cnc lathe machine maintenance pdf The TM6, TM8, and TM10 machines are described in this manual. Machine linear positioning accuracy was set at the factory, in an ambient temperature of 68º F (20º C). Continual operation at higher or lower temperatures may require that you . You can always count on United Sheet Metal and Air Conditioning to get to you fast and get the job done right the first time. We use state-of-the-art diagnostic equipment to find the source of your heating and air conditioning problems and fix them fast.

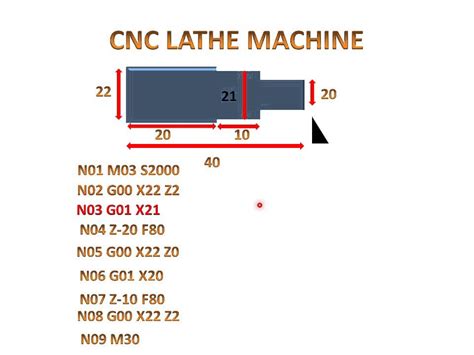

0 · cnc turning program examples PDF

1 · cnc turning machine programming PDF

2 · cnc turning cycle program PDF

3 · cnc programming for dummies PDF

4 · cnc programming PDF free download

5 · cnc machine parts list PDF

6 · cnc machine operation manual PDF

7 · cnc lathe manual PDF

Marvel Metal Universe Avengers Trading Cards merges throwback inspiration with new thematic designs and technology to showcase fan favorite characters from the Marvel Avengers Publishing Universe!. Collect the 100-card Light FX base set; Find beautiful colored ratioed parallels; Precious Metal Gems; Chase a variety of themed inserts including:

The TM6, TM8, and TM10 machines are described in this manual. Machine linear positioning accuracy was set at the factory, in an ambient temperature of 68º F (20º C). Continual .daily and weekly basis to ensure the proper maintenance and performance of a Haas lathe can be achieved. Morning Tasks: Apply 3 pumps of grease to the hydraulic chuck at each zerk fitting. .

By following this preventive maintenance guide, you can minimize unexpected breakdowns, optimize machine performance, and extend the lifespan of your CNC machine. Download our PDF guide for easy reference, and keep your CNC machine running smoothly.The TM6, TM8, and TM10 machines are described in this manual. Machine linear positioning accuracy was set at the factory, in an ambient temperature of 68º F (20º C). Continual operation at higher or lower temperatures may require that you .

daily and weekly basis to ensure the proper maintenance and performance of a Haas lathe can be achieved. Morning Tasks: Apply 3 pumps of grease to the hydraulic chuck at each zerk fitting. Check hydraulic pressure gauges. Ensure they are set to the correct operating levels. Warm up spindle. Run spindle at 500 RPM for 5 min.%PDF-1.6 %âãÏÓ 48 0 obj > endobj 78 0 obj >/Filter/FlateDecode/ID[79644E9ED713974EAD06729C4A0774FC>381F0A93FB75BF4399553C204C6B0914>]/Index[48 52]/Info 47 0 R .

STEP 1: • Check the oil level daily. STEP 2: • Check the speed control knob for looseness and smooth operation. STEP 3:• Clean the worktable surface periodically with a damp rag to remove metal chips, swarf, or dust. STEP 4: • Avoid dropping tools or workpieces into the headstock; they could get caught in gears and damage them.CNC DAILY MAINTENANCE CHECKLIST.xlsx - Free download as Excel Spreadsheet (.xls / .xlsx), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document provides a daily preventive maintenance check list for a CNC machine.

This machine is two axis CNC lathe with drum type turret, and has the following features. (1) Enables both chuck and center works. (2) Uses AC built-in motor to directly change the speed in a wide range [5,5/7,5 kW (SKT100),

Normal user alignment, adjustment, tuning and machine settings are not covered by this warranty. It is the responsibility of the user to understand basic machinery operation, settings and procedures and to properly maintain the equipment in accordance with the standards provided by the manufacturer.View and download Cnc lathe manuals for free. H6D-T instructions manual.HAAS CNC MACHINE TOOL PREVENTIVE MAINTENANCE CHECKLIST © 2021 Haas Automation, Inc. | www.HaasCNC.com | 805-278-1800 MECHANICAL SYSTEM Verify machine levelBy following this preventive maintenance guide, you can minimize unexpected breakdowns, optimize machine performance, and extend the lifespan of your CNC machine. Download our PDF guide for easy reference, and keep your CNC machine running smoothly.

The TM6, TM8, and TM10 machines are described in this manual. Machine linear positioning accuracy was set at the factory, in an ambient temperature of 68º F (20º C). Continual operation at higher or lower temperatures may require that you .

metal fabrication cleveland oh

cnc turning program examples PDF

daily and weekly basis to ensure the proper maintenance and performance of a Haas lathe can be achieved. Morning Tasks: Apply 3 pumps of grease to the hydraulic chuck at each zerk fitting. Check hydraulic pressure gauges. Ensure they are set to the correct operating levels. Warm up spindle. Run spindle at 500 RPM for 5 min.%PDF-1.6 %âãÏÓ 48 0 obj > endobj 78 0 obj >/Filter/FlateDecode/ID[79644E9ED713974EAD06729C4A0774FC>381F0A93FB75BF4399553C204C6B0914>]/Index[48 52]/Info 47 0 R .

STEP 1: • Check the oil level daily. STEP 2: • Check the speed control knob for looseness and smooth operation. STEP 3:• Clean the worktable surface periodically with a damp rag to remove metal chips, swarf, or dust. STEP 4: • Avoid dropping tools or workpieces into the headstock; they could get caught in gears and damage them.CNC DAILY MAINTENANCE CHECKLIST.xlsx - Free download as Excel Spreadsheet (.xls / .xlsx), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document provides a daily preventive maintenance check list for a CNC machine.This machine is two axis CNC lathe with drum type turret, and has the following features. (1) Enables both chuck and center works. (2) Uses AC built-in motor to directly change the speed in a wide range [5,5/7,5 kW (SKT100),

Normal user alignment, adjustment, tuning and machine settings are not covered by this warranty. It is the responsibility of the user to understand basic machinery operation, settings and procedures and to properly maintain the equipment in accordance with the standards provided by the manufacturer.

View and download Cnc lathe manuals for free. H6D-T instructions manual.

cnc turning machine programming PDF

metal fabrication carlock il

$64.00

cnc lathe machine maintenance pdf|cnc turning machine programming PDF