what is zone 22 mean for electrical enclosures Motors characterised as “Increased Safety” Ex ec or ex eb, are used on industrial zone 22 explosion proof fans. Ex ec is the lowest and most normal level of Ex protection, .

Westminster Metal Fabricators design, supply and install metal gates and railings to meet every need. Whether you are in the market for a decorative or purposeful security gate, we can help. All of our fabricators are .

0 · nema enclosures

1 · atex zone 22 zoning

2 · atex zone 22

3 · atex dust zone 22

Order MK Logic Plus 45A Unswitched Cooker Outlet Plate White at Screwfix.com. Screwfix customers rate this product 4.4/5. FREE next day delivery available, free collection in 1 minute.

nema enclosures

The ATEX rating is a technical standard developed to minimize the risk of explosions caused by electrical or non-electrical equipment, like safety cameras, safety fans, safety lighting, mobile devices, and others.Zone 22 - A location in which an explosive atmosphere in the form of a cloud of combustible dust in the air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.A strategy like targeted ventilation can often serve as an effective and budget-friendly method for zone reduction. Our experience includes cases where ATEX zone 0 was downgraded to ATEX zone 2 solely through improved ventilation. . The ATEX directive uses zones to classify potentially explosive gas and dust atmospheres. Classifications range from an ignitable condition being an unlikely occurrence (Zones 2 and 22) to continuously present (Zones 0 and 20).

ATEX Zone 22 Definition – What is Zone 22? A Zone 22 area is classified as an atmosphere where a mixture of air and flammable substances in the form of powder or dust is not likely to occur in normal operation, but if it does occur, . Motors characterised as “Increased Safety” Ex ec or ex eb, are used on industrial zone 22 explosion proof fans. Ex ec is the lowest and most normal level of Ex protection, .

discount sheet metal fabrication machinery quotes

Addresses recommended criteria to determine ignitibility hazards in chemical process areas using flammable liquids, gases, or vapors to assist in the selection of electrical systems and .Zone 22 is defined as an area in which an explosive dust atmosphere, in the form of a cloud of dust in the air, is not likely to occur in normal operation but, if it does occur, will persist for a .Subdivisions and classification of gases and vapours. Conditions and Zone classification. Flammable Temporary behaviour materials of explosive atmosphere. Required marking on the .• a “Type of protection ‘d’ ” marking (IEC Zone System). — 01 This diagram illustrates the escape paths of gases generated by an explosion within an electrical enclosure. When an explosion occurs, hot or burning gases pass through the threaded joint or Star Teck XP flame path and must make a number of changes in direction. These

The choice of electrical enclosure material will usually be dictated by the environment in which the enclosure will be used. Electrical Enclosure Accessories. The electrical enclosure construction also includes an array of .ATEX Zone 2, 22 Zone 2, 22 means that there is no hazardous material present, but if there is, it is for less than 10 hours a year and in low concentration. The hazardous area industry has been stuck in the past for decades by large .

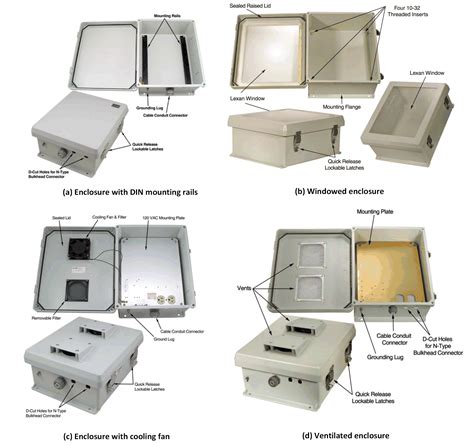

Read our comprehensive overview, detailing all ATEX zones, groups, and categories. . Within Europe, electronic or electrical equipment of any kind that is intended for use in a potentially hazardous area must be ATEX-certified, as per the EU directive 2014/34. This directive is more commonly known as theZone 0: An area where an explosive atmosphere is present continuously or for long periods of time. Equipment used in this zone must be of explosion-proof or intrinsic safety design, and personnel must be trained in the safe use of the equipment. Zone 1: An area where an explosive atmosphere is likely to occur in normal operation. Equipment used . It is fully conductive and compliant with ATEX Directive 2014/34/EU: ISO 80079-36:2016 and ISO 80079-37, meaning it is safe to use in ATEX Zones 1,2, 21 and 22. This is our simplest, most accessible ATEX system and is the fastest way of removing combustible dust. Electrical enclosures are specialized housings designed to protect electrical equipment from environmental factors and human interference. They come in various shapes and sizes, crafted from metal or plastic to suit different settings. . What do you mean by enclosure in electrical? . 22 Pioneer Crescent #02-06 West Park BizCentral Singapore .

