other, boosting throughput and minimizing non-cutting time.

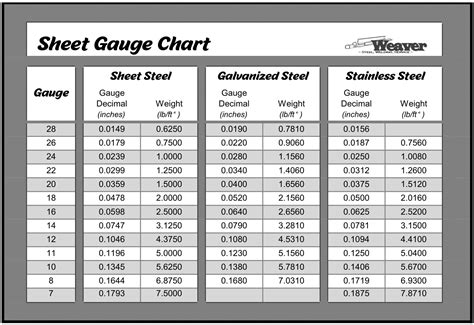

Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material.Pure metal / Used as an alloy element for aluminum, lead, zinc, and other . Sheet Metal Gauge Thickness Chart. When working with sheet metal, the term .The thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. Please note that ASTM states in specification ASTM A480-10a "The use of gage number is discouraged as being an archaic .

A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for . I find that 19 gauge is a bit stiff to work with for general body work. I use 18 for floor panels, 20 for areas where a bit of extra stiffness is desireable, like fenders, and 22 to 24 for general body work. The pre-fab body panels you can order are made from 22 to . With a sheet metal gauge chart (is shown in next part), you can convert the gauge size to mm or inch. Solution 1: Measuring Sheet Metal Thickness With Tape. There are three simple steps required in this, and they include: Step 1. Use the millimeter hash marks on your tape to find the thickness of sheet metal. Remember that there are two . Im getting ready to start replacing the floor pans in my 50 dodge and Ive been wondering what the best gauge sheet metal to replace them with. Ive noticed that repop floor pans are usually out of 16 to 18 gauge but a good friend of mine told me to use 10 or 12.. I know this is a total FNG question but cut me some slack. Thanks guys.

Metal Sheets at Tractor Supply Co. Buy online, free in-store pickup. . Pickup & Delivery Brand Price Gauge Finish All filters. 74 items in Metal Sheets. . Hillman SteelWorks 12 in. x 24 in. #26 Solid Steel Sheet, Zinc-Plated. 0 (0) | Item # 352107199. Pickup Today. FREE. Same Day Delivery. Standard Delivery .99. Sheet metal gauge and material type are critical considerations not only for vehicle design but also for repairs and modifications. Techniques in manipulation and repairing sheet metal, such as MIG welding, require precision in settings that correspond to the specific gauge and material of the metal. What gauge is the sheet metal on a 73 240. Im about to start my body work and it requires the cutting a replacing of some small areas of rust. . Agree with Tim on riding that thicker piece of sheet metal and momentarily dipping onto that thinner gauge for a deposit. I also like a fabricated flange to frame the sheet metal rather butt weld the . Go buy a sheet metal gauge and make your own decision. Makes it a lot easier to weld when both pieces are the same gauge. Different gauges are used for diff parts. . Since I'm currently in the process of doing sheet metal replacement and repair on a '66 coupe I can speak with current first hand knowledge. There were some areas on my coupe .

In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Most of the sheet metal I have measured on the bodies has been .020-.026 which comes out to a thinner gauge... Some of the bracing parts were thicker, maybe 16-18 ga. 18 Ga is much harder to work with in forming, hammer welding, and shrinking.

One sheet of 5/8" Type X sheetrock has no fire rating. But when it is used (one) on each side of a properly framed wall, it can become a fire rated wall. I am not aware of a fire rated wall assembly using sheet metal. Sheet metal penetrations are used in rated assemblies, and when correctly fire-caulked become part of that assembly. Sheet metal thickness gauges for steel are based on a weight of 41.82 pounds per square foot per inch of thickness. This is known as the Manufacturers’ Standard Gage for Sheet Steel. For other materials, such as aluminum and brass, the thicknesses will be different. The metal sandwiched together on the bottom inside of the rocker panels, some of it is .060 and .040 thick, so when you're working different panels and braces, be aware you have different thickness's of sheet metal. Also the rocker panels are galvanized, be aware of the fumes when welding or grinding, galvanized fumes are dangerous. What gauge or thickness for sheet metal? . Does anyone have a list of the original thicknesses for 1st Gen sheet metal? I have a number of "extra" front end pieces now and want to make sure which are OEM and which are aftermarket before I mislead someone accidentally. Cowl vent, fenders, valances, etc.

The gauge size is based on the weight of the metal sheet and is inversely proportional to the thickness, which means the higher it is, the thinner the sheet metal is. Gauges do not fall under imperial or metric measurement . The floors are heavier gauge than the fenders. On a SII I'm guessing the body is 18ga and the floors are 16 gauge. I used 14 gauge on my scout 800 for floors and some kick panel repair, and I can tell you 14ga is real hard to work with if you plan on any dolly and hammer work. The body mounts are probably 12 gauge. CHOOSING THE RIGHT GAUGE SHEET METAL FOR YOUR FABRICATION. Now moving into something that will be more specific to each customer and each sheet metal project. This is choosing the right thickness, or gauge, of sheet metal. It is very important that you are using the correct product to optimize efficiency and functionality. In order to measure .

If you have a set of calipers you can measure the thickness of the existing metal and then order what you need. Here's some of the common gauges and corresponding thickness of sheet steel: GA. Thickness 12 - 0.1046 13 - 0.0897 14 - 0.0747 15 - 0.0673 16 - 0.0598 17 - 0.0538 18 - 0.0478 19 - 0.0418 20 - 0.0359 21 - 0.0329 22 - 0.0299 The problem with using the same gauge metal as the original is that when you grind down the welds, the remaining sheet metal can become paper thin. You have to be very careful when grinding. I learned to use thicker, 16 gauge, metal on some patches. This way I have extra metal to grind down and shape. A sheet metal gauge is a standard unit of measure used to determine the thickness of a metal sheet. The gauge number and thickness have an inverse relationship – the higher the gauge number, the thinner the sheet. For instance, 10-gauge aluminum is 0.1019” thick, while 18-gauge aluminum is 0.040” .

I put 16 gauge floor panels in the one I'm working on now, with a framework of 3/4" 1/8"-wall square tubing to support it so there aren't any large spans of metal to act like noisy drum heads. It has a real solid feel. In another car, I used 18 gauge for the floor. use whatever gauge the metal you are working with is. I always laugh when the mini truck guys pay for a door handle shave kit and it has a plate twice as thick as the door skin on their s10. THey wonder why you can see a imprint of the handle when the temp changesThis sub is for tool enthusiasts worldwide to talk about tools, professionals and hobbyists alike. We welcome posts about "new tool day", estate sale/car boot sale finds, "what is this" tool, advice about the best tool for a job, homemade tools, 3D printed accessories, toolbox/shop tours.Sheet metal gauge chart: We supply Full Sheets, Part Sheets, Cut to Size and CNC shape cutting, we can take DXF and most common file types. We can TIG weld Copper, Brass, Bronze and Stainless, and MIG weld Aluminium, Corten and Mild Steel. Zinc and Pewter are soldered. Information on zinc gauge (zg) is also given on this page.

youtube installing metal pigeon nest box

A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the metal in thousandths of an inch. Gauge thickness applies differently depending on the metal type, which is confusing but just how it is. Ferrous and non-ferrous metals, for example, classified by the same gauge, actually . I use 18 gauge sheet metal for most of my repairs. Old cars generally were made with 19 gauge, but that is hard to get from most suppliers. 20 is the default gauge for vendors when working around this because it saves them $$$, but I find that panel warp is better controlled with 18 gauge.

steel sheet gauge size chart

sheet metal sizing chart

sheet metal gauge vs thickness

At its core, metal fabrication involves cutting, shaping, and assembling metal materials to create structures or products. This versatile process is the backbone of countless industries and contributes to the creation of everything .

what is gauge in sheet metal|metal plate gauge thickness chart