draw operation in sheet metal However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. The following are key elements affecting metal flow, and each of them should .

Luxury watch box. 8-piece watch storage. Removable soft cushions. Suitable for all TW Steel styles

0 · simple sheet metal drawings

1 · sheet metal operations with diagrams

2 · sheet metal operation pdf

3 · sheet metal deep drawing calculations

4 · shearing operation in sheet metal

5 · embossing operation in sheet metal

6 · deep drawing metal forming process

7 · deep draw blank size calculation

The CableGuard CG-1000XL Demarcation Enclosure provides a UL Listed and .

Drawing Operation: Once the metal sheet is clamped securely, it’s drawn or pulled over the die, resulting in the metal sheet taking the shape of the die. Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, . These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels . Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to .

Starting with the 2D cutting process needed to make a blank, then exploring forming operations necessary for various sheet metal features, and finally concluding with finishing and assembly considerations as well as how to . However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. The following are key elements affecting metal flow, and each of them should .Deep Drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. We can consider a component as the deep-drawn if the depth of the .

Deep drawing of sheet metal is performed with a punch and die. The punch is the desired shape of the base of the part, once drawn. The die cavity matches the punch and is a little wider to allow for its passage, as well as clearance. This .Common parts made by sheet metal drawing include beverage cans, ammunition shells, sinks, cooking pots, and automobile body panels. Sides of punch and die are separated by a . Drawing Operation: Once the metal sheet is clamped securely, it’s drawn or pulled over the die, resulting in the metal sheet taking the shape of the die.

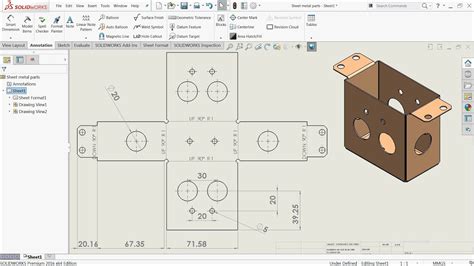

simple sheet metal drawings

Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking Operations; Punching Operations; Piercing Operations; Trimming Operations; Drawing Operations; Embossing Operations; Bending Operations; Squeezing Operations #1 Shearing Operation. It is cut in a straight line across a . Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.

Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.Starting with the 2D cutting process needed to make a blank, then exploring forming operations necessary for various sheet metal features, and finally concluding with finishing and assembly considerations as well as how to ensure your team puts out good designs that your manufacturers can understand and make at a high quality.

electrical outlet ceiling box

However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. The following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies:Deep Drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. We can consider a component as the deep-drawn if the depth of the drawn .Deep drawing of sheet metal is performed with a punch and die. The punch is the desired shape of the base of the part, once drawn. The die cavity matches the punch and is a little wider to allow for its passage, as well as clearance. This setup is similar to sheet metal cutting operations.Common parts made by sheet metal drawing include beverage cans, ammunition shells, sinks, cooking pots, and automobile body panels. Sides of punch and die are separated by a clearance c. It is given as: Deformation stages in deep drawing are illustrated in figure (3-66).

Drawing Operation: Once the metal sheet is clamped securely, it’s drawn or pulled over the die, resulting in the metal sheet taking the shape of the die. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking Operations; Punching Operations; Piercing Operations; Trimming Operations; Drawing Operations; Embossing Operations; Bending Operations; Squeezing Operations #1 Shearing Operation. It is cut in a straight line across a . Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information.

These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.

Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.Starting with the 2D cutting process needed to make a blank, then exploring forming operations necessary for various sheet metal features, and finally concluding with finishing and assembly considerations as well as how to ensure your team puts out good designs that your manufacturers can understand and make at a high quality. However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. The following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies:Deep Drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. We can consider a component as the deep-drawn if the depth of the drawn .

Deep drawing of sheet metal is performed with a punch and die. The punch is the desired shape of the base of the part, once drawn. The die cavity matches the punch and is a little wider to allow for its passage, as well as clearance. This setup is similar to sheet metal cutting operations.

sheet metal operations with diagrams

electrical outlet remodel box

electrical outlet boxes you can use for commercial

How two women sought to preserve the unique sounds of the Twin Towers and created their own audio memorial to the World Trade Center.

draw operation in sheet metal|embossing operation in sheet metal