cnc machine condition monitoring Overall, these studies demonstrate the potential of IIoT-based condition monitoring for enhancing machining process efficiency, reducing maintenance costs, and improving . Plastic vs. metal boxes: Use a metal junction box with metal-sheathed cable .

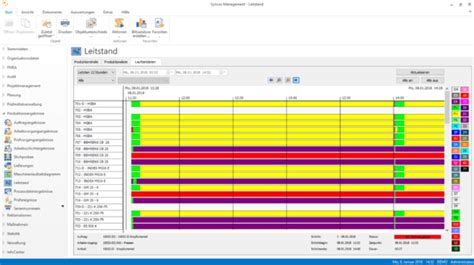

0 · real time production monitoring

1 · real time machine monitoring

2 · machine run time tracking

3 · machine monitoring system for manufacturing

4 · equipment monitoring system dashboard

5 · cnc machine monitoring systems

6 · cnc machine data collection

7 · best cnc machine monitoring software

u/vedui made a really nice mod for A18 that adds “wireless” junction boxes. Probably wont solve wires 100%, but cuts way down on traffic. You an hide them by modding the DLL, or adding an electrical item, that is not yet defined in the game, like a fusebox or even a doorknow that can be connected electrically. That makes wires also disappear.

This study aims to monitor conditions of four CNC machines from different places simultaneously using Internet of things (IoT) for predictive maintenance. Vibration signals of .Overall, these studies demonstrate the potential of IIoT-based condition .Predictive maintenance (PdM) or condition-based monitoring is an advanced . Overall, these studies demonstrate the potential of IIoT-based condition monitoring for enhancing machining process efficiency, reducing maintenance costs, and improving .

Predictive maintenance (PdM) or condition-based monitoring is an advanced diagnostic technique to reveal the operating machinery faults in their incipient phase before . Condition monitoring of machines employs sensors and data analysis techniques to assess equipment health by monitoring parameters like vibration, temperature, and lubricant condition, enabling early fault detection . In this paper, a framework to establish a baseline reference dataset is proposed utilizing vibration monitoring and time domain statistical feature analysis. The framework was .Monitor machine conditions (faults, status, tool utilization), production (OEE & Machine Utilization), work-order status, quality tracking and downtime reasons that can be auto classified or indicated by the operator with touch screen .

This paper presents a multiple sensor-based condition and availability monitoring system deployed on a CNC machine. The major steps for preventive maintenance are daily checking . Results showed that acceleration signal in both time and frequency domains can identify conditions of each machine in real time and simultaneously monitor the condition of four CNC machines at.Arrow and ADLINK — in collaboration with Intel, Microsoft, and SAS — are bringing to market a machine condition monitoring (MCM) solution that aims to revolutionize the way manufacturing .

Abstract: We developed a CNC machine's condition monitoring system based on Artificial Neural Network (ANN) and correlate the same with the real-time CNC machine data. The . This study aims to monitor conditions of four CNC machines from different places simultaneously using Internet of things (IoT) for predictive maintenance. Vibration signals of four CNC machines are measured using an accelerometer to collect and send signals directly to the database in real time. Overall, these studies demonstrate the potential of IIoT-based condition monitoring for enhancing machining process efficiency, reducing maintenance costs, and improving product quality in various manufacturing applications. The IIoT .

Predictive maintenance (PdM) or condition-based monitoring is an advanced diagnostic technique to reveal the operating machinery faults in their incipient phase before any breakdowns occur. Therefore, required maintenance can . Condition monitoring of machines employs sensors and data analysis techniques to assess equipment health by monitoring parameters like vibration, temperature, and lubricant condition, enabling early fault detection and predictive maintenance. In this paper, a framework to establish a baseline reference dataset is proposed utilizing vibration monitoring and time domain statistical feature analysis. The framework was applied as a case study in a newly commissioned linear axis testbed.Monitor machine conditions (faults, status, tool utilization), production (OEE & Machine Utilization), work-order status, quality tracking and downtime reasons that can be auto classified or indicated by the operator with touch screen tablet interfaces mounted at the machine tool.

real time production monitoring

This paper presents a multiple sensor-based condition and availability monitoring system deployed on a CNC machine. The major steps for preventive maintenance are daily checking of lubricant level, inspecting of vibration levels, and temperature of the motor. Results showed that acceleration signal in both time and frequency domains can identify conditions of each machine in real time and simultaneously monitor the condition of four CNC machines at.Arrow and ADLINK — in collaboration with Intel, Microsoft, and SAS — are bringing to market a machine condition monitoring (MCM) solution that aims to revolutionize the way manufacturing stakeholders manage machine assets.Abstract: We developed a CNC machine's condition monitoring system based on Artificial Neural Network (ANN) and correlate the same with the real-time CNC machine data. The classification of the condition of a CNC machine was done by deciding whether it is a fresh machine or worn machine using machine learning techniques.

This study aims to monitor conditions of four CNC machines from different places simultaneously using Internet of things (IoT) for predictive maintenance. Vibration signals of four CNC machines are measured using an accelerometer to collect and send signals directly to the database in real time.

Overall, these studies demonstrate the potential of IIoT-based condition monitoring for enhancing machining process efficiency, reducing maintenance costs, and improving product quality in various manufacturing applications. The IIoT .

Predictive maintenance (PdM) or condition-based monitoring is an advanced diagnostic technique to reveal the operating machinery faults in their incipient phase before any breakdowns occur. Therefore, required maintenance can . Condition monitoring of machines employs sensors and data analysis techniques to assess equipment health by monitoring parameters like vibration, temperature, and lubricant condition, enabling early fault detection and predictive maintenance.

In this paper, a framework to establish a baseline reference dataset is proposed utilizing vibration monitoring and time domain statistical feature analysis. The framework was applied as a case study in a newly commissioned linear axis testbed.Monitor machine conditions (faults, status, tool utilization), production (OEE & Machine Utilization), work-order status, quality tracking and downtime reasons that can be auto classified or indicated by the operator with touch screen tablet interfaces mounted at the machine tool.

This paper presents a multiple sensor-based condition and availability monitoring system deployed on a CNC machine. The major steps for preventive maintenance are daily checking of lubricant level, inspecting of vibration levels, and temperature of the motor.

Results showed that acceleration signal in both time and frequency domains can identify conditions of each machine in real time and simultaneously monitor the condition of four CNC machines at.

Arrow and ADLINK — in collaboration with Intel, Microsoft, and SAS — are bringing to market a machine condition monitoring (MCM) solution that aims to revolutionize the way manufacturing stakeholders manage machine assets.

optical fiber distribution box suppliers

real time machine monitoring

Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also se.

cnc machine condition monitoring|real time machine monitoring