cnc machine oee MachineMetrics has simplified IoT machine monitoring for the shop floor: our fully automated CNC machine monitoring systems & OEE software provides visualizations of real-time manufacturing production data, instant notifications, as well as historical analytics, allowing factory workers to make faster, smarter, more confident decisions based on .

Whether you need a power distribution box that’s compact for easy movement like the Bento Box® Doghouse featuring end plate grips for easy handling in tight spaces or the Lunchbox featuring a collapsible handle, end plate grips, and easy vertical or horizontal mounting options.With our additional cable strain relief ring for junction boxes, strain relief can easily be complemented to installations. Our tutorial shows how quickly th.

0 · how to calculate oee

1 · cnc machine monitoring tool

2 · cnc lathe schedule

3 · cnc lathe manual

$19.49

Overall equipment effectiveness (OEE) provides a means to measure the percentage of productive planned manufacturing time. By measuring OEE, you gain insight into optimal productivity challenges and how to improve .

Overall Equipment Effectiveness (OEE) is a performance measure commonly used to monitor successful improvements to a process/area/machine. OEE is .

MachineMetrics has simplified IoT machine monitoring for the shop floor: our fully automated CNC machine monitoring systems & OEE software provides visualizations of real-time .

Overall equipment effectiveness (OEE) provides a means to measure the percentage of productive planned manufacturing time. By measuring OEE, you gain insight into optimal productivity challenges and how to improve your manufacturing operations.Overall Equipment Effectiveness (OEE) is a performance measure commonly used to monitor successful improvements to a process/area/machine. OEE is designed to indicate how effectively a manufacturing operation is utilised.MachineMetrics has simplified IoT machine monitoring for the shop floor: our fully automated CNC machine monitoring systems & OEE software provides visualizations of real-time manufacturing production data, instant notifications, as well as historical analytics, allowing factory workers to make faster, smarter, more confident decisions based on .DataXchange OEE software delivers real-time CNC machine monitoring & automated shop floor data collection to increase overall equipment effectiveness.

Predator MDC is real-time machine monitoring software that automatically collects, reports, charts and processes real-time shop floor manufacturing data including OEE, cycle time, idle time, setup time, teardown time, machine downtime and more.Reduce machine downtime & increase shop floor productivity with DataXchange CNC Machine Monitoring & OEE Software. Schedule a Free Demo Now.

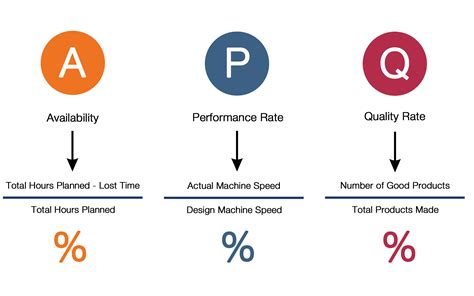

Any organization can achieve consensus about the right machine data for OEE by breaking down and considering the three distinct OEE components. To calculate AVAILABILITY, divide machine runtime by planned production time. Establish machine run time using basic machine signals: cycle, hold, mode, spindle (normalized)OEE, or Overall Equipment Effectiveness, is a brilliant invention that, in a single number, tells you how much waste there is on your shop floor. It is the ratio of what you produced to what you could have produced – the actual output to the theoretical possible output. At United Scientific, our CNC operators understand the ins and outs of overall equipment effectiveness. OEE is a metric we use to improve our efficiency regularly. Join us as we break down the components of OEE and show you what to .

Features of OEE machine monitoring include: Production data, analytics, and visuals come together to help you optimize your plant’s performance. Assess operator productivity using hardware, firmware, and software all connected to the machine. Cost-effective, and compatible with all machines – CNC, non-CNC, PLC, presses, injection molding, etc. Overall equipment effectiveness (OEE) provides a means to measure the percentage of productive planned manufacturing time. By measuring OEE, you gain insight into optimal productivity challenges and how to improve your manufacturing operations.Overall Equipment Effectiveness (OEE) is a performance measure commonly used to monitor successful improvements to a process/area/machine. OEE is designed to indicate how effectively a manufacturing operation is utilised.MachineMetrics has simplified IoT machine monitoring for the shop floor: our fully automated CNC machine monitoring systems & OEE software provides visualizations of real-time manufacturing production data, instant notifications, as well as historical analytics, allowing factory workers to make faster, smarter, more confident decisions based on .

square stainless steel tissue box cover

DataXchange OEE software delivers real-time CNC machine monitoring & automated shop floor data collection to increase overall equipment effectiveness.Predator MDC is real-time machine monitoring software that automatically collects, reports, charts and processes real-time shop floor manufacturing data including OEE, cycle time, idle time, setup time, teardown time, machine downtime and more.

Reduce machine downtime & increase shop floor productivity with DataXchange CNC Machine Monitoring & OEE Software. Schedule a Free Demo Now.

Any organization can achieve consensus about the right machine data for OEE by breaking down and considering the three distinct OEE components. To calculate AVAILABILITY, divide machine runtime by planned production time. Establish machine run time using basic machine signals: cycle, hold, mode, spindle (normalized)

squiggle metal brackets to join wood

OEE, or Overall Equipment Effectiveness, is a brilliant invention that, in a single number, tells you how much waste there is on your shop floor. It is the ratio of what you produced to what you could have produced – the actual output to the theoretical possible output. At United Scientific, our CNC operators understand the ins and outs of overall equipment effectiveness. OEE is a metric we use to improve our efficiency regularly. Join us as we break down the components of OEE and show you what to .

how to calculate oee

cnc machine monitoring tool

ss metal box

In this video, we delve into the fascinating world of sheet metal forming and explore the intricate process behind it. From the basics to the advanced techni.

cnc machine oee|cnc lathe schedule