sheet metal how to bend a box How To Bend Sheet Metal Without A Brake: How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools. Discover the key differences between Vertical Machining Centers (VMCs) and Horizontal Machining Centers (HMCs), exploring their pros, cons, applications, setup times, and output.

0 · sheet metal bending dies

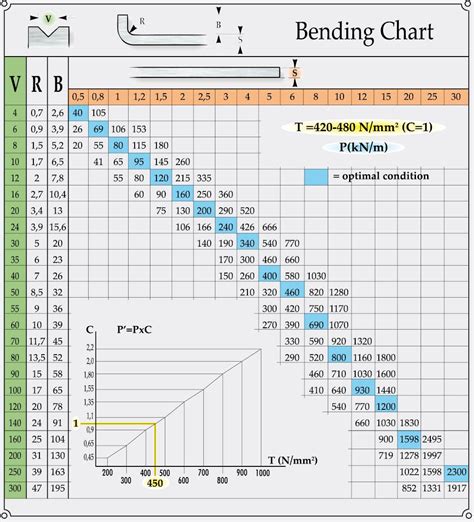

1 · sheet metal bending chart

2 · sheet metal bending by hand

3 · how to bend metal professionally

4 · folding sheet metal at home

5 · bending operation in sheet metal

6 · bending 16 gauge sheet metal

7 · bend sheet metal without brake

Electrical Junction Box, Outdoor Water Resistant Nema Enclosure, Ventilated ABS Plastic WiFi Project Box with Internal Mounting Panel & Hinged Cover 9.2" Lx 7" Wx 4.6" H

sheet metal bending dies

Creating a 22 gauge sheetmetal box from scratch. Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan brake .

Once the hems have been made the next step is to bend your metal into a box. You will be working with a sheet metal brake to complete this step. The goal here is to clamp your brake . How To Bend Sheet Metal Without A Brake: How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.10. 516 views 5 months ago. How to make a sheet metal box with simple tools, no brake press or bender. .more.

junction box watertight

sheet metal bending chart

It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

This is not the real world. It's maths pretending to be real things. You use a plane, extrude an edge and then bevel the corner to get the curve you would expect from a sheet metal bender. Lob a solidify modifier on top and hey presto - . This week, Brycen gives advice on how to make metal bends on a sheet metal brake. Learn how to easily create parts that can nest in each other without making. http://amzn.to/12cdkoZ Here Ron Fournier shows us the first steps on how to use a box pan brake bending machine to make a box: First you have to set the brak.Defining Sheet Metal Bending. Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with. The bending process alters the sheet metal’s shape without changing its .

Learn how to make rounded bends with a sheet metal brake in this informative video tutorial.

In this HVAC Training Video, I show How to Make a Sheet Metal Plenum in the Field! I Bend the Metal Cross Brakes and 90's with a piece of Plywood! I Show the.im just a hobbyist and need to bend 1/16 sheet metal 4 times as seen below. all dimensions are in inches. going from left to right, the bends are 1, up 1.7, over 1.7, down 1.7, and over 1. i saw this Irwin bend tool to make the first 1 inch bend but no idea how to make subsequent bends Calculate your bend allowance. The bending you will be doing will warp your sheet metal so that it is physically bigger. To calculate the expansion that will take place on the outside of your bend angle, you will need to know your bend allowance.

TIG Welding and fabricating my new mailbox out of aluminum sheet metal. Had to do all my bending without a brake. This is a great first sheet metal project. . How To Make A Metal Project Enclosure:How To Make A Metal Project Enclosure with thin sheet metal.For more info on bending metal - https://youtu.be/KdMtecvnP. This is another great beginner sheet metal project I use in my shop classes. I use it to teach print reading skills and order of operations to my students. .

junction box trains

Learn how to use a pan and box brake to bend sheet metal in a variety of ways. Learn how to make a hem on sheet metal to reduce sharp edges and create a more.

Using sheet metal file to create a box

With X-Press SuperCustom, bending deep boxes like tanks, sinks, and cooking equipment has never been easier. Shorten fabrication cycles, avoid unnecessary co.

In this HVAC Training Video, I Show a Fast Forward Process of Creating a 26 Gauge Sheet Metal Plenum Box for Supply or Return Ducting on a Gas Furnace or Air. BUY The Versa-Bend MetaL Brake Here: https://www.eastwood.com/eastwood-versa-bend-sheet-metal-brake.html?utm_source=youtube&utm_medium=annotation&utm_campai.Troubleshooting common issues in sheet metal bending. While sheet metal bending is rewarding, it can also present some challenges. With our expertise and years of experience, Shengen has faced and overcome various issues. Understanding and solving these issues is essential for the final product to be of the highest possible quality. Sheet metal hand brakes are used to bend sheet metal for roofing and other purposes. This 15-minute instructional video was filmed at the 2018 Slate Roofing .

A simple one piece tool tray is shown being fabricated from scrap metal. The process highlights the way dimensions of the box come to life by cutting the ap. This is quick & simple tutorial for solidworks beginners starting working with sheet metal. DXF ready for metal fabricator shop!Follow simple steps to learn .

1.4 Deep box bending with 30°–60° degree tooling; 2 Got a deeper box? No problem! 3 Sheet Metal Bend Gains Chart. 3.1 BEND GAINS CHART DOWNLOAD; 4 Deep Forming Sheet Metal FAQ. 4.0.1 What challenges do sheet metal fabricators face when forming deep boxes? 4.0.2 How does Approved Sheet Metal address deep forming issues for customers? Making A metal Box Out Of Sheet Metal Hi Friends. NAMASTE. Welcome To The Fab2ku Family.Friends..Let's make a box from sheet metal today. The. #sheetmetal Sheet Metal Design Sheet Metal FabricationSheet Metal Do you want to become an expert of Modeling on SolidWorks, then this video exactly for you..

How to make a sheet metal box with simple tools, no brake press or bender. When there are two (or sometimes three) bends that meet in a corner, like a tray or box, the relief is often called “corner relief.” In both cases, the idea is the same: to remove enough material from the edge of the bend that the bend can be formed. . More information on best practices for sheet metal bending. #ventilation #sheetmetal #hvac #ductworkSheet metal boxes are versatile and functional, serving a variety of purposes across industries such as electronics, automotive, and HVAC. Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. . A sheet metal brake or bending tool . A drill with appropriate bits . Fasteners (rivets, screws, or .

sheet metal bending by hand

$12.98

sheet metal how to bend a box|sheet metal bending chart