An IP (Ingress Protection) rating is used by buyers in Europe to specify the extent of protection an electrical enclosure has against environmental conditions. The IP rating system was established by the International Electromechanical Commission (IEC), a worldwide organization for standardization. The object of the IEC is to promote .

The European standard EN 60529 dated October 1991, IEC publication 529 (2nd edition - November 1989), defines a coding system (IP code) for indicating the degree of protection provided by electrical equipment enclosures against accidental direct contact with live parts and against the ingress of solid foreign objects or water.

There are four zones, with Zone 1 being the least threatened by seismic activity, and Zone 4 being the most threatened (ie. areas near an active fault line). Telcordia determines these zones and issues the standards that seismic enclosures must meet, with .X type purge systems are used in a Division 1 area where non-hazardous rated equipment will be installed inside of the enclosure. For ATEX and IECEx Zone rated applications, purge systems are designated pz, py and px. Zone ratings and applications are similar to the previously described Division 1 and 2 area ratings. IP ratings are extremely important as they indicate environments in which casings and enclosures of electrical and electronic products are safe to use. . For example, when a device has an IP 54 rating, this means that the enclosure is adequately protected against dust and water splashes. Another example could be an IP 68 rating which means .

atex zone 22 zoning

Polycase SA Series: Another NEMA 2 enclosure line that goes far above and beyond the rating requirements, the SA Series are stainless steel enclosures that offer true professional protection for your electrical and electronic equipment. Their stainless steel construction makes them highly resistant to scratching and rust.Schneider Electric USA. Browse our products and documents for Walk-In Enclosures (Power-Zone Center) - Custom designed enclosure designed for the protection of equipment in an outdoor or adverse environment. . I'd like to receive news and commercial info from Schneider Electric and its affiliates via electronic communication means such as .

We are a manufacturer of UL listed outdoor enclosures. We have always painted our products gray, the same as all other electrical enclosures. I have a customer who wants a significant number of enclosures painted green. At first I thought why not, but then I thought, why are enclosures always.Zone 22 is defined as an area in which an explosive dust atmosphere, in the form of a cloud of dust in the air, is not likely to occur in normal operation but, if it does occur, will persist for a short period only. Ignition sources must be prevented .Hot spots are commonly occurring thermal phenomena and refer to areas within electrical enclosures that are not cooled by the forced convection. It is impossible to say where hot spots might occur in an enclosure because the layout, heat . Grasp the meaning and significance of ATEX rating; . Adoption of Zone 1-compliant electrical equipment, heightened safety precautions: ATEX Regulation in the EU. . Zone 20, Zone 21, Zone 22: Agriculture: Grain dust, organic dust: Zone 20, Zone 21, Zone 22: Mining: Methane, coal dust:

What does this mean for you : . -Zone 22: area in which an . -An electrical enclosure is a cabinet for electrical or electronic equipment to mount switches, knobs and displays and to prevent .d. The wiring and equipment installation within the methane zone or the methane buffer zone shall be based on Level V design, if the measured gas concentration is not known. e. The wiring and equipment installation within the methane zone or the methane buffer zone shall be based on soil gas pressure more than 2 inches of water column, if the

A Zone 22 area is classified as an atmosphere where a mixture of air and flammable substances in the form of powder or dust is not likely to occur in normal operation, but if it does occur, will persist for a short period only.

Electrical Engineering general discussion . Enclosures and I/O in hazardous zones. Thread . My biggest confusion with enclosures is I have been told that if the enclosure is rated for a particular zone, it doesn't matter what is inside, as long as the wiring glands, cable coming out of the box, and panel controls are rated for the same zone. . Common Sizes. Enclosures are normally classified into three sizes – small, medium and large. Small Enclosures: These enclosures have dimensions of 75 x 125 x 35 mm to 150 x 200 x 100 mm. Medium Enclosures: They range from 150 x 200 x 100 mm to 300 x 600 x 136 mm and give extra room for accommodating more components. Big Enclosures: These .

How do NEMA enclosures protect electrical and electronic devices? . CSA Standard 22.2 No. 94 - Special Purpose Enclosures; Intertek offers listings and marks for enclosure products, including ETL, c-ETL, and us-ETL. The ETL mark is recognized in both the U.S. and Canada. . NEBS Zone 4 Enclosures or Seismic NEMA Enclosures .Dirt, dust, water—all “adversaries” of electrical products due to the potential damage they can cause. To help protect products from these elements, the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) have created classification systems designating different degrees of protection, depending on the .Specifically it is a special purpose hydraulic press, but the only thing needing NRTL is the electrical box containing the motor starter and 24V PSU for the externally housed control module. The electrical enclosure fits inside of an oddly shaped stand and presents the start and stop buttons in a convenient location, which is not achievable .

atex zone 22

atex dust zone 22

There are several advantages of fabrication shop drawings that help to keep things right at construction sites. 1. Your engineers and . See more

what is zone 22 mean for electrical enclosures|atex dust zone 22