cnc lathe machine g code pdf This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi. Lan guage: .

ABC Manufacturing is one of the leading wholesale vertical milling machine CNC manufacturers in the market. They specialize in producing robust machines equipped with advanced CNC technology. Their machines offer superior precision, high .

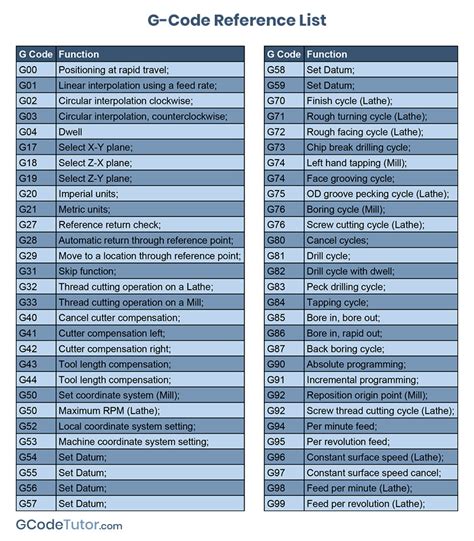

0 · list of g codes cnc

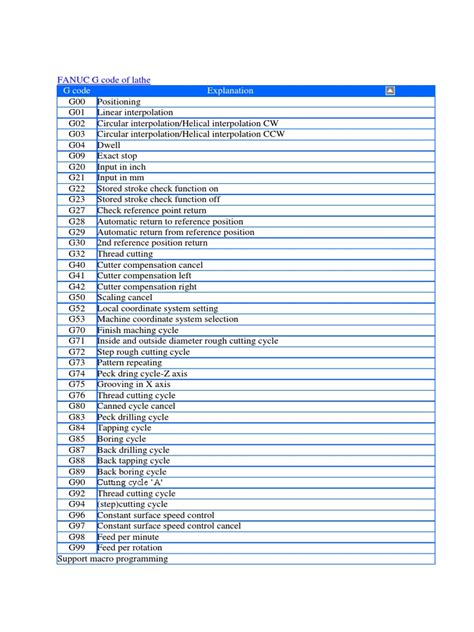

1 · list of fanuc g codes

2 · cnc turning g code list

3 · cnc mill g code list

4 · cnc lathe g codes list

5 · cnc lathe g code examples

6 · cnc g code list download

7 · cnc g code chart

Why ground a metal box? My understanding is MC cable contains a copper wire for grounding back to the panel, just like NM cable. If that is so, what is the purpose of tying the metal box .

Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. –

list of g codes cnc

list of fanuc g codes

A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and .This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi. Lan guage: .Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC .

g51 return to machine zero, cancel offset (yasnac) g52 work offset coordinate positioning (yasnac) g52 global work coordinate system shift (fanuc) g53 machine coordinate positioning, non .

G00 - Positioning at rapid speed; Mill and Lathe G01 - Linear interpolation (machining a straight line); Mill and Lathe G02 - Circular interpolation clockwise (machining arcs); Mill and LatheG Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download. Due to the different styles of G-code, it’s necessary to understand how .

sheet metal fabrication waterford

cnc turning g code list

sheet metal fabrications

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. –A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in .

This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi. Lan guage: European English. Paper size: A4 (210mm x 297mm). Denford Customer Services. Tel: +44 (0) 1484 722733. e-mail: customer_services @denford.co.uk.

Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training?g51 return to machine zero, cancel offset (yasnac) g52 work offset coordinate positioning (yasnac) g52 global work coordinate system shift (fanuc) g53 machine coordinate positioning, non-modal (x,z,b) g54 work offset coordinate positioning #1 (setting 56) g55 work offset coordinate positioning #2 g56 work offset coordinate positioning #3G00 - Positioning at rapid speed; Mill and Lathe G01 - Linear interpolation (machining a straight line); Mill and Lathe G02 - Circular interpolation clockwise (machining arcs); Mill and Lathe

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download. Due to the different styles of G-code, it’s necessary to understand how .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.

cnc mill g code list

G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).

GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. –

A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in .

This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi. Lan guage: European English. Paper size: A4 (210mm x 297mm). Denford Customer Services. Tel: +44 (0) 1484 722733. e-mail: customer_services @denford.co.uk.Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training?g51 return to machine zero, cancel offset (yasnac) g52 work offset coordinate positioning (yasnac) g52 global work coordinate system shift (fanuc) g53 machine coordinate positioning, non-modal (x,z,b) g54 work offset coordinate positioning #1 (setting 56) g55 work offset coordinate positioning #2 g56 work offset coordinate positioning #3

sheet metal fabrication symbol

I have always felt that best practice is to locate jboxes above the insulation if possible. But that locating them below the insulation is not a violation because you are not "damaging the building structure or finish" if you need to access them.

cnc lathe machine g code pdf|list of g codes cnc