electrical distribution box design The voltage drop in distribution system is calculated by following Ohm,s Law. Let us consider a simple do radial distribution system as shown in Figure 9. The system have concentrated . See more Wholesale Sheet Metal has been a trustworthy and reliable source of heating, ventilating, air conditioning and sheet metal products in our market for over 35 years. Our courteous and professional staff with unparalleled service has made us an industry leader.

0 · types of electrical distribution boards

1 · temporary power distribution box

2 · power distribution box for generator

3 · home electrical distribution box

4 · electrical power distribution boxes

5 · electrical distribution box types

6 · electrical distribution box components

7 · distribution box with circuit breaker

A wholesale sheet metal deep drawn part factory specializes in producing high-quality deep drawn parts for a variety of industries. Deep drawing is a manufacturing process that involves shaping flat sheet metal into complex and three-dimensional shapes.Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. It allows for superior quality components, produced at high speeds, and often at lower costs than competing methods.

Now-a-days electrical energy is generated, transmitted and distributed in the form of alternating current. One important reason for the widespread use of alternating current in preference to direct current is the fact that alternating voltage can be conveniently changed in magnitude by means of a transformer. . See more

It is a common knowledge that electric power is almost exclusively generated, transmitted and distributed as AC However, for certain . See more

types of electrical distribution boards

temporary power distribution box

A considerable amount of effort is necessary to maintain an electric power supply within the requirements of various types of consumers. . See moreThe voltage drop in distribution system is calculated by following Ohm,s Law. Let us consider a simple do radial distribution system as shown in Figure 9. The system have concentrated . See moreNorth American distribution boards are generally housed in sheet metal enclosures, with the circuit breakers positioned in two columns operable from the front. Some panelboards are provided with a door covering the breaker switch handles, but all are constructed with a dead front; that is to say the front of the enclosure (whether it has a door or not) prevents the operator of the circuit breakers from contacting live electrical parts within. Busbars carry the current from incoming line .When considering the design of an electrical distribution system for a given customer and facility, the electrical engineer must consider alternate design approaches that best fit the following overall goals. 1. Safety: The No. 1 goal is to design a power system that will not present any electrical hazard to the people who

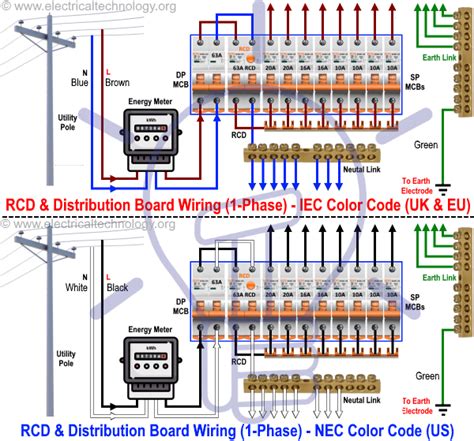

Electrical panels designed to split an incoming mains supply into multiple smaller circuits are usually designed as either single-phase or 3-phase distribution boards. Single-phase and three-phase are different methods of .In today’s step-by-step guide, we will demonstrate how to select the right size panelboard (whether it’s a load center, distribution board, or circuit breaker panel) according to NEC and IEC standards, with worked examples. Related Post: .Distribution boxes, also known as junction boxes, electrical boxes, or panelboards, are essential components in electrical distribution systems. They serve as protective enclosures for the connections, splices, and terminations .ABB Mini Center Compact distribution boards are the basis for development and growth in meeting all the demands for a successful future in residential, commercial, and infrastructure segments.

Thanks to the new-generation LayoutFAST toolset from Schneider Electric™, specifiers, engineers, and contractors can quickly and easily design, generate, and share BIM objects. The upgraded design tools make more .Our innovative distribution systems serve as the primary electrical hub for any industrial infrastructure, dividing power into subsidiary circuits and safeguarding each with protective fuses or breakers.Power distribution boxes, or PDUs, are essential for efficiently distributing electrical power to various equipment and devices in industrial and commercial settings. They come in different sizes and configurations, featuring multiple .

Electrical distribution systems are an essential part of the electrical power system. In order to transfer electrical power from an alternating current (AC) or a direct current (DC) source to the place where it will be used, some type of distribution network must be utilized.A distribution board (also known as panelboard, circuit breaker panel, breaker panel, electric panel, fuse box or DB box) is a component of an electricity supply system that divides an electrical power feed into subsidiary circuits while providing a protective fuse or circuit breaker for each circuit in a common enclosure.When considering the design of an electrical distribution system for a given customer and facility, the electrical engineer must consider alternate design approaches that best fit the following overall goals. 1. Safety: The No. 1 goal is to design a power system that will not present any electrical hazard to the people who

Electrical panels designed to split an incoming mains supply into multiple smaller circuits are usually designed as either single-phase or 3-phase distribution boards. Single-phase and three-phase are different methods of connecting outside mains power into a building, and each has its pros and cons in certain situations.In today’s step-by-step guide, we will demonstrate how to select the right size panelboard (whether it’s a load center, distribution board, or circuit breaker panel) according to NEC and IEC standards, with worked examples. Related Post: How to .Distribution boxes, also known as junction boxes, electrical boxes, or panelboards, are essential components in electrical distribution systems. They serve as protective enclosures for the connections, splices, and terminations of electrical wires and cables.ABB Mini Center Compact distribution boards are the basis for development and growth in meeting all the demands for a successful future in residential, commercial, and infrastructure segments.

power distribution box for generator

Thanks to the new-generation LayoutFAST toolset from Schneider Electric™, specifiers, engineers, and contractors can quickly and easily design, generate, and share BIM objects. The upgraded design tools make more detailed information available from conception to completion, multiplying efficiencies and lowering potential risks.Our innovative distribution systems serve as the primary electrical hub for any industrial infrastructure, dividing power into subsidiary circuits and safeguarding each with protective fuses or breakers.Power distribution boxes, or PDUs, are essential for efficiently distributing electrical power to various equipment and devices in industrial and commercial settings. They come in different sizes and configurations, featuring multiple outlets, circuit breakers, and . Electrical distribution systems are an essential part of the electrical power system. In order to transfer electrical power from an alternating current (AC) or a direct current (DC) source to the place where it will be used, some type of distribution network must be utilized.

A distribution board (also known as panelboard, circuit breaker panel, breaker panel, electric panel, fuse box or DB box) is a component of an electricity supply system that divides an electrical power feed into subsidiary circuits while providing a protective fuse or circuit breaker for each circuit in a common enclosure.When considering the design of an electrical distribution system for a given customer and facility, the electrical engineer must consider alternate design approaches that best fit the following overall goals. 1. Safety: The No. 1 goal is to design a power system that will not present any electrical hazard to the people who

Electrical panels designed to split an incoming mains supply into multiple smaller circuits are usually designed as either single-phase or 3-phase distribution boards. Single-phase and three-phase are different methods of connecting outside mains power into a building, and each has its pros and cons in certain situations.

In today’s step-by-step guide, we will demonstrate how to select the right size panelboard (whether it’s a load center, distribution board, or circuit breaker panel) according to NEC and IEC standards, with worked examples. Related Post: How to .Distribution boxes, also known as junction boxes, electrical boxes, or panelboards, are essential components in electrical distribution systems. They serve as protective enclosures for the connections, splices, and terminations of electrical wires and cables.ABB Mini Center Compact distribution boards are the basis for development and growth in meeting all the demands for a successful future in residential, commercial, and infrastructure segments. Thanks to the new-generation LayoutFAST toolset from Schneider Electric™, specifiers, engineers, and contractors can quickly and easily design, generate, and share BIM objects. The upgraded design tools make more detailed information available from conception to completion, multiplying efficiencies and lowering potential risks.

Our innovative distribution systems serve as the primary electrical hub for any industrial infrastructure, dividing power into subsidiary circuits and safeguarding each with protective fuses or breakers.

home electrical distribution box

electrical power distribution boxes

electrical distribution box types

electrical distribution box components

HEAD SHEET METAL SCREWS Zinc Plated. Shop at Fascofas.com for many types of Screws and get FREE UPS GROUND Delivery and LOW PRICES. We specialize in wholesale bulk .

electrical distribution box design|electrical distribution box types