automobile sheet metal fabrication forum Forums - FabricationForum.com To summarise: figure out what you need from your electrical junction box and work backwards from there. As each type of electrical junction . See more

0 · automotive sheetmetal

1 · Why Sheet metals with Embossing operation is not used for

2 · What thickness or gauge is standard automotive sheetmetal

3 · Vehicle Builds

4 · General Metal Shaping Discussion

5 · FabricationForum.com

6 · Fabricating automotive body parts, where would one begin?

7 · Automotive Projects

8 · Autobody Welding and Sheet Metal Fab. Tips/ Tricks

9 · All MetalShaping

On a typical Sheet Metal Work job description, their listed duties may include measuring and marking raw materials, cutting sheet metal to desired sizes using specialized equipment and fastening sheet metal into place via soldering, welding and other techniques.

A forum to discuss everything related to welding, fabricating and CNC cutting.A forum to discuss everything related to welding, fabricating and CNC cutting.Forums - FabricationForum.comMembers - FabricationForum.com

Activity stream for all registered members at FabricationForum.com.General Fabrication - FabricationForum.comDIY Projects. Post all of your Projects and Builds here - photos and videos welcome!Discuss everything related to CNC cutting! Search titles only; Posted by Member: .

All things welding in here! Search titles only; Posted by Member: Separate names .See what Motobilt out of Dothan, AL is up to! See their latest innovative projects .Contest entry. Off road independent suspension trailer. Costa Fabrications .

This is the forum to ask or answer basic metal shaping questions. Hopefully the topics in this forum will become a resource for new shapers where answers to frequently . All MetalShaping > Metal Shaping Projects: Automotive Projects User Name: Remember Me? Password: Register: All Albums: Event Calendar: Today's Posts . Page 1 of . Contest entry. Off road independent suspension trailer. Costa Fabrications 80 series land cruiser bumper. (You must log in or sign up to post here.)

Before you do any fabricating you should remove all of the rust, paint and old filler, then treat the metal with a rust remover, or inhibitor, or converter and then spray the clean . Topics related to safety issues in the typical metal shapers environment. Welding, lighting, chemicals, material handling, etc. What thickness or gauge is standard automotive sheetmetal on American vehicles, such as a door skin or fender skin. I'm practicing up on my Mig and am trying to determine .You can take two paths to you goal, sheet metal or fiberglass. I would try fiberglass first. You can just add material to an existing part and sand it down to get the shape you want. Sheet metal .

automotive sheetmetal

Automotive sheet metal is usually more like 18 to 20 gauge. There must be local area sources for sheet metal in your area. Also look for metal surplus places, you can usually .Embossing operation in sheet metal increases rigidity, yield stress, tensile stress. Why they are not used in automobile parts (on sided embossing and other side plain) ? This operation will . A forum to discuss everything related to welding, fabricating and CNC cutting. This is the forum to ask or answer basic metal shaping questions. Hopefully the topics in this forum will become a resource for new shapers where answers to frequently asked questions are found 5-in-1 Welder & Cutter.

All MetalShaping > Metal Shaping Projects: Automotive Projects User Name: Remember Me? Password: Register: All Albums: Event Calendar: Today's Posts . Page 1 of 43: 1: 2: 3: 11 > Last » Threads in Forum: Automotive Projects: Forum Tools : Rating Thread / Thread Starter: Last Post: Replies: Views: 1938 Pontiac Silver Streak Touring Sedan .

Contest entry. Off road independent suspension trailer. Costa Fabrications 80 series land cruiser bumper. (You must log in or sign up to post here.)

Before you do any fabricating you should remove all of the rust, paint and old filler, then treat the metal with a rust remover, or inhibitor, or converter and then spray the clean bare metal with an epoxy primer/sealer to stop any future rust. Topics related to safety issues in the typical metal shapers environment. Welding, lighting, chemicals, material handling, etc.

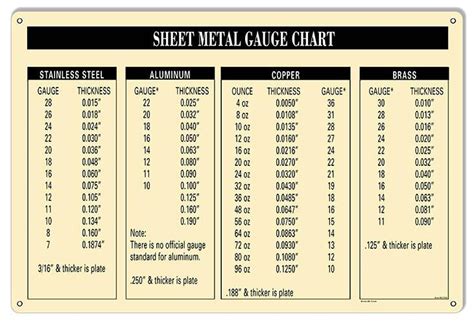

What thickness or gauge is standard automotive sheetmetal on American vehicles, such as a door skin or fender skin. I'm practicing up on my Mig and am trying to determine settings, using ER70-6S and C25. The tables in my texts and on the machine reference gauge. Thanks for any info. You can take two paths to you goal, sheet metal or fiberglass. I would try fiberglass first. You can just add material to an existing part and sand it down to get the shape you want. Sheet metal requires numerous and expensive tools, along with a substantial skill set to use them.

Automotive sheet metal is usually more like 18 to 20 gauge. There must be local area sources for sheet metal in your area. Also look for metal surplus places, you can usually find sheet metal for a reasonable price per pound there. A sheet metal fabrication shop would probably sell you some if you asked nicely.

Embossing operation in sheet metal increases rigidity, yield stress, tensile stress. Why they are not used in automobile parts (on sided embossing and other side plain) ? This operation will allow thin sheet panels to be used resulting in reduced weight.

A forum to discuss everything related to welding, fabricating and CNC cutting. This is the forum to ask or answer basic metal shaping questions. Hopefully the topics in this forum will become a resource for new shapers where answers to frequently asked questions are found 5-in-1 Welder & Cutter. All MetalShaping > Metal Shaping Projects: Automotive Projects User Name: Remember Me? Password: Register: All Albums: Event Calendar: Today's Posts . Page 1 of 43: 1: 2: 3: 11 > Last » Threads in Forum: Automotive Projects: Forum Tools : Rating Thread / Thread Starter: Last Post: Replies: Views: 1938 Pontiac Silver Streak Touring Sedan .

Contest entry. Off road independent suspension trailer. Costa Fabrications 80 series land cruiser bumper. (You must log in or sign up to post here.) Before you do any fabricating you should remove all of the rust, paint and old filler, then treat the metal with a rust remover, or inhibitor, or converter and then spray the clean bare metal with an epoxy primer/sealer to stop any future rust.

Topics related to safety issues in the typical metal shapers environment. Welding, lighting, chemicals, material handling, etc. What thickness or gauge is standard automotive sheetmetal on American vehicles, such as a door skin or fender skin. I'm practicing up on my Mig and am trying to determine settings, using ER70-6S and C25. The tables in my texts and on the machine reference gauge. Thanks for any info. You can take two paths to you goal, sheet metal or fiberglass. I would try fiberglass first. You can just add material to an existing part and sand it down to get the shape you want. Sheet metal requires numerous and expensive tools, along with a substantial skill set to use them. Automotive sheet metal is usually more like 18 to 20 gauge. There must be local area sources for sheet metal in your area. Also look for metal surplus places, you can usually find sheet metal for a reasonable price per pound there. A sheet metal fabrication shop would probably sell you some if you asked nicely.

corrugated metal sheet fence

Why Sheet metals with Embossing operation is not used for

A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm.

automobile sheet metal fabrication forum|All MetalShaping