how to fold wire in electrical box Once that’s on, fold it into the box; it may help to manipulate the other wires in the box. We’ll repeat the same thing for these two wires. Some of these workboxes are set up to have dividers installed in them for separate circuits. It’s not always necessary, but it’s a good idea for safety. To weld thin metal, choose an appropriate process (TIG or MIG with low amperage), use a smaller diameter wire or filler rod, and adjust travel speed to prevent burn-through. Employ a pulsing technique, stitch welding, or .

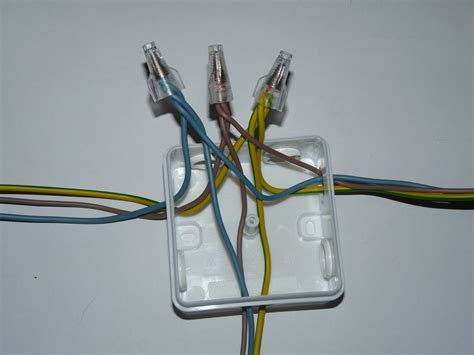

0 · wire nuts for electrical box

1 · wire in electrical boxes

2 · packing wire into device box

3 · folding cables into electrical box

4 · folding cables into boxes youtube

5 · folding cables into boxes

6 · fitting wires in electrical box

7 · electrical box wiring diagram

Harbor Freight Gasless Flux Core Welder Mods - Run a 10lb Spool of Wire! Can You Flux Core Weld 22 Gauge Steel? Go Gasless! See How Simple MiG Welding Can Be. We’ve been using this.

How to fold wires into an electrical box. MDO VIDEO. 1.44K subscribers. Subscribed. 133. 33K views 4 years ago. how to fold wires into a box to keep ground wires away from current carrying terminals consult codes before doing electrical work .more. You can try to fold the wires to the back of the box, which should help, but to some extent you're really counting on the splice to be secure. Wire nut connections when done right are very secure, but there is some skill / . Connect them up and carefully arrange them neatly in the box, leaving a "hole" for the device and minimal wire for the device, roughly positioned where they will connect to the .

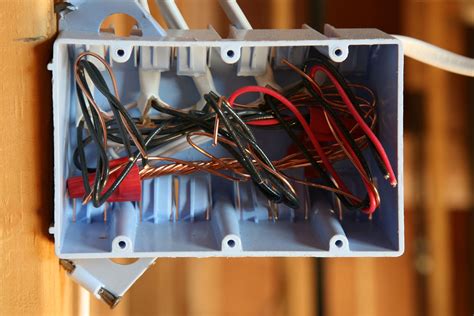

Once that’s on, fold it into the box; it may help to manipulate the other wires in the box. We’ll repeat the same thing for these two wires. Some of these workboxes are set up to have dividers installed in them for separate circuits. It’s not always necessary, but it’s a good idea for safety. Fit the Wires in the Box . Carefully fold the wires into the box. Install the box cover, securing it with two screws. Code requires that the cover must be a solid "blank" without holes. Restore power to the circuit by switching . If you’ve done much wiring, you’ve probably run into the issue of an overstuffed electrical box. Here’s how to ensure a neat and compact box. First, gather all the bare ground wires along with a long pigtail and connect them. . A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

Push the Wires into the Box. Fold and pack the wires neatly into the box to conserve space and reduce pressure on connections. Label wires with scraps of cable sheathing. Electrical plans are a roadmap to project success. .When you’re putting the wire nut on, it helps to keep your finger in that corner so that you can get a good twist on the bundle. You’ll know when to stop twisting the wire nut when you can twist the bundle a bit more. Once that’s on, fold it into the box; it may help to manipulate the other wires in . Pretty simple really. I believe when making up any device box,,it is most efficient to "fold" wires into a box. 2 bends in the wire, if looking at the profile of the wires connecting to the device it would form an "N",,, A less experienced guy I work withs swears that the way he "rolls" his wires into the box is better. 2 "rolls" towards the box,,profile would be a big "O". how to fold wires into a box to keep ground wires away from current carrying terminals consult codes before doing electrical work.

wire nuts for electrical box

Looking for a quick and easy way to fold a wire container? Look no further! In this video, I'll show you how to do it in just three easy steps. You'll be don.

Difference Between a Single and Double Gang Box (and Larger) Please read my how to splice a single gang box tutorial, as I won’t be repeating all of that here!. What’s important to talk about a double gang box and larger is where to enter wires in a box, and using the corners of the box for the most space.. Before moving on, here’s a pro-tip! I show how to use the carlon handy box to install a outlet no romex connector needed how to fold wires into a box keeping ground wire away from live and neut.

Use the deepest, largest box you can fit in the wall, with the most cubic inches. Metal boxes have more cubic inches than plastic boxes. "Masonry" boxes are huge, and well worth the trouble. Trim every wire that comes into that box to about 7" length. That allows you to fold the wire into the box with one 180-degree bend. Learn how to set up wires for switches in a 3 gang switch box with this YouTube video tutorial. Fit the Wires in the Box . Carefully fold the wires into the box. Install the box cover, securing it with two screws. Code requires that the cover must be a solid "blank" without holes. Restore power to the circuit by switching on the circuit breaker.The electrical cable should be installed so that 1 inch of sheathing is inside the electrical box and 6 inches of wire is showing outside of the electrical box. . Step 4: Fold The Ground Wires Carefully Back Into The Junction Box: Fold the ground wires and push them back into the box keeping the last one out. Straighten out the wires and trim .

wire in electrical boxes

Folding electrical wire? help I have a switch box and the wire I have (1mm) is too thin to be secured by the screws in the back box. Is it ok to fold the wire back on itself to double the thickness, and secure it that way? Share Add a Comment. Sort .

Fold them into the back of the box, leaving the pigtail extended. Next, do the same for the neutral wires. If you’re connecting switches (as shown here) you don’t need a neutral pigtail. Leave the hot wire extra long and fold it back and forth across the bottom of the electrical wire box. Put a wire connector cap on the hot wire to identify it.Welcome to /r/Electricians Reddit's International Electrical Worker Community aka The Great Reddit Council of Electricians Talk shop, show off pictures of your work, and ask code related questions. . If it's a brand new box I try to fold them in in some way like this, usually left to right green white then phase colors (black red blue) or .

metal baluster ideas for hill country style house

Wiring a outletGiven many of these switches utilize wires connected to the unit itself (vs screw terminals), they require 3-5 wire nuts, and then I just end up shoving the unit back inside the wall box and the wires look like a mess, and I generally have a .

Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also se. In that case, remove the box, remove the wires, get a deeper old work box, and try again. Or, better, cut the opening for a 2 gang or 4” box, and add another device. You double or triple your volume for the price of another pigtail and outlet.How to fold wires into electrical box?Let me give you a brief introduction of who I am, Hey, I am Delphi. I help you answer your questions. - How to fold wir.

Now connect the neutral (white) wires, then the hot (black) wires, following the procedures outlined in Step 4. Give the wire nuts a tug to make sure they’re on tight and there are no loose wires. 6. Finish the Installation. Carefully and neatly fold the joined wires back into the box. Place the cover onto the box front and tighten the screws. Ensuring Proper Wire Fold: Arrange the wires to neatly fold back into the box and secure the outlet with screws. Final Touches: Affix the wall plate to complete the installation. This technique with the Wago 221 can simplify the task, especially when dealing with shorter wires where traditional wire nuts may be challenging. I show how to install a GFCI outlet with 4 wires. I'm putting this GFCI in a grounded metal electrical box in the Chicago area. Ground wires aren't used, the.

packing wire into device box

If you are wiring houses, it is near impossible not to fold them into the box, doing it properly comes with practice. In the millions (?) of houses in the US, I would bet those wired by a skilled tradesman, leaving the NEC mandated lengths, 99% are . Learn how to install an electrical outlet from a junction box. In this video tutorial, I will show you how to wire an electrical outlet and how to wire the e.

You reach the maximum number of conductors in the box well before you run out of knock out space. I double up sometimes for 3 cable boxes because it's easier to lay the wires neatly in the box if they are all going the same direction. If you're looking to wire an electrical metal box, then you've come to the right place! In this video, we'll teach you the basics of wiring a metal box, incl.How to Work Efficiently in an Electrical Box, Part 3. After wires are organized in a switch box, it's time to bundle and label them so you know what's what when you come back to install the switches. How to Install a Single-Pole Light Switch. Learn how to cut, strip, and connect the ground, neutral, and hot wires for a basic light circuit. . *DISCOUNT on the Sense Home Energy Monitor for Subscribers using code BENJAMIN!* http://store.sense.com/discount/BENJAMINMy Favorite Tool: https://amzn.to/3N.

folding cables into electrical box

folding cables into boxes youtube

folding cables into boxes

To weld thin metal, choose an appropriate process (TIG or MIG with low amperage), use a smaller diameter wire or filler rod, and adjust travel speed to prevent burn-through. Employ a pulsing technique, stitch welding, or tack welds to manage heat and allow cooling periods between welds to minimize warping.

how to fold wire in electrical box|folding cables into electrical